Enhancement mode flange for supporting composite insulator

A composite insulator and enhanced technology, which is applied in the field of reinforced flanges for post composite insulators, can solve the problems of difficulty in meeting the requirements of power systems, large mechanical properties and large bending resistance values, and achieve weight reduction and material costs. Effects of improving mechanical properties and controlling assembly height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

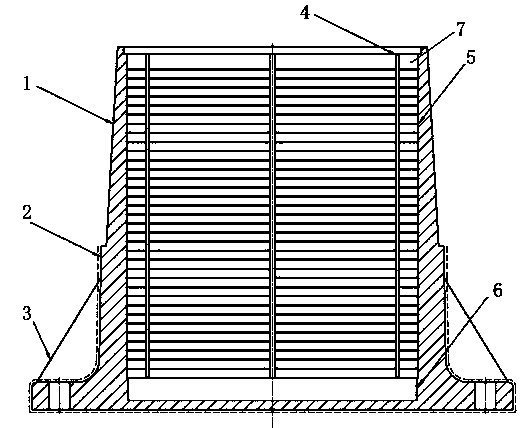

[0022] The present invention includes a conical main body 1, the inner cavity of the conical main body 1 is set, and an inner cavity positioning area 6 is arranged at the lower part of the cavity, and the inner cavity positioning area 6 is used for inserting the mandrel into the flange When guiding, the upper part of the cavity is provided with a mandrel insertion area 7 whose size is larger than that of the inner cavity positioning area 6, and the inner cavity positioning area 6 and the mandrel insertion area 7 are coaxially arranged.

[0023] Several longitudinal grooves 4 arranged vertically and several annular grooves 5 arranged circumferentially are arranged in the cavity.

[0024] The longitudinal groove 4 is longitudinally arranged along the mandrel putting area 7 , and the length of the longitudinal groove 4 is consistent with the length of the mandrel putting area 7 .

[0025] The annular grooves 5 are equidistantly distributed up and down on the mandrel insertion are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com