Precision cutting method for Teflon pipe

A Teflon tube and cutting technology, applied in metal processing and other directions, can solve the problems of slippage and deviation, difficult to guarantee cutting length and precision, and high difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

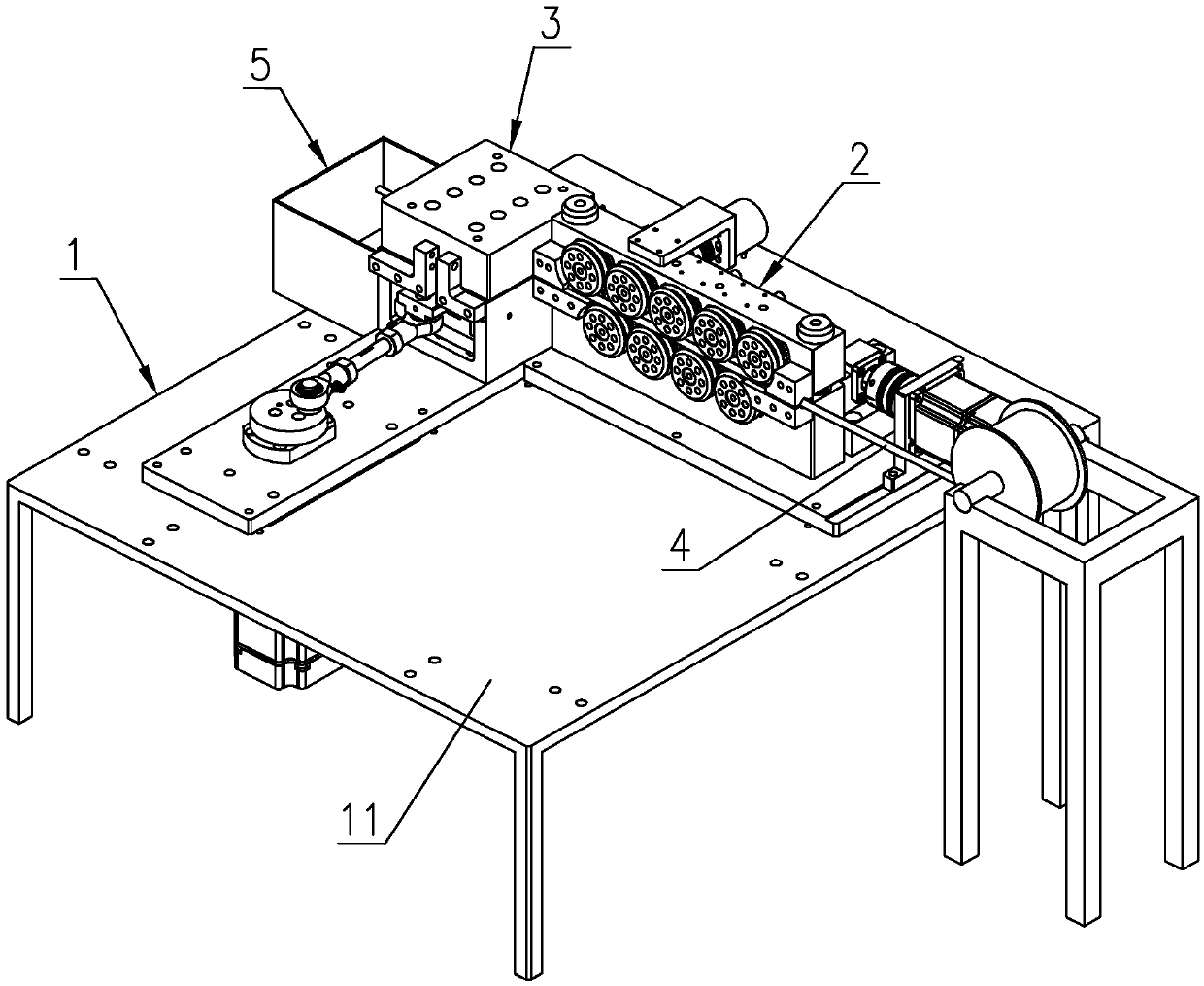

[0089] Such as Figure 1 to Figure 9 Shown, a kind of Teflon tube precision cutting equipment, it comprises frame 1, Teflon tube conveying device 2, Teflon tube cutting device 3, frame 1 is provided with frame table 11; Teflon The tube conveying device 2 and the Teflon tube cutting device 3 are fixedly installed on the rack table 11 respectively, and the Teflon tube conveying device 2 transports the fixed-length Teflon tube 4 into the Teflon tube cutting device 3 It is cut and transported to the collection box 5.

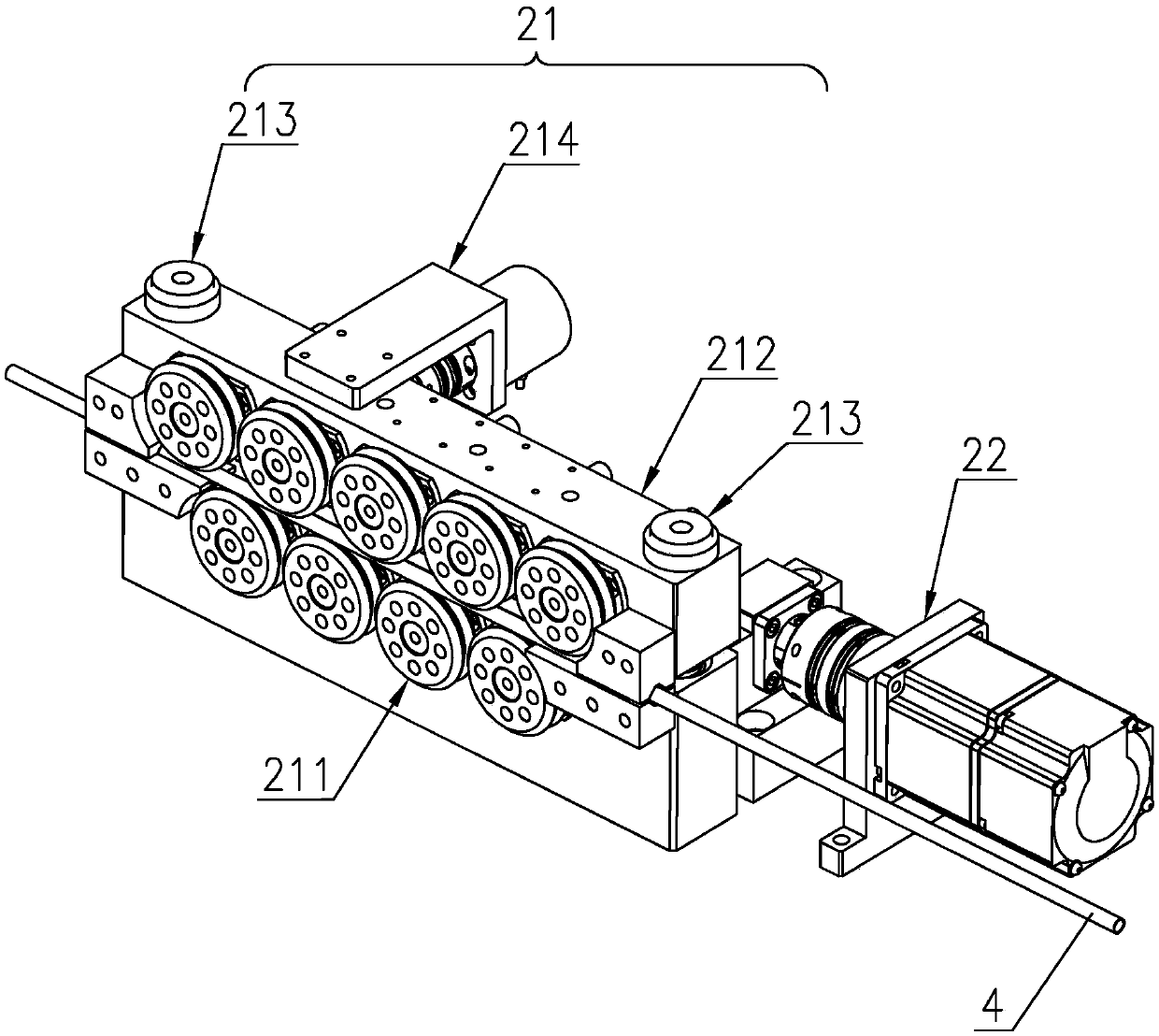

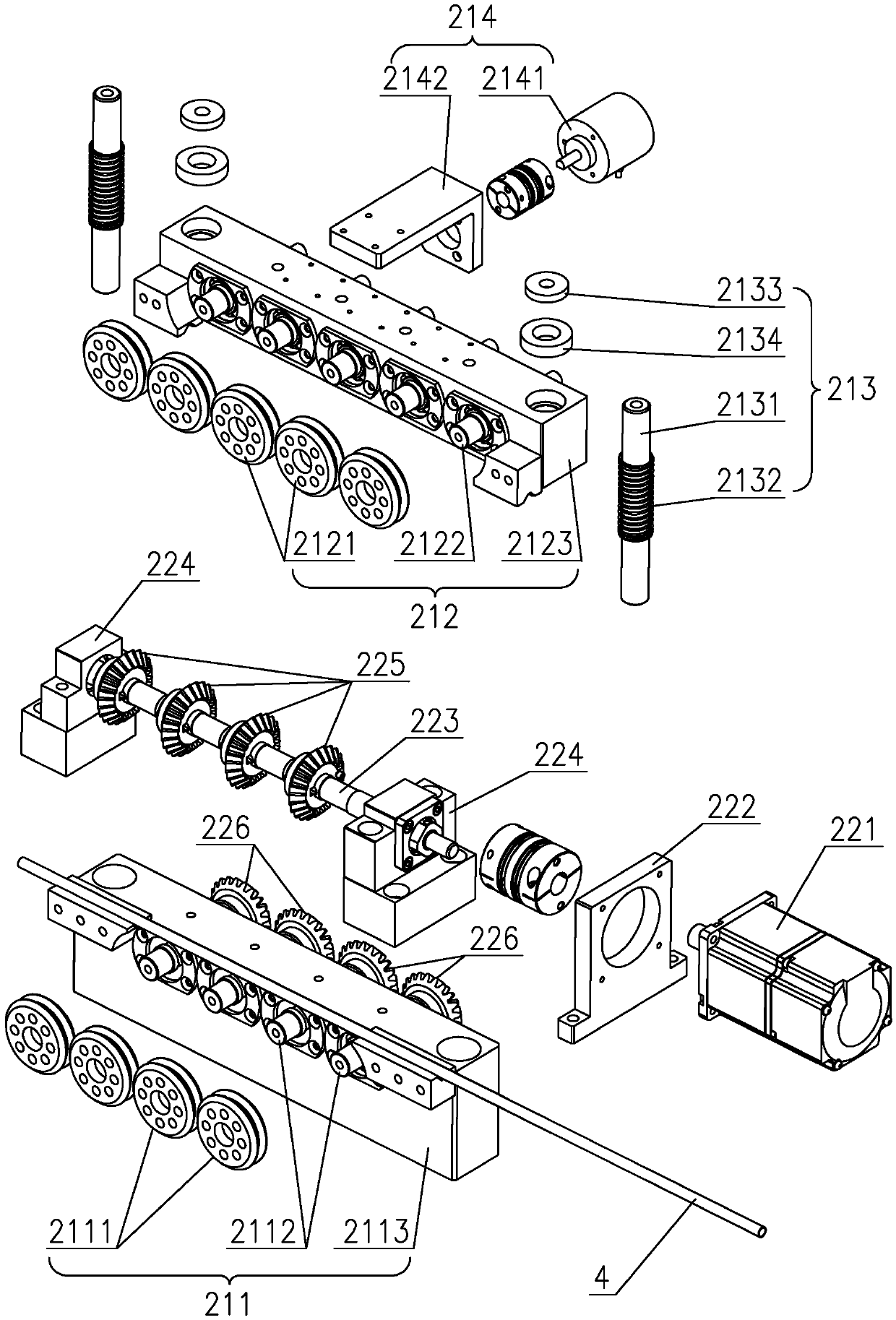

[0090] Specifically, such as Figure 1 to Figure 9 As shown, the Teflon pipe conveying device 2 includes a conveying wheel conveying mechanism 21 and a conveying wheel driving mechanism 22; Mechanism 214; driving wheel group 211 comprises 4 driving wheels 2111, 4 driving wheel shafts 2112, 1 driving wheel mounting plate 2113; passive wheel group 212 includes 5 driven wheels 2121, 5 driven wheel shafts 2122, 1 passive wheel installation Plate 2123; wheelbase adjus...

Embodiment approach 2

[0096] Embodiment 2 is basically the same as Embodiment 1, except that the driven wheel set 212 includes 4 driven wheels 2121, 4 driven wheel shafts 2122, and 1 driven wheel mounting plate 2123. The 4 driven wheel shafts 2122 are installed through the driven wheels respectively. The plate 2123 is rotatably connected with it, and the four driven wheels 2121 are fixedly installed on one end of the driven wheel shaft 2122 respectively, the driven wheel mounting plate 2123 is placed on the driving wheel mounting plate 2113, and the 4 driven wheels 2121 are directly opposite to the 4 driving wheels 2111 arrangement.

Embodiment approach 3

[0098] The third embodiment is basically the same as the first embodiment, except that the turntable 334 is replaced by a cam, and the cam is provided with a cam groove, and the pin shaft 335 is placed in the cam groove and is driven and connected by the cam groove.

[0099] Such as Figure 10 As shown, the present invention also provides a Teflon tube precision cutting method, comprising the following steps:

[0100] A. Preparation: Pull out the Teflon tube 4 from the Teflon tube turntable and insert it into the delivery wheel delivery mechanism 21;

[0101] B. Conveying: The conveying wheel driving mechanism 22 works to drive the conveying wheel conveying mechanism 21 to transport the fixed-length Teflon tube 4 forward into the clamping mechanism 31;

[0102] C. Cutting: The cutting drive mechanism 33 works to drive the cutting mechanism 32 to work and cut off the Teflon tube 4 clamped in the clamping mechanism 31;

[0103] D. Output: The conveying wheel driving mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com