Yarn padding tank capable of saving impregnation liquid and realizing uniform dyeing and working method of yarn padding tank

A working method and dipping liquid technology, which is applied in liquid/gas/steam yarn/filament processing, textile processing machine accessories, textile material processing, etc. It can solve the problems of dripping liquid polluting the working environment, excessive use of dipping liquid, and yarn Uneven thread impregnation and other problems, to achieve the effect of saving recycling, saving water consumption, and uniform dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

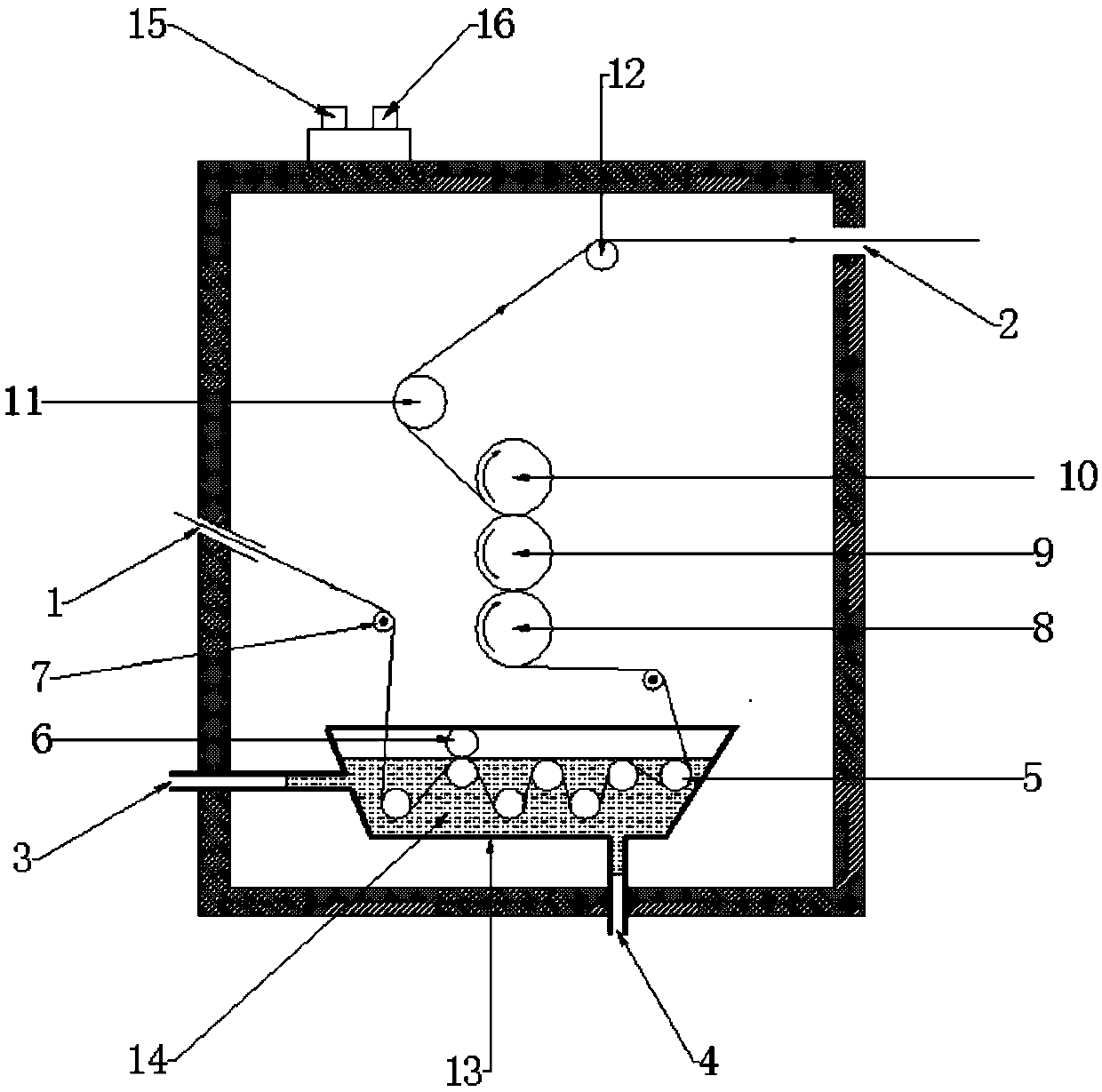

[0024] like figure 1 A dipping tank for saving dipping liquid and uniformly dyed yarn is shown, comprising: yarn inlet 1, yarn outlet 2, guide roller 7, first roll 8, first tension roller 11, second Tension roller 12, impregnation unit 14, first switch 15, second switch 16; a guide roller 7 is arranged below one side of the yarn inlet 1; a padding unit 14 is arranged below the guide roller 7 The top of the padding unit 14 is provided with a first roll 8, the top of the first roll 8 is provided with a first tension roll 11; the top of the first tension roll 11 is provided with a second tension roll 12. One side of the second tension roller 12 is provided with a yarn outlet 2, the first switch 15 is located on the outer box wall of the padding device, and the second switch 16 is located on the outer box wall of the padding device.

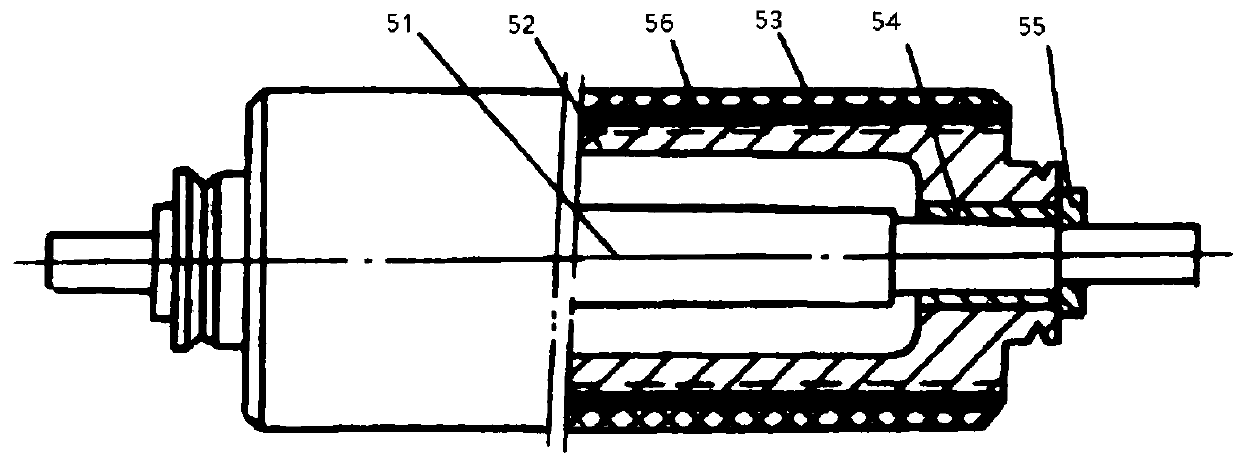

[0025] The dipping unit 14 described in the present embodiment comprises a dipping tank 13, a dipping roll 5, a pressing roll 6, a material inlet 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com