Mobile nozzle plane cleaning device and self-cleaning maintenance-free electrostatic purification system

A cleaning device and purification system technology, applied in electrostatic separation, electrode cleaning, etc., can solve the problems of high labor maintenance cost, low work efficiency, long maintenance time, etc., to avoid secondary dust, reduce cleaning cost, and improve cleaning effect. and efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0121] Example 1 Moving Nozzle Plane Cleaning Device—Cleaning Nozzles

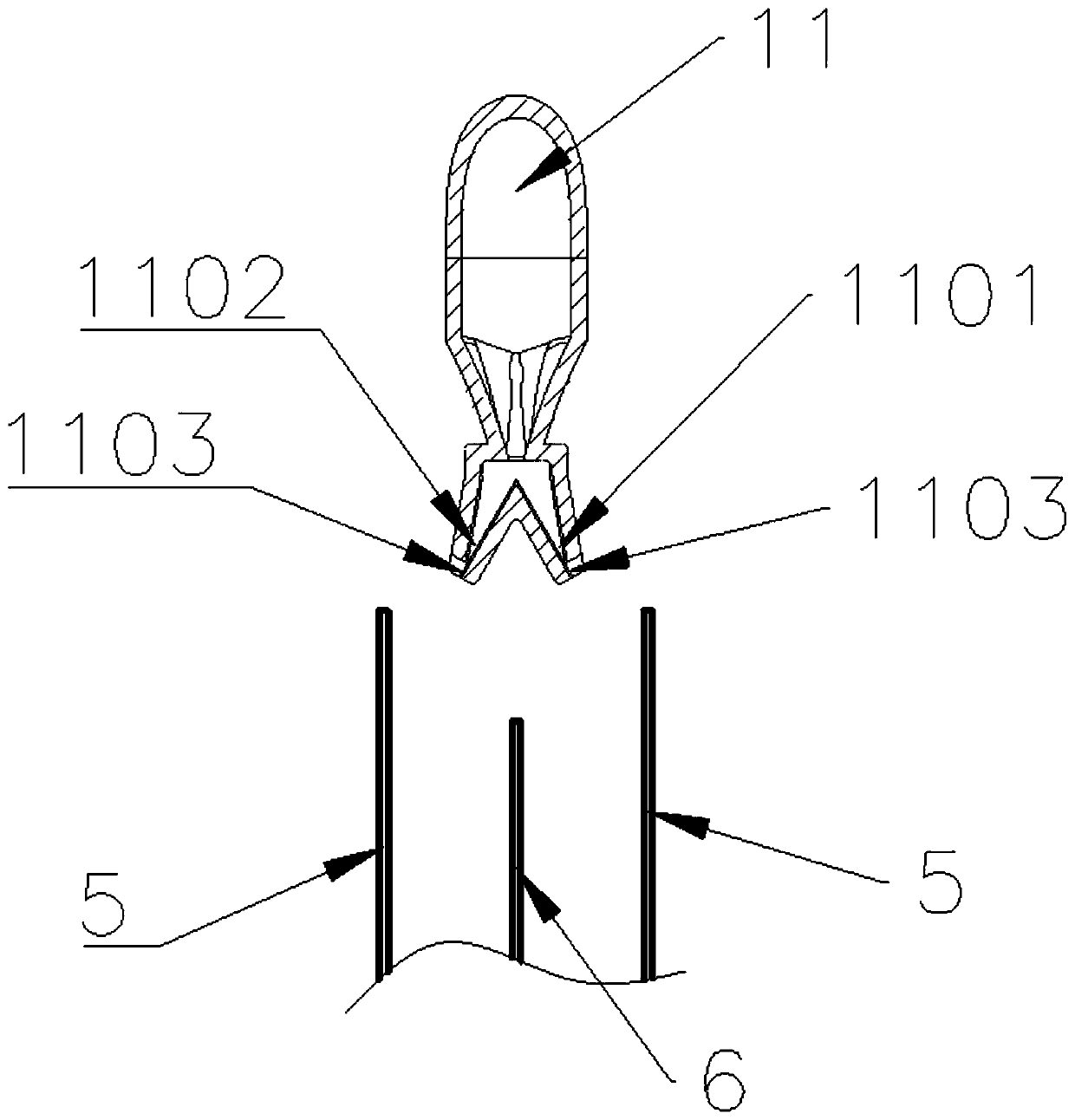

[0122] In a specific embodiment of the present application, the structure of the nozzle 11 is shown in figure 1, the lowest point of the nozzle 11 is higher than the highest point of the dust collecting plate 5 and the ionization plate 6 . The nozzle 11 includes a liquid outlet 1101 , a liquid outlet 1102 and a flow guiding part 1103 , all of which are located outside the gap between the dust collecting plate 5 and the ionizing plate 6 . The opening cross-sectional area of the liquid outlet 1101 and the liquid outlet 1102 and the angle of the guide part 1103 are designed and calculated. In this embodiment, the distance d between the dust collecting plate 5 and the ionizing plate 6 is ≥ 5mm, and the liquid outlet The opening slit width dimension σ of the port 1101 and the liquid outlet 1102 satisfies 0.1mm≤σ≤2mm, the guide part 1103 is an inverted V-shaped structure, and the angle λ between the guide par...

Embodiment 2

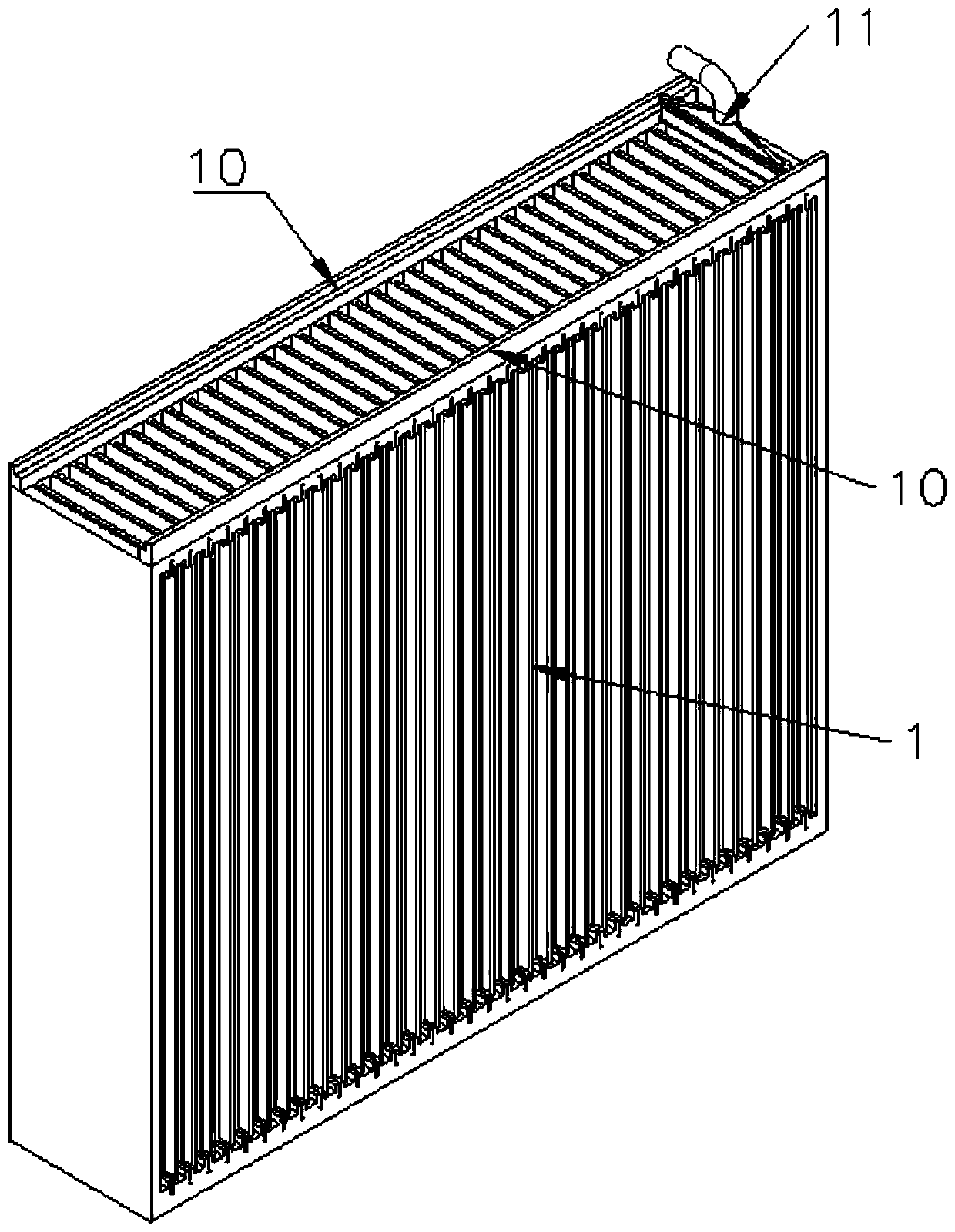

[0125] Embodiment 2 Moving Nozzle Plane Cleaning Device

[0126] In a specific embodiment of the present application, the structural diagram of the moving nozzle plane cleaning device is shown in figure 2 , the mobile nozzle plane cleaning device of this embodiment is located at figure 2 Above the dust collection section 1 of the medium and high voltage electrostatic purification system, the moving nozzle plane cleaning device includes a slide rail 10 and the nozzle 11 in the first embodiment. The nozzle 11 is arranged on the upper end of the dust collection section 1, and under the action of the external drive device, the nozzle 11 can complete the displacement track along the slide rail 10 according to the program setting, that is, it moves above the gap of a dust collection plate, stops and sprays. liquid cleaning. The pulse jet cleaning method is adopted, the pulse jet pressure is 1Mpa, and the pulse jet frequency is 2 times / min. After the cleaning is completed, move ...

Embodiment 3

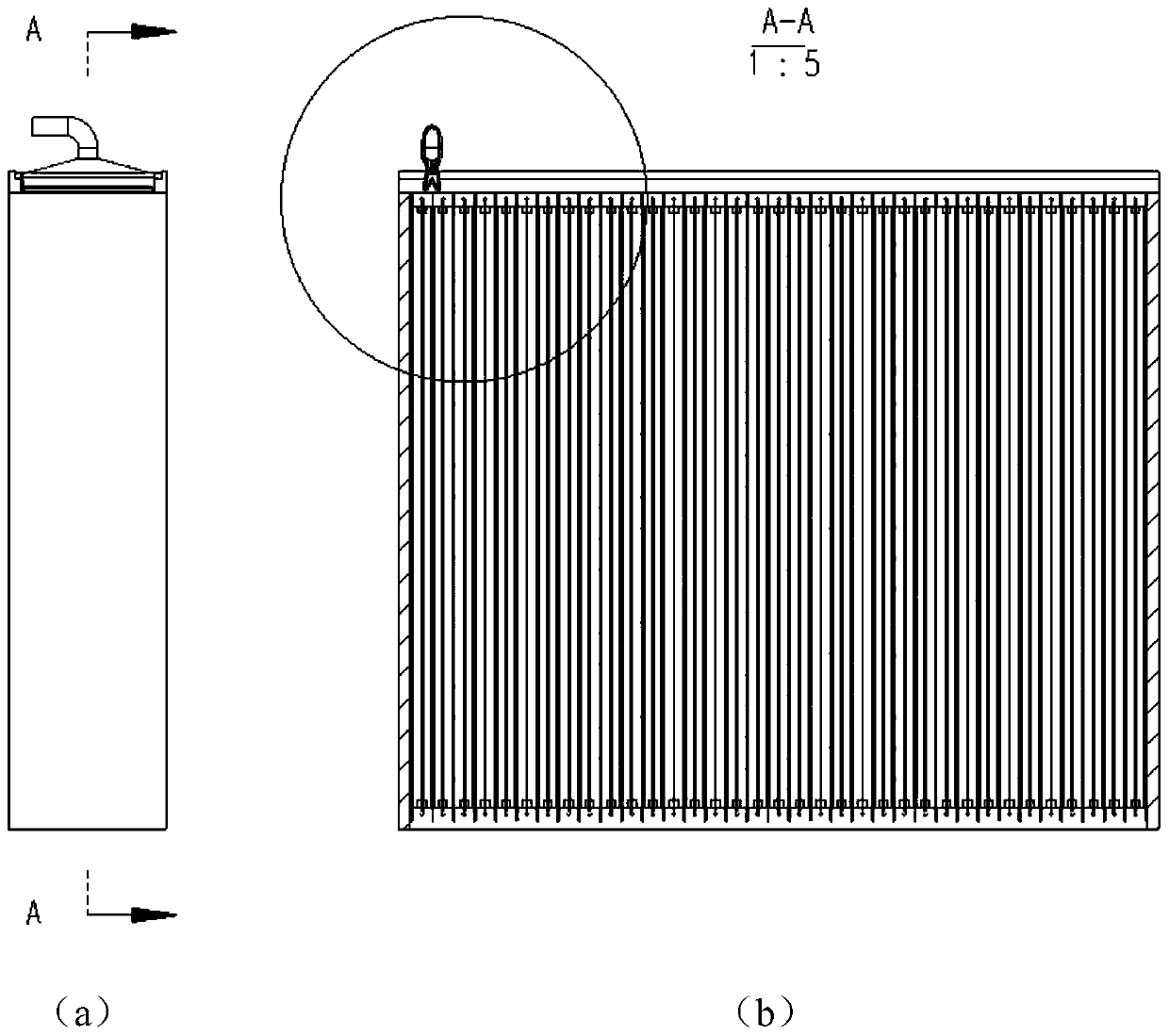

[0129] Example 3 Mobile Nozzle Plane Cleaning Device—Single-side Liquid Outlet Nozzle

[0130] Similar to the nozzle structure of embodiment 1, the difference is that the nozzle of this embodiment is a single-sided liquid outlet, please refer to Figure 7 Side view of the single-sided outlet nozzle. For the front view of the single-side liquid outlet nozzle in this embodiment, please refer to Figure 8 (b), the side view sectional view of its A-A direction is Figure 8 (a).

[0131] In a specific embodiment, in the mobile nozzle plane cleaning device, two single-side liquid outlet nozzles of this embodiment are arranged between every two adjacent dust collecting plates 5, and the liquid outlets of the two nozzles are respectively directed toward the two sides. Side dust collecting plate 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com