Fabricated two-stage retaining wall structure

A retaining wall and prefabricated technology, applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve the problem of large space occupied by sidewalks behind walls, small space occupied by sidewalks, and hard structures of retaining walls Excessive exposure and other problems, to achieve the effect of maintaining overall structural stability and thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

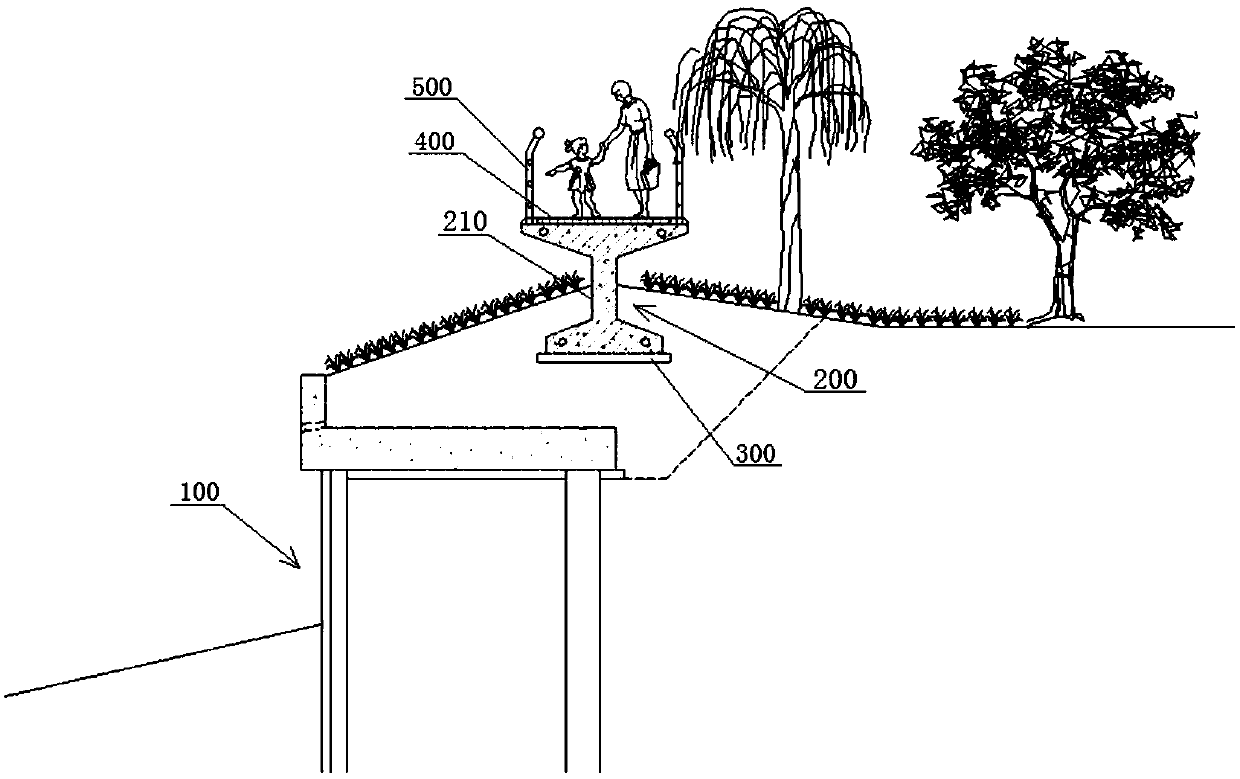

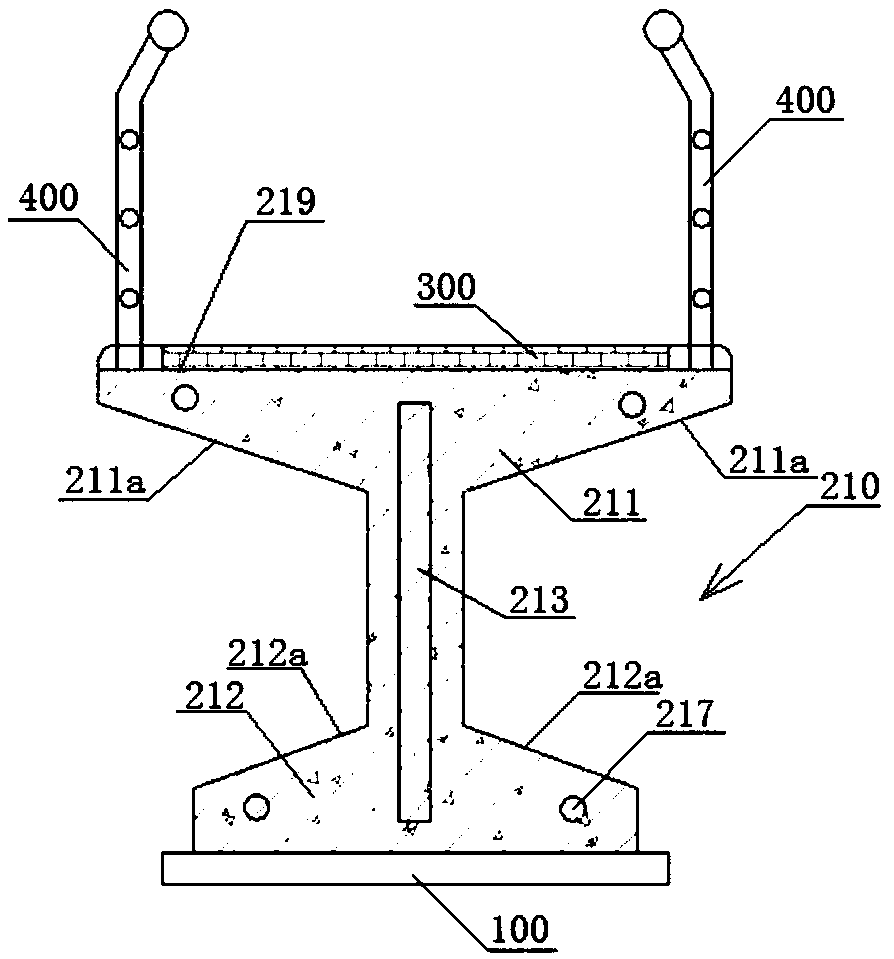

[0034] see figure 1 , shown in the figure is a prefabricated two-stage retaining wall structure, which is set in the revetment section of the river course with high landscape requirements, including the first-level retaining wall 100 set at the river bank and the first-level retaining wall set at the river bank and located at the first level The secondary retaining wall 200 above the retaining wall 100 . The bottom of the secondary retaining wall 200 is provided with a wall cushion 300, and the wall cushion 300 is preferably a plain concrete cushion with a thickness of 100 mm to 200 mm.

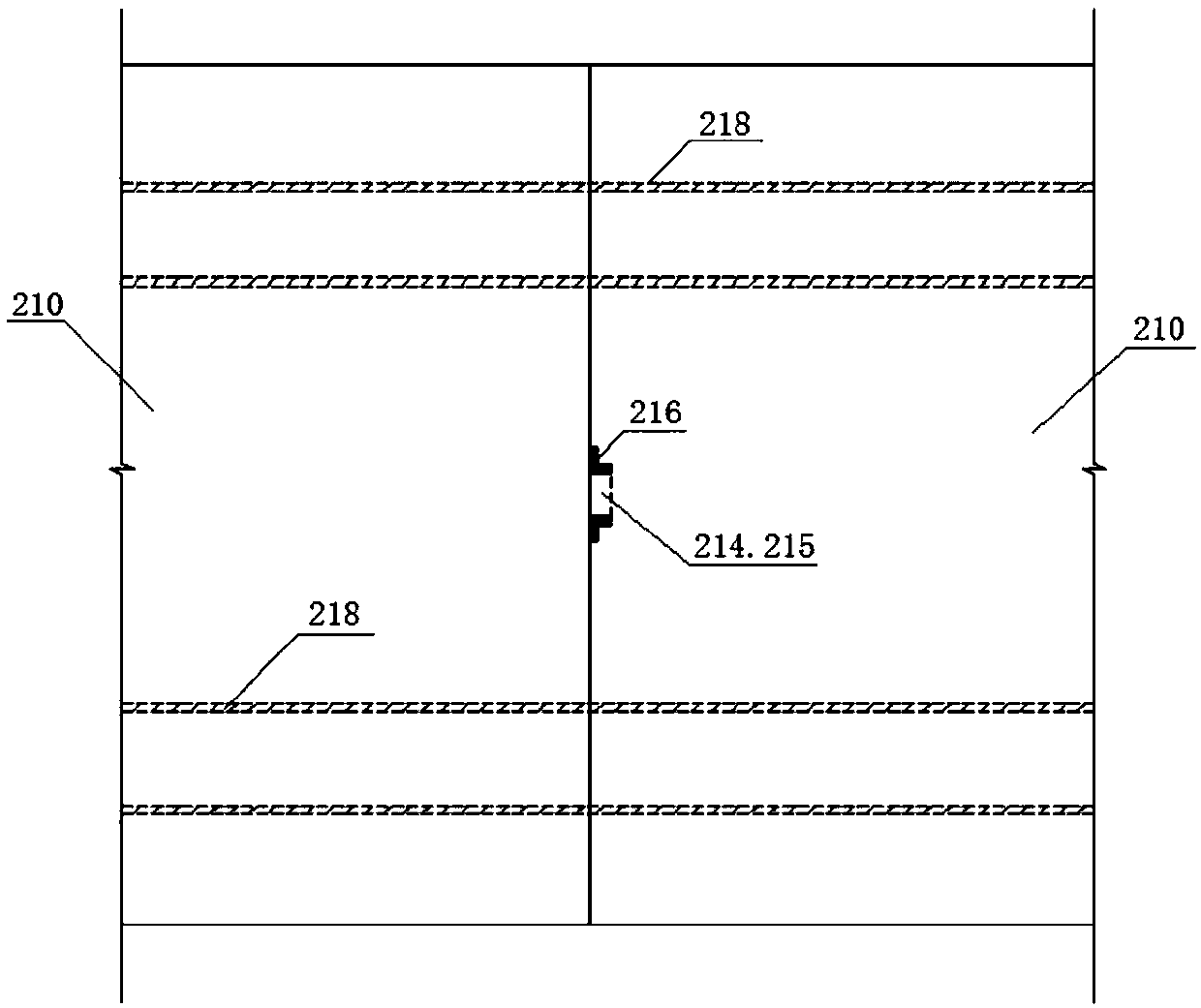

[0035] The secondary retaining wall 200 is assembled by several sections of solid wall units 210 along the extension direction of the river bank, and a walkway 400 is built on the top surface of the assembled sections of solid wall units 210, which reduces the slope of the traditional walkway. Occupation, make full use of the river bank space, better river landscape, but also save the overal...

Embodiment 2

[0044] The structure of this embodiment is roughly the same as that of Embodiment 1, the difference is: see Figure 7 , the solid wall body unit is an inverted T-shaped wall body unit 210', and the inverted T-shaped wall body unit 210' includes a retaining wall bottom plate 211' and a retaining wall body 212', and the retaining wall wall body 212' is vertically arranged on the retaining wall bottom plate 211 ′, on both sides of the retaining wall body 212 ′ on the retaining wall bottom plate 211 ′, a plurality of retaining wall body vertical supports 213 ′ are arranged at intervals along the length direction of the retaining wall bottom plate 211 ′. Wherein, the thickness of the retaining wall bottom plate 211' is 500mm-800mm, the thickness of the retaining wall body 212' is 500mm-800mm, and its height is 1200mm-3000mm. The retaining wall bottom plate 211', the retaining wall body 212' and the retaining wall wall vertical support 213' are integrally formed by concrete prefabri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com