An extrusion device for producing aluminum composite panels

An extrusion device and aluminum composite panel technology, applied in the field of extrusion devices, can solve the problems of high scrap rate, increased production cost, discharge, etc., and achieve the effects of simple results, convenient implementation, and prevention of solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

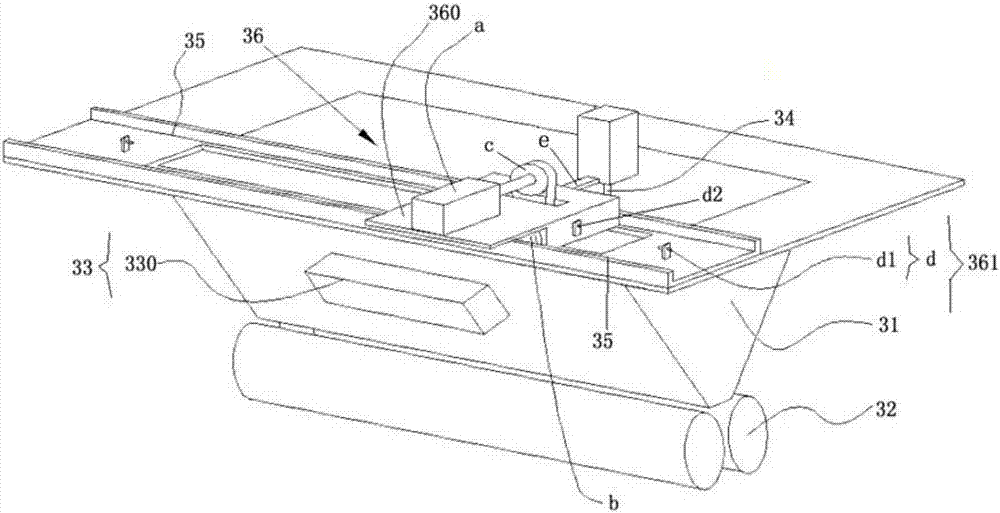

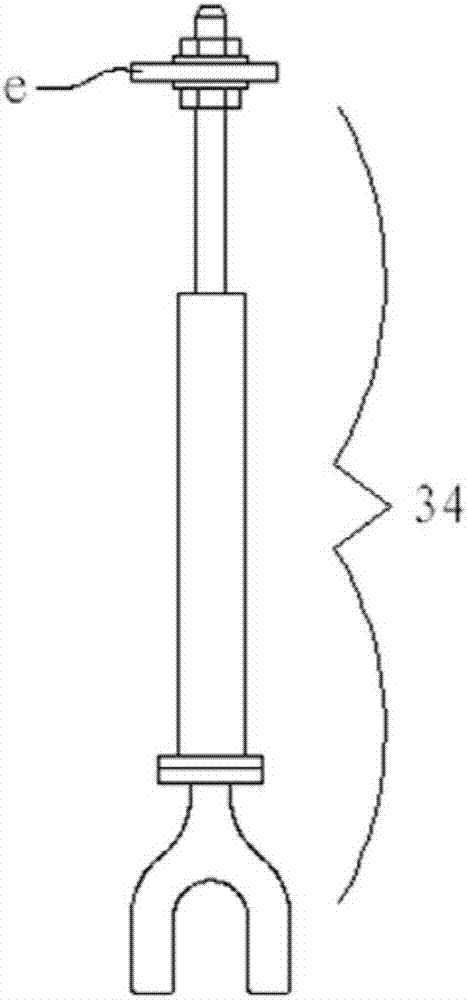

[0026] Such as figure 1 As shown, the extrusion device used in the production of aluminum composite panels provided in this embodiment includes a silo 31, an extrusion roller 32 installed at the discharge port of the silo 31, and a roller set on the outer peripheral side wall of the silo 31. The vibrating mechanism 33 , the vibrating bar 34 used to vibrate the material in the silo 31 and shake out the air bubbles in the material, and the pushing mechanism 36 used to push the vibrating bar 34 to move in the silo 31 .

[0027] Specifically, the longitudinal section of the bin 31 is a trapezoid whose outer diameter gradually decreases from top to bottom, and the outlet is located at the bottom of the trapezoid, and the outlet extends along the length of the bin 31 . It is convenient for unloading of materials.

[0028] The extrusion roller 32 ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com