Fast beam smoothing method based on beam dynamic interference patterns in inertially confinement fusion device

A technology of inertial confinement fusion and dynamic interference, which is applied in the field of fast beam smoothing based on beam dynamic interference pattern, can solve the problems of high cost and difficult realization of pump light, and can reduce focal spot, improve irradiation uniformity, avoid The effect of intensity modulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

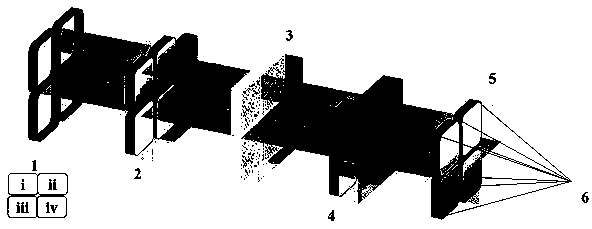

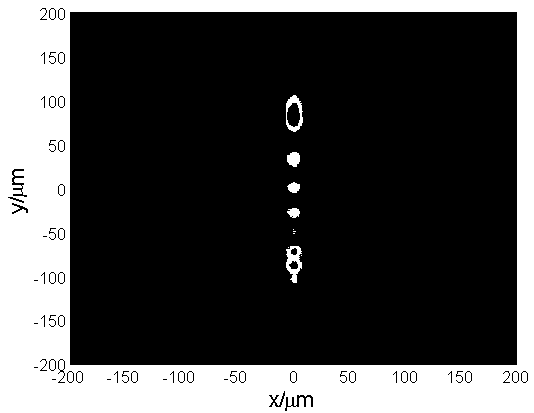

[0037]The conjugated phase plate used in this embodiment is a tilted phase plate with a phase PV (peak-to-valley) value of 2λ (λ=351nm) and an aperture of 372mm×372mm. To achieve a comparable effect to 2D-SSD, the tilted phase plates of sub-beams i and ii are tilted along the x direction, while the tilted phase plates of sub-beams iii and iv are tilted along the y direction. The working wavelength of each sub-beam in the laser beam is λ i =λ iii =351nm,λ ii =λ iv =351.1nm, the polarization states of sub-beam i and sub-beam ii are x-line polarization, and the polarization states of sub-beam iii and sub-beam iv are both y-line polarization. The integration time is 10ps.

[0038] Figure 2 shows the phase distribution of the conjugated phase plate, which can be but not limited to oblique phase, cylindrical phase, spherical phase and helical phase. This embodiment adopts the oblique phase in (a).

[0039] For the convenience of comparison, the fast beam smoothing method of Exa...

Embodiment 2

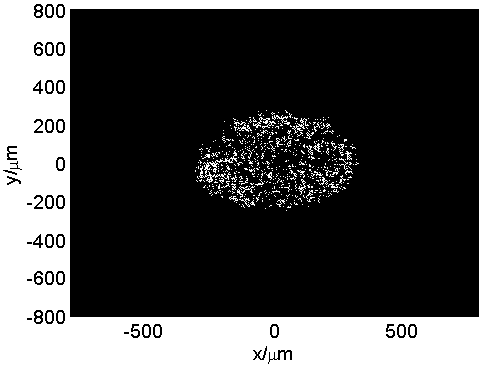

[0056] The conjugated phase plate used in this embodiment is a cylindrical phase plate with a phase PV (peak-to-valley) value of 2λ (λ=351nm) and an aperture of 372mm×372mm. In order to achieve a comparable effect to 2D-SSD, the cylindrical phase plates of sub-beams i and ii are aligned along the x direction, while those of sub-beams iii and iv are aligned along the y direction. The working wavelength of each sub-beam in the laser beam is λ i =λ iii =351nm,λ ii =λ iv =351.2nm, the polarization states of sub-beam i and sub-beam ii are x-line polarization, and the polarization states of sub-beam iii and sub-beam iv are both y-line polarization. The integration time is 5ps. The other operation steps and operation process are the same as in Embodiment 1, and the same effect of improving the uniformity of the far-field focal spot of the laser beam as in Embodiment 1 can be obtained.

[0057] Use formulas (4) and (5) to calculate the luminous flux contrast ratio of the focal sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com