Defogging rearview mirror

A rearview mirror and lens technology, which is applied in the field of rearview mirrors, can solve the problems of different cleaning levels, complex structures, and large space occupation of rearview mirrors, and achieve the effects of avoiding cleaning dead spots, clear vision, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

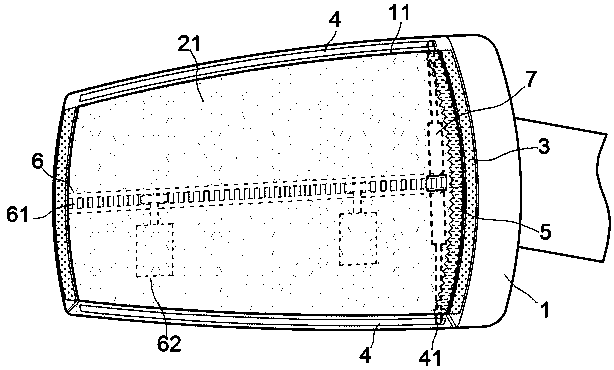

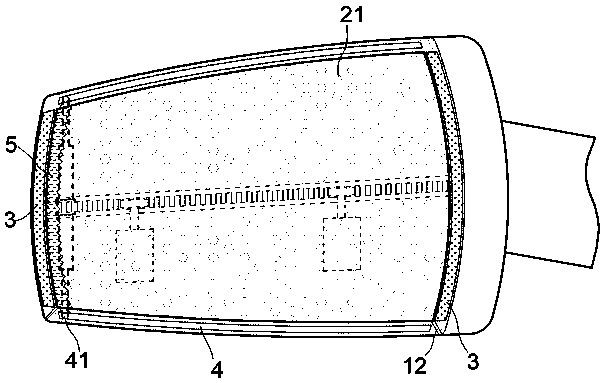

[0019] exist figure 1 , figure 2 In the shown embodiment, the defogging rearview mirror includes a hollow housing 1, a mirror groove 11 is arranged on the housing 1, and a lens is detachably installed in the mirror groove 11; There are permanent magnet patches 21 arranged in an equidistant array on the back side of the mirror groove 11, and shaping strips 3 are arranged on the left and right side walls of the mirror groove 11, and the shaping strips 3 are made of permanent magnetic materials;

[0020] The upper edge and the lower edge of the mirror groove 11 are provided with a guide chute 4, and a traction post 41 is slidably arranged in the two guide chute 4, and an elastic material is installed between the two traction posts 41 to make The cleaning strip 5, the cleaning strip 5 includes a transparent tube made of elastic material, filled with transparent colloid in the transparent tube, mixed with ferromagnetic powder and suspended colored beads in the colloid; under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com