Deviation-rectifying feeding device of ultrasonic self-deviation-rectifying slitter

A self-correcting and strip cutting machine technology, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of easy deviation of coils and low efficiency of strip cutting, and achieve saving configuration, simple adjustment, The effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

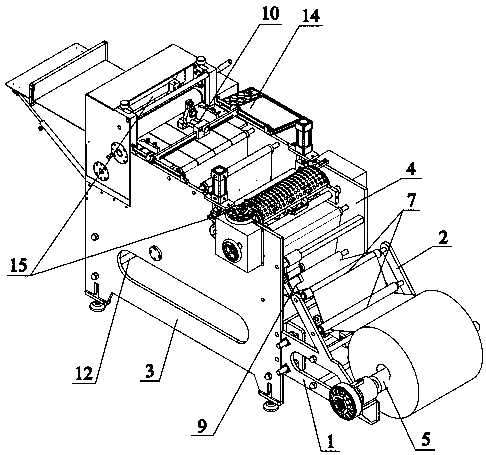

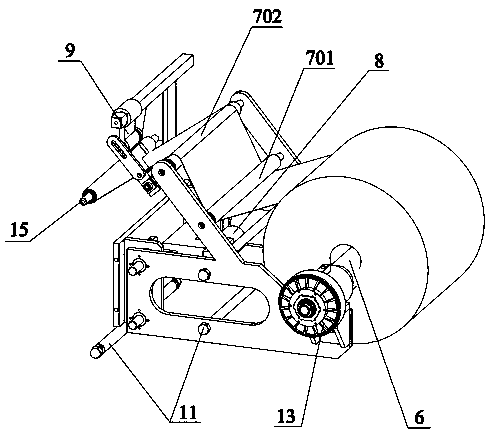

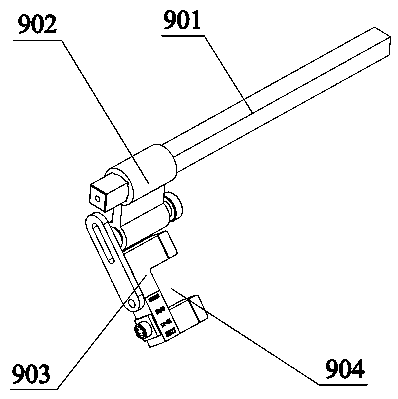

[0023] An ultrasonic self-correcting deviation-correcting feeding device for a strip cutting machine, comprising a frame composed of a left deviation-correcting plate 1, a right deviation-correcting plate 2, a left wallboard 3 and a right wallboard 4, and the outside of the right wallboard 4 is provided with a control The control box 14 of the operation of the deviation correction feeding device 5; the deviation correction feeding device 5 is arranged between the left deviation correction plate 1 and the right deviation correction plate 2, and the strip cutting device 15 is arranged at the rear of the deviation correction feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com