Horizontal adjusting tool and calibration method in mounting of inertial navigation device during ship inclination

A level adjustment and tooling technology, applied in the direction of measuring devices and instruments, can solve the problems that the control of the ship’s horizontal attitude is difficult to meet the technical requirements, the calibration process cannot carry out the installation and calibration work, and the high precision control requirements of the testing instruments are achieved. Achieve level detection and calibration, meet the requirements of different erection heights, and achieve the effect of simple level adjustment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

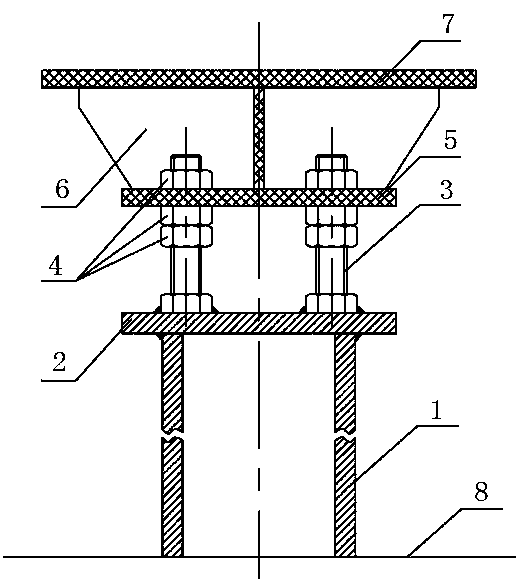

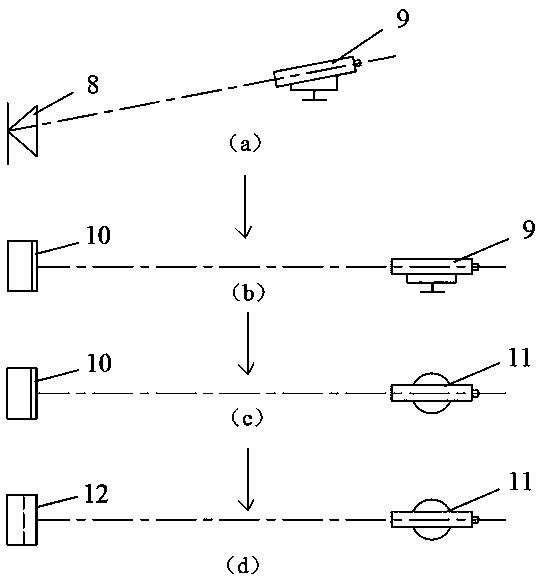

[0025] Such as figure 1 and figure 2 As shown, the horizontal adjustment tooling of this embodiment includes a pillar 1, a support panel 2, a bolt 3, a nut 4, a bottom plate 5, a toggle plate 6 and an instrument installation panel 7, and the pillar 1 is arranged on a ship deck 8, The pillar 1, the support panel 2 and the bolt 3 are welded to form an assembly support base, the bottom plate 5, the toggle plate 6 and the instrument installation panel 7 are welded to form an assembly instrument erection installation adjustment base, and the assembly support base and the assembly The installation and adjustment base of the instrument is fixed by the nuts 4, and the nuts 4 are respectively threaded on the bolts 3, and the nuts 4 are respectively located on the upper surface of the bottom plate 5 and between the support panel 2 and the bottom plate 5. By adjusting the nuts under the bottom plate, the instrument and the calibration equipment can be adjusted to the same height simply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com