Multichannel high-speed rail overhead line system dropper fatigue test device

A fatigue test, multi-channel technology, applied in the field of catenary hanging string fatigue test method and device, can solve the problems of difficulty in implementation, inability to complete the test, low efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The hanging string fatigue test device provided by the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, which are explanations of the present invention rather than limitations.

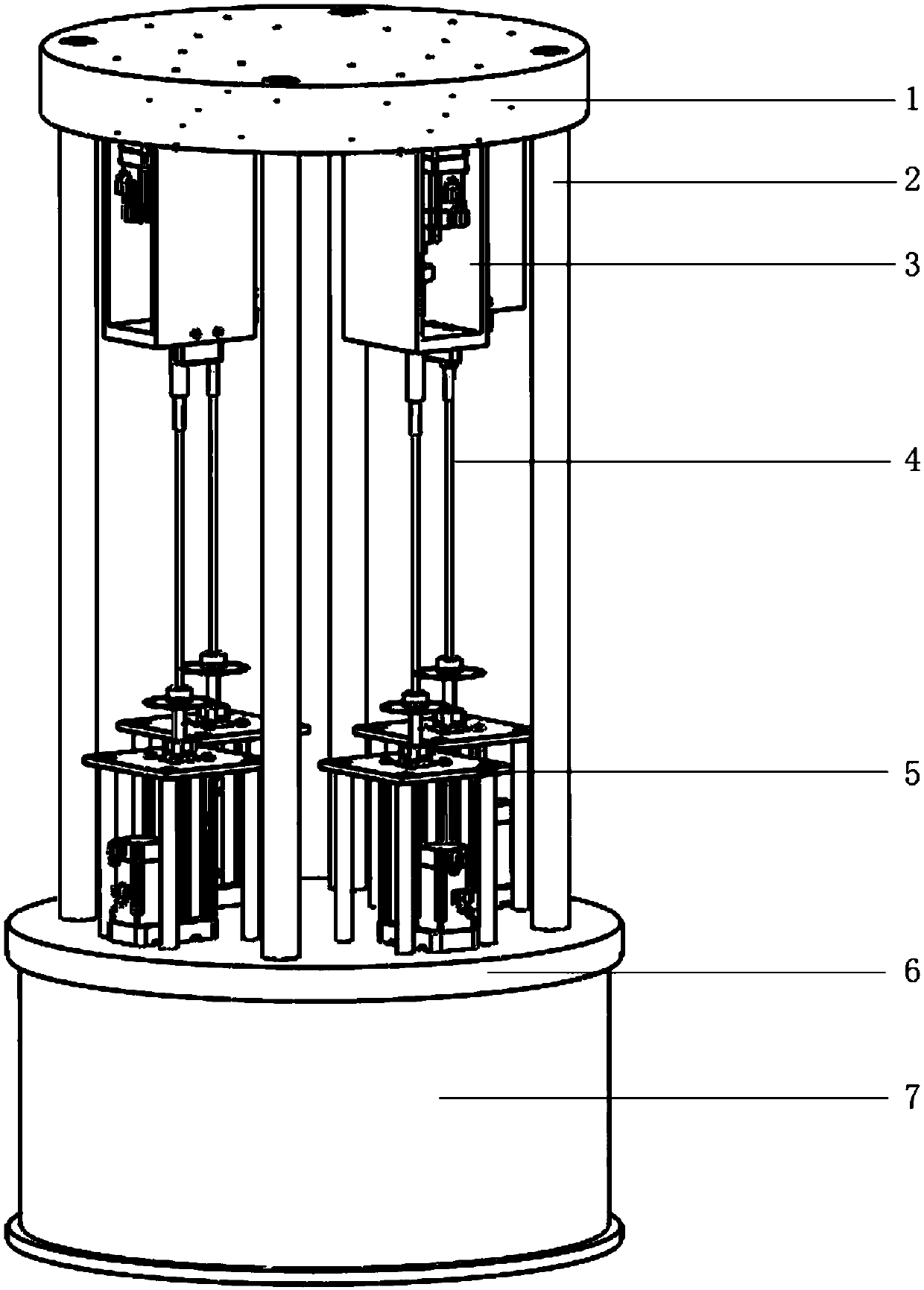

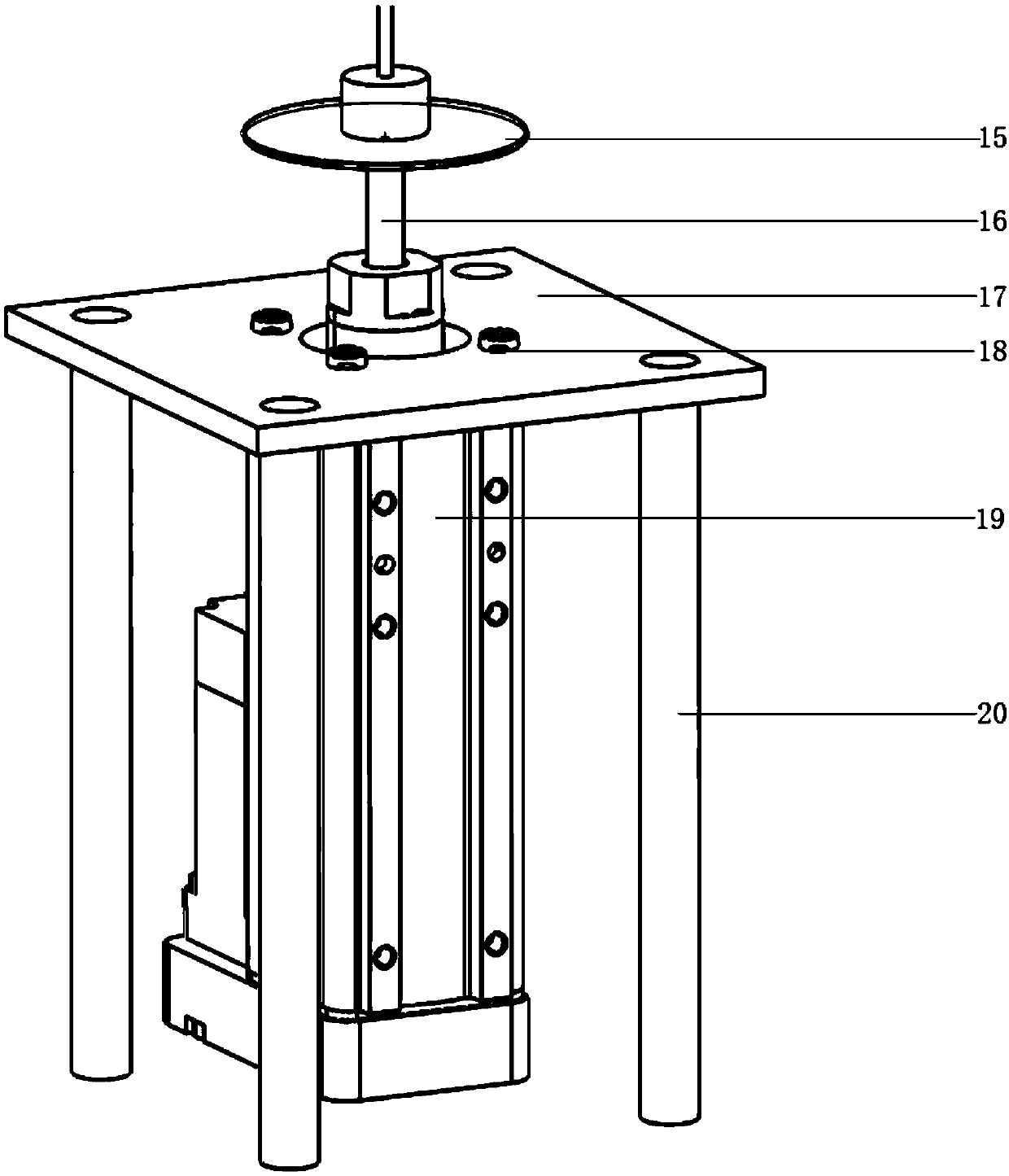

[0028] Firstly, the structural principle of the present invention is introduced. Including upper beam, support rod, upper clamping device, hanging string, lower clamping device, working platform, base and fatigue testing machine monitoring system.

[0029] Among them, there are four upper-end clamping devices and four lower-end clamping devices, which can simultaneously carry out simulated fatigue tests on four hanging strings under different working conditions.

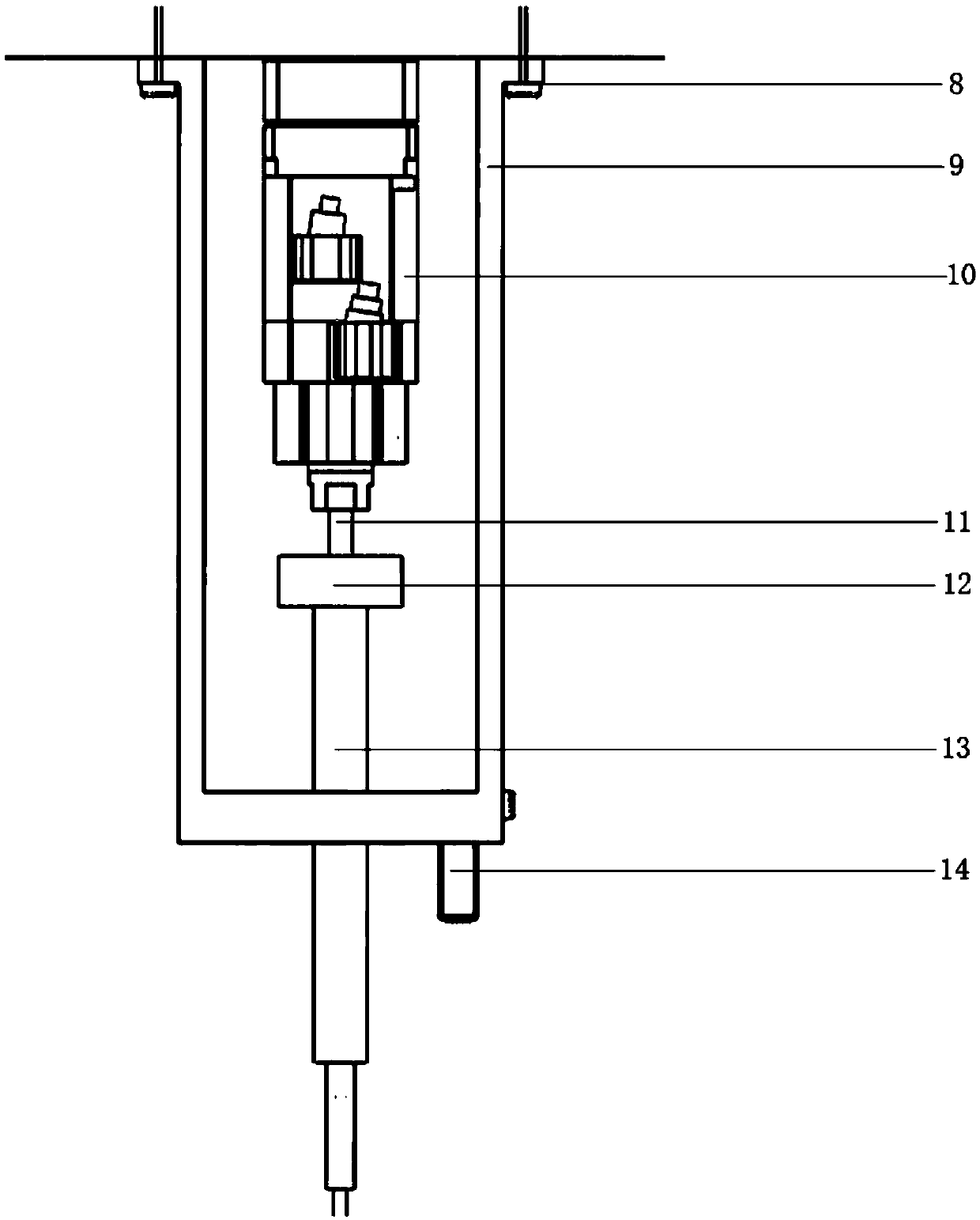

[0030] Among them, the upper clamping device includes a high-speed electric cylinder, a screw rod, a fixed bracket, a push rod and a force sensor. The high-speed electric cylinder and the fixed bracket are connected to the upper beam through a set bolt. The upper force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com