Flange binding machine

A glue-mounting machine and flange glue technology, applied in the direction of supporting insulators, electrical components, insulators, etc., can solve problems such as poor safety protection, poor compatibility, and low operability, and achieve the effect of meeting operational requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

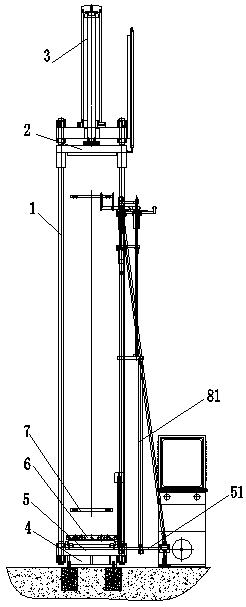

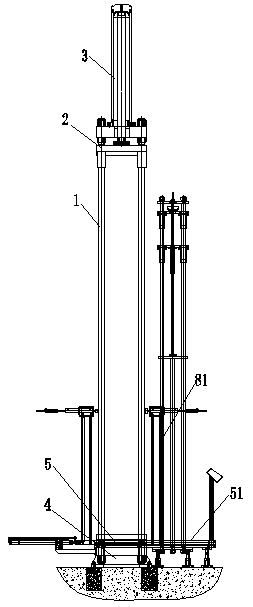

[0014] The present invention includes at least two guide rods 1 that are vertically arranged correspondingly and play a guiding role. An upper pressing plate 2 that can move up and down along the guiding rod 1 is arranged above the guiding rods 1 . There is an upper pressing plate driving device 3 for driving the upper pressing plate 2 to move up and down;

[0015] The bottom of the guide rod 1 is fixedly provided with a lower platen 4, the lower platen 4 is provided with a movable template 5, the movable template 5 can move up and down along the guide rod 1, and the upper part of the movable template 5 is provided with a The formwork 5 forms a fixedly connected flange connecting plate 6 for connecting a flange 7 .

[0016] A movable template driving device 8 is also provided to drive the movable template 5 to move up and down. The movable template driving device 8 is connected to the movable template 5 and drives the movable template 5 to move up and down.

[0017] A horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com