High-rise trackless lifting garage with cantilever beams

A technology for elevating trailers and high-rises, applied in the field of mechanical three-dimensional parking equipment, can solve the problems of occupation, unfavorable promotion and popularization, and high cost, and achieve the effect of rapid vehicle placement, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

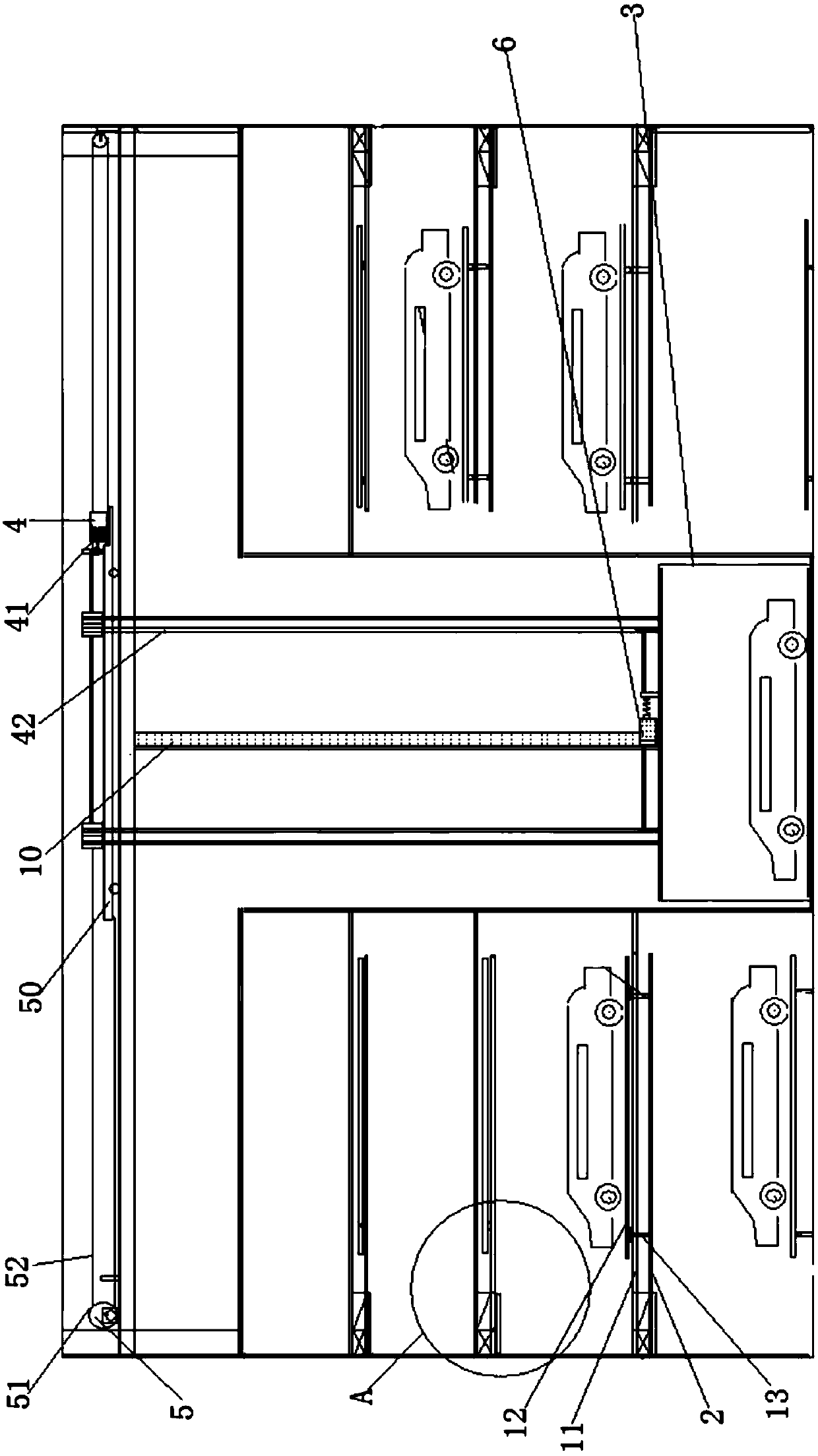

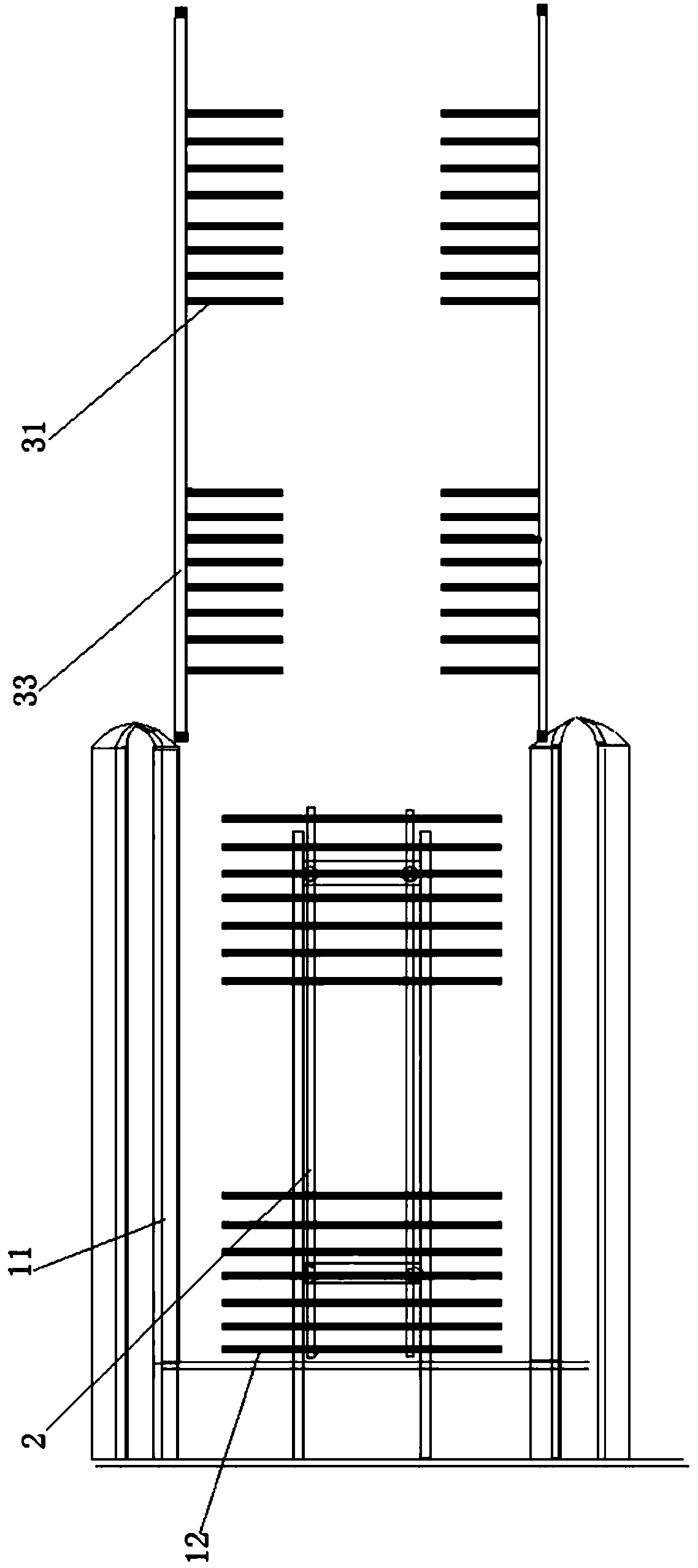

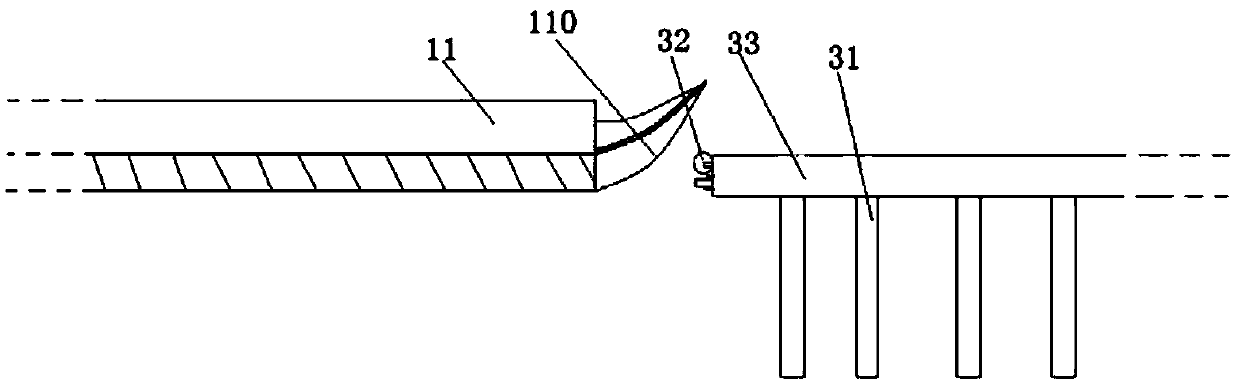

[0030] Such as Figure 1-11 As shown, a high-rise trackless beam-lifting garage includes a frame 1, a carriage 3, a first driving device 4 and a second driving device 5, the frame 1 is a steel metal frame, and the frame 1 directly stands on the ground; A plurality of cantilever beams 2 are arranged on the frame 1, the cantilever beams 2 are steel bars, one end of the cantilever beams 2 is connected to the frame 1, and the other end is suspended; above the cantilever beams 2 Establish comb rack 12, this comb rack 12 is a plurality of metal combs to form a shelf, and described comb rack 12 is connected with described pick beam 2 by jack 13, and described jack 13 can promote described comb rack 12 Upward movement; two compartment guide rails 11 are arranged on the frame 1, the two compartment guide rails 11 are symmetrically arranged, the compartment guide rails 11 are metal rails, and one end of the compartment guide rails 11 is connected to the frame 1 Therefore, when the firs...

Embodiment 2

[0043] Such as Figure 11 As shown, the difference between this implementation and Embodiment 1 is that this embodiment is a one-sided single entrance, and the number of layers for placing vehicle comb racks is M layers, and M≥3, and each layer has N rows of comb racks and N≥2, so the total number of vehicles that can be placed in the garage is M×N-1; at the same time, a layer of one-sided protective platform 7 is provided on the frame, and the single-sided protective platform 7 is composed of multiple angle steel connections .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com