Aluminum wire collecting and stripping machine

A wire stripping machine and aluminum wire technology, applied in recycling technology, electronic waste recycling, cable installation devices, etc., can solve the problems of easily hurting people's hands, cumbersome operation, etc., and achieve the effect of good peeling and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

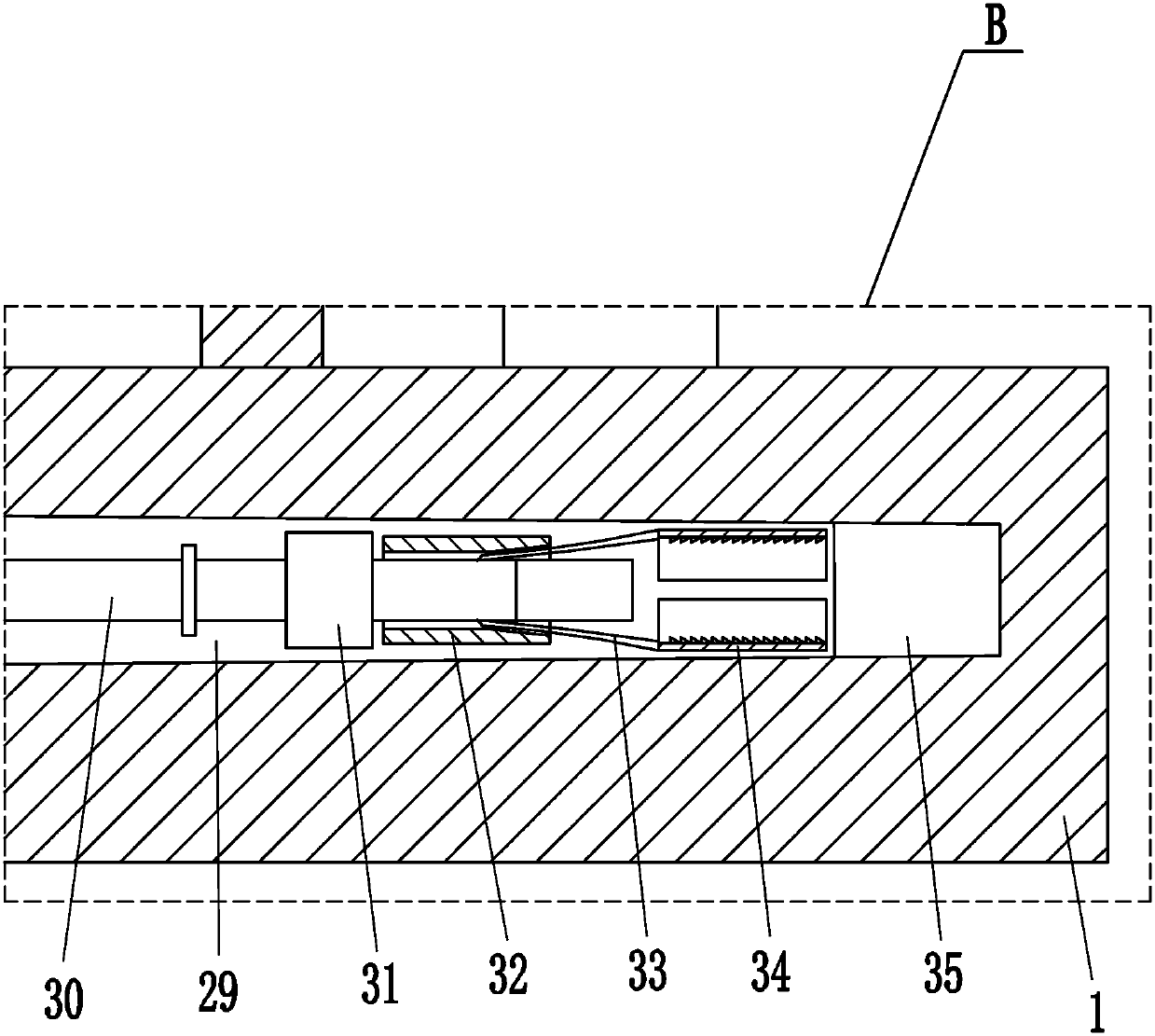

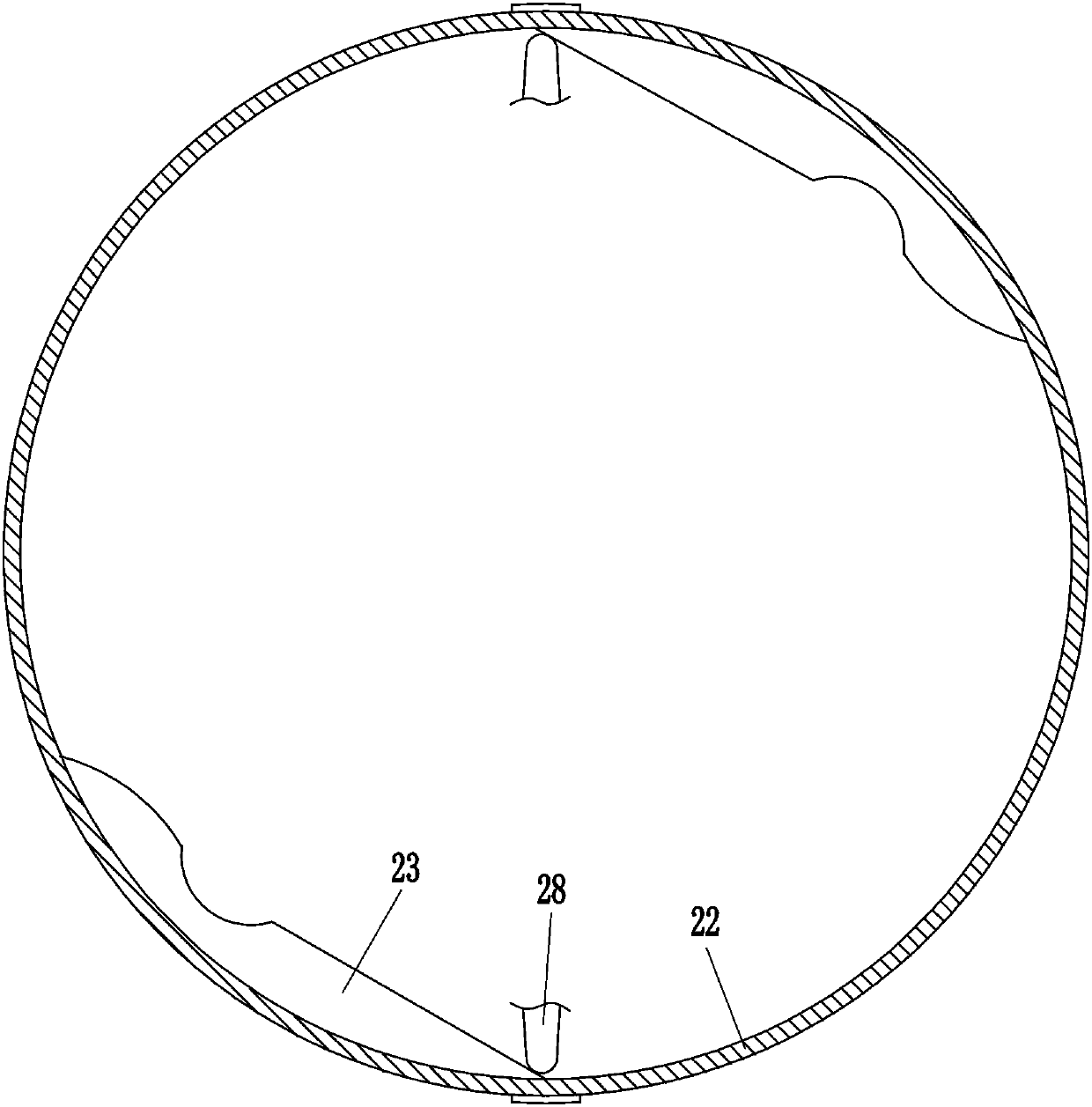

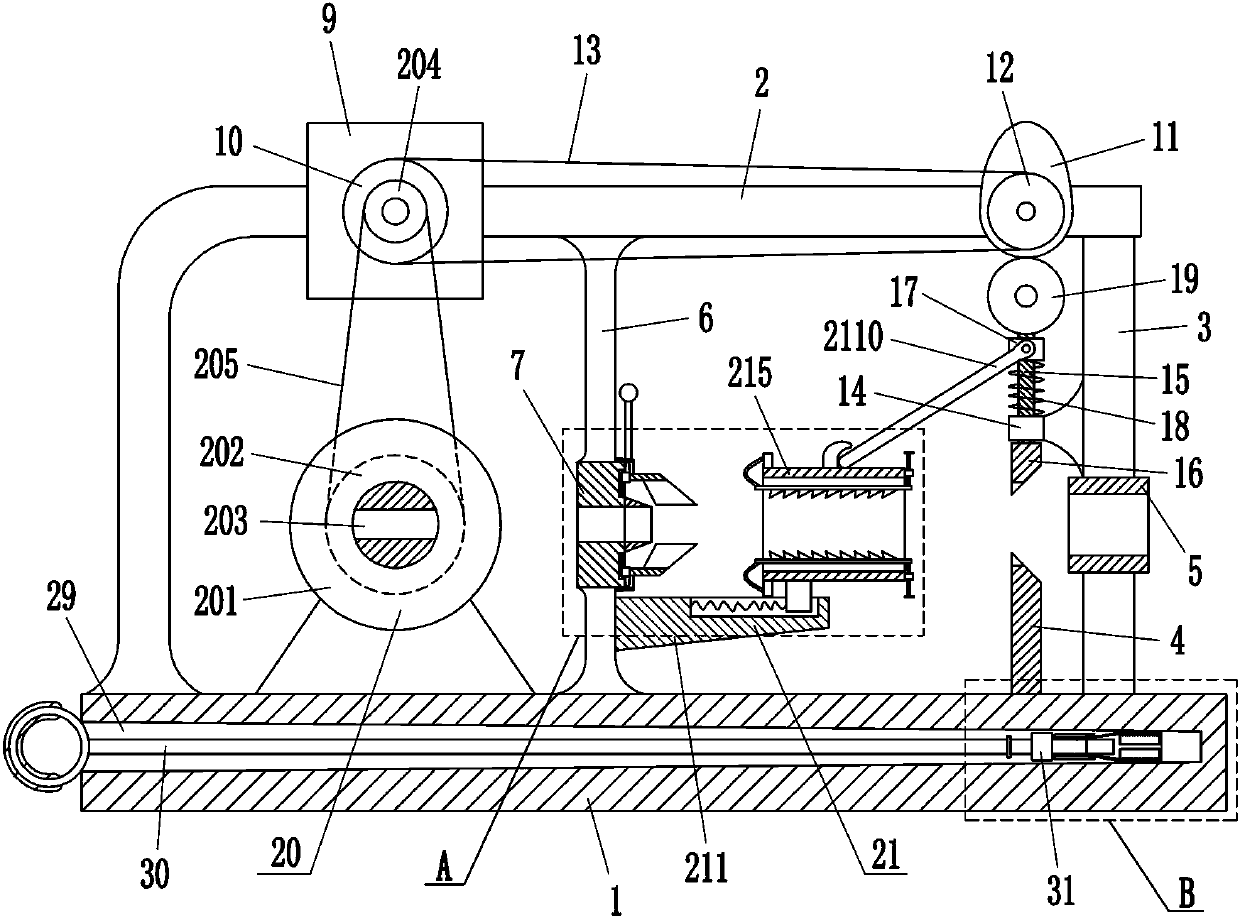

[0022] A kind of aluminum wire recycling and stripping machine, such as Figure 1-4As shown, include base 1, 7-shaped rod 2, support rod 3, fixed cutter head 4, sleeve 5, pole 6, guide sleeve 7, annular blade 8, motor 9, first pulley 10, cam 11, the first Two pulleys 12, the first flat belt 13, guide sleeve 14, guide rod 15, movable cutter head 16, limit plate 17, first spring 18, contact wheel 19 and winding mechanism 20, base 1 top left side is connected with 7 Shaped rod 2, fixed cutter head 4 and support rod 3 are fixedly connected to the top right side of base 1, fixed cutter head 4 is located on the left side of support rod 3, the top of support rod 3 is connected with the inner top of 7-shaped rod 2, and the bottom of support rod 3 is embedded There is a sleeve 5 that guides the aluminum wire, the support rod 6 is fixed in the middle of the top of the base 1, the top of the support rod 6 is connected with the inner top of the 7-shaped rod 2, and the lower part of the su...

Embodiment 2

[0024] A kind of aluminum wire recycling and stripping machine, such as Figure 1-4 As shown, include base 1, 7-shaped rod 2, support rod 3, fixed cutter head 4, sleeve 5, pole 6, guide sleeve 7, annular blade 8, motor 9, first pulley 10, cam 11, the first Two pulleys 12, the first flat belt 13, guide sleeve 14, guide rod 15, movable cutter head 16, limit plate 17, first spring 18, contact wheel 19 and winding mechanism 20, base 1 top left side is connected with 7 Shaped rod 2, fixed cutter head 4 and support rod 3 are fixedly connected to the top right side of base 1, fixed cutter head 4 is located on the left side of support rod 3, the top of support rod 3 is connected with the inner top of 7-shaped rod 2, and the bottom of support rod 3 is embedded There is a sleeve 5 that guides the aluminum wire, the support rod 6 is fixed in the middle of the top of the base 1, the top of the support rod 6 is connected with the inner top of the 7-shaped rod 2, and the lower part of the s...

Embodiment 3

[0027] A kind of aluminum wire recycling and stripping machine, such as Figure 1-4 As shown, include base 1, 7-shaped rod 2, support rod 3, fixed cutter head 4, sleeve 5, pole 6, guide sleeve 7, annular blade 8, motor 9, first pulley 10, cam 11, the first Two pulleys 12, the first flat belt 13, guide sleeve 14, guide rod 15, movable cutter head 16, limit plate 17, first spring 18, contact wheel 19 and winding mechanism 20, base 1 top left side is connected with 7 Shaped rod 2, fixed cutter head 4 and support rod 3 are fixedly connected to the top right side of base 1, fixed cutter head 4 is located on the left side of support rod 3, the top of support rod 3 is connected with the inner top of 7-shaped rod 2, and the bottom of support rod 3 is embedded There is a sleeve 5 that guides the aluminum wire, the support rod 6 is fixed in the middle of the top of the base 1, the top of the support rod 6 is connected with the inner top of the 7-shaped rod 2, and the lower part of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com