Return type round tube belt conveyor

A round tube belt and conveyor technology, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problems of strict requirements for materials, small conveying volume, unstable overall operation, etc., to achieve low running resistance, The effect of low operating power and reduced cleaning and maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

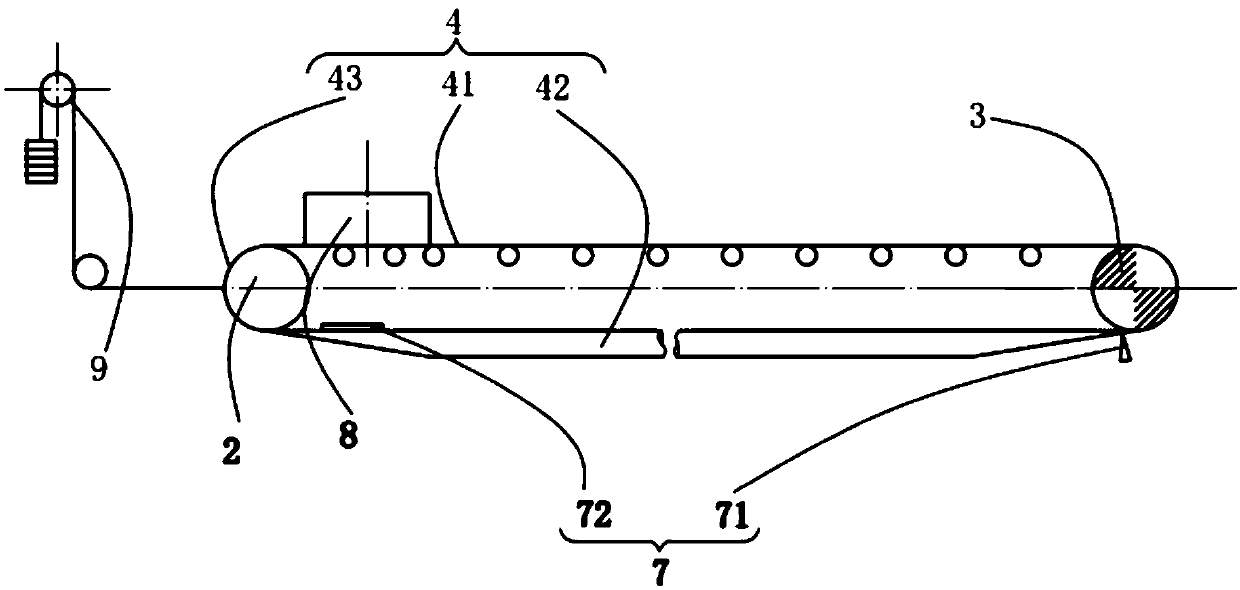

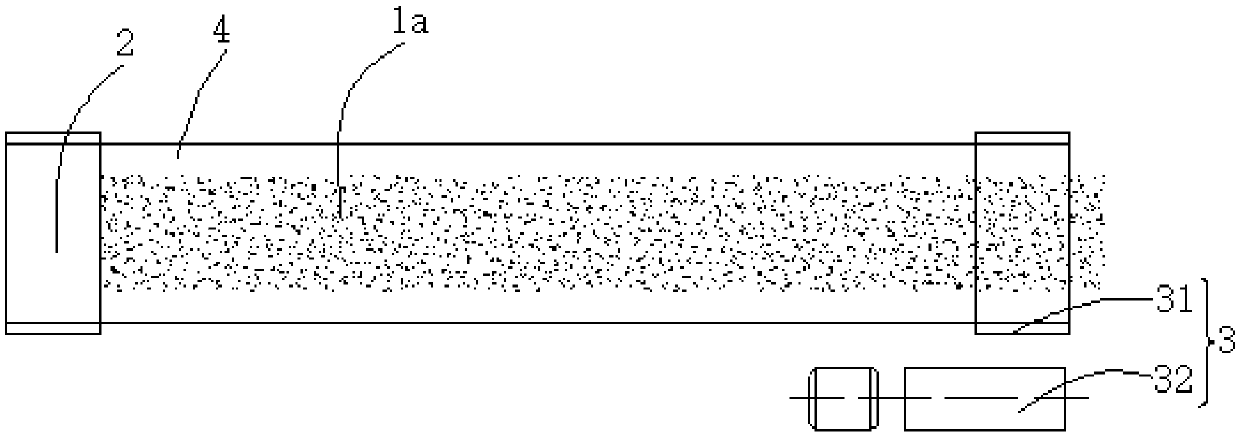

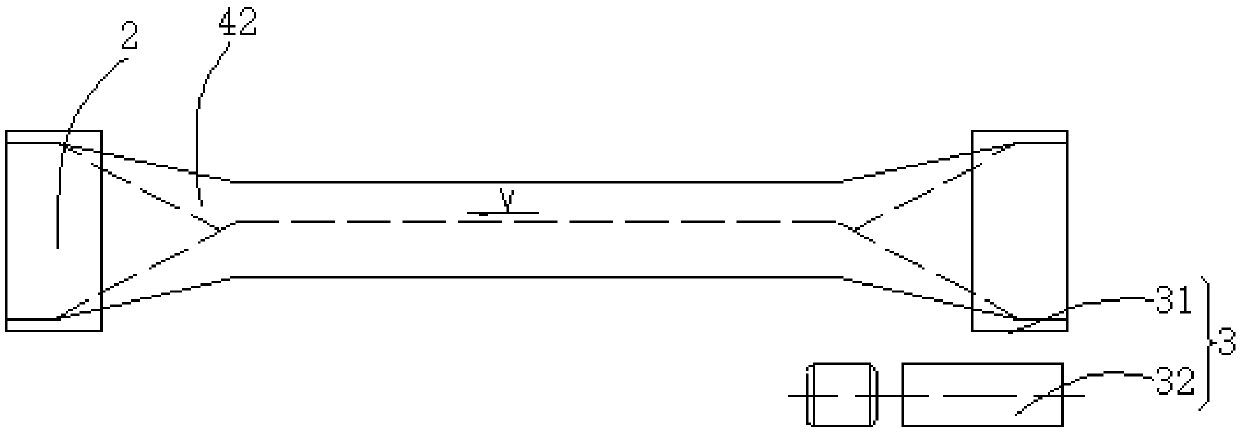

[0029] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 ,in, figure 1 A schematic structural view of a preferred embodiment of the return-type circular tube belt conveyor provided by the present invention; figure 2 for figure 1 A top view of the conveyor belt structure shown; image 3 It is the bottom view of the second conveyor belt of the present invention; Figure 4 for figure 1 The side view of the overall structure shown; Figure 5 for figure 1 Schematic diagram of the local three-dimensional structure of the structure shown. The return round pipe belt conveyor includes: a transmission frame 1, a first roller 2, a second roller 3 and a conveyor belt 4, the first roller 2 and the second roller 3 are respectively located at the ends of the transmission frame 1 two ends, and the first roller 2 and the second rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com