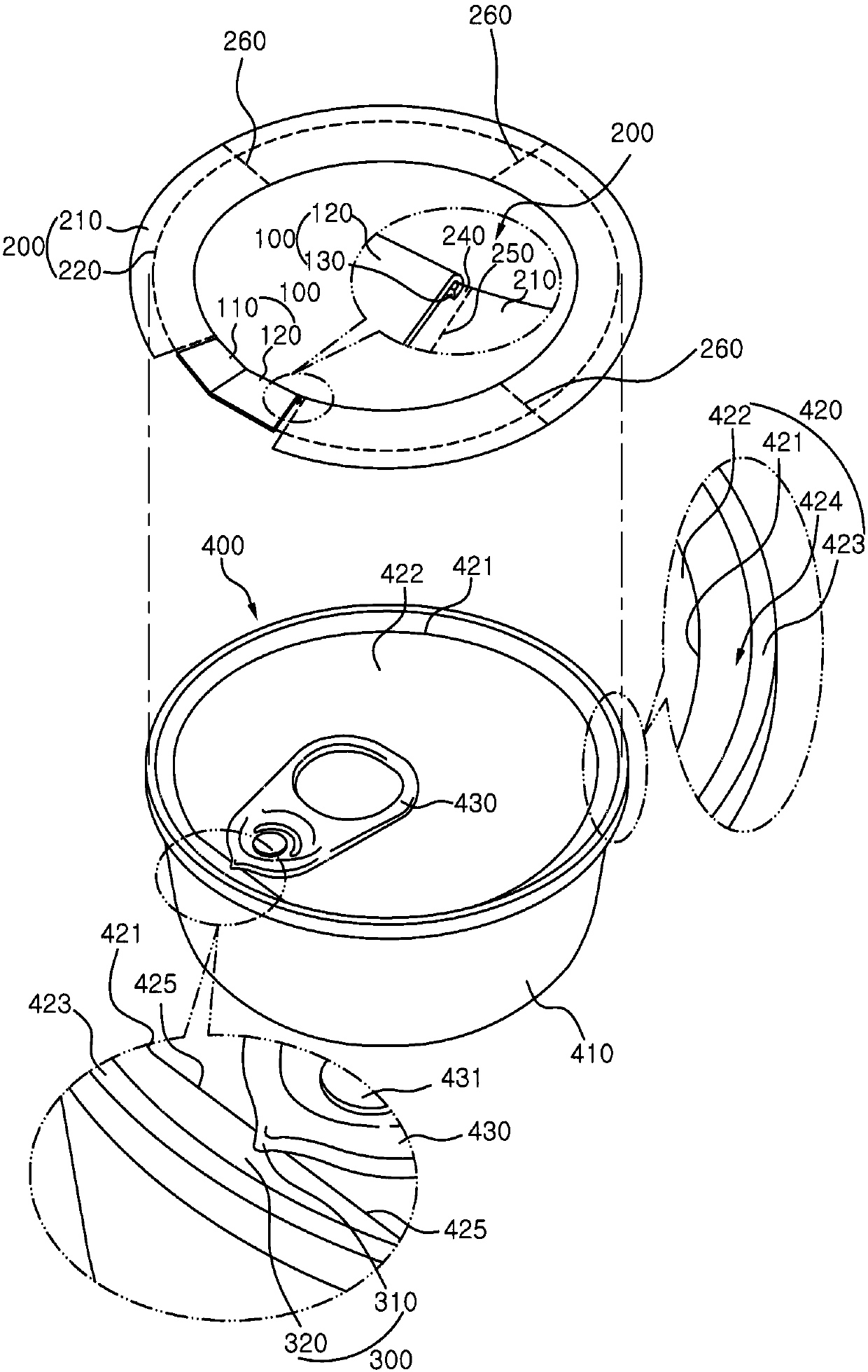

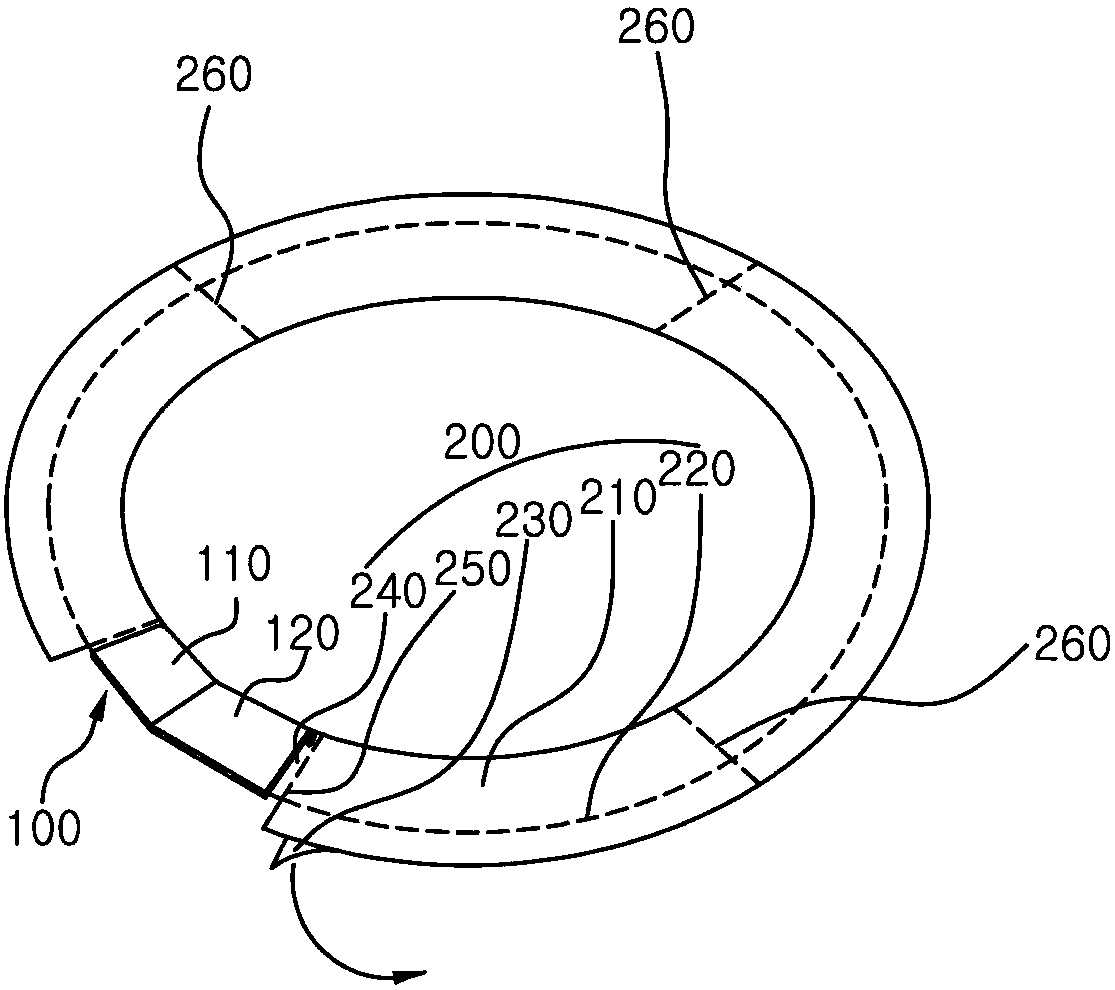

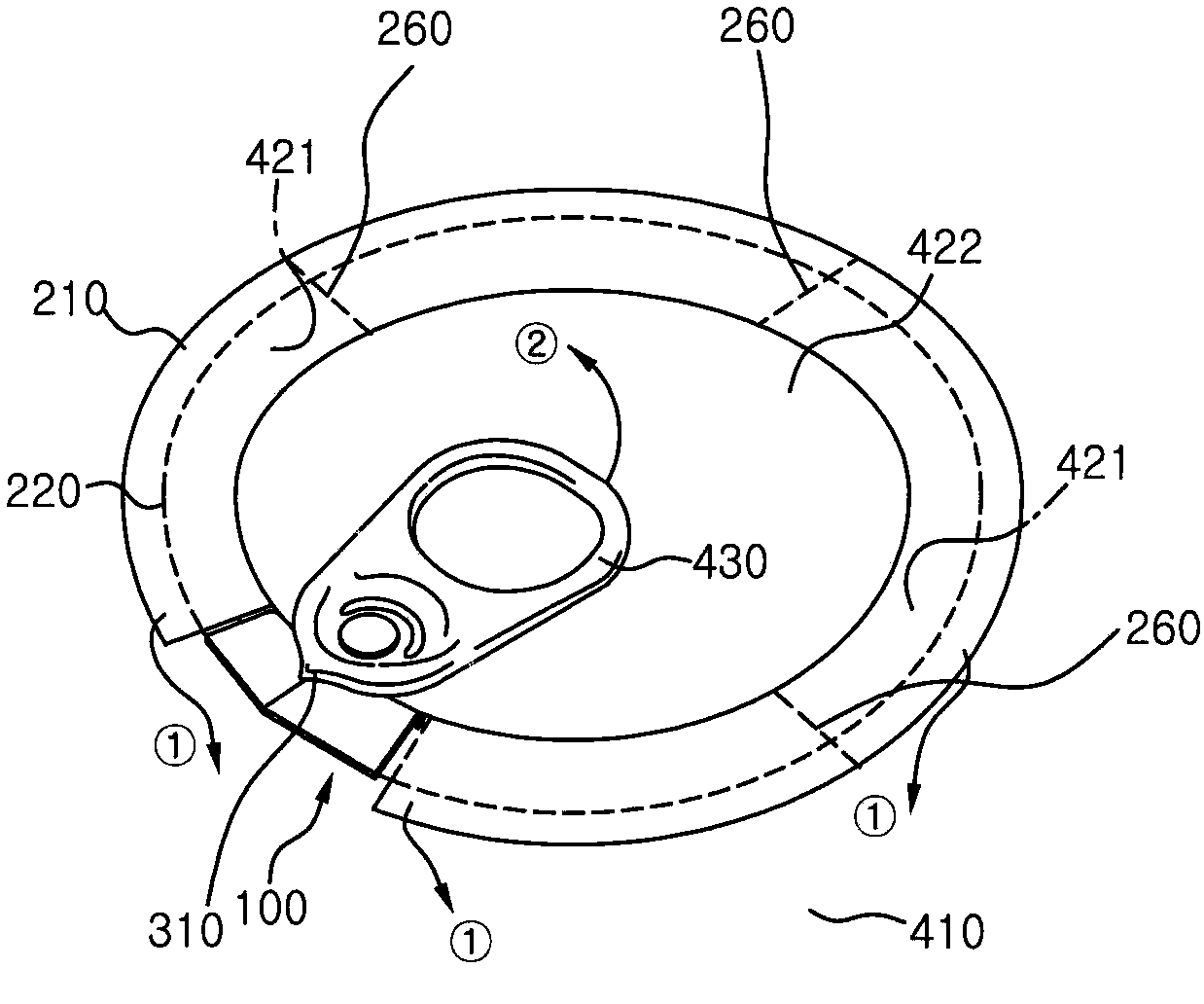

Zip-top can assembly with injury preventing function

A technology of cans and components, which is applied in the field of cans with anti-injury functions, can solve the problems of cutting fingers on the edge of the upper cover, expanding additional projects, and low economic efficiency, and achieves the effects of eliminating waste, reducing production costs, and reducing components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The advantages, features and methods for achieving the objects of the present invention can be more easily understood by referring to the accompanying drawings and the embodiments described in detail below.

[0059] But the present invention is not limited to the embodiments described below, and it can be implemented in many different ways.

[0060] The embodiments described below are provided only to make the present invention more complete and to fully introduce the scope of claims of the present invention to those skilled in the art.

[0061] In addition, the present invention is defined only by the scope of the claims.

[0062] Therefore, to avoid obscuring explanations of well-known structural elements, acts, and techniques in several embodiments, specific descriptions thereof are not given.

[0063] In addition, the same reference numerals used in this specification refer to the same structural elements, and the terms used (related to) in this specification are use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com