Car-carrying plate and intelligent parking device using car-carrying plate

A technology of vehicle-carrying boards and handling equipment, which is applied in the field of car-carrying boards, can solve the problems of long time-consuming to remove the car, difficult disassembly and replacement, complicated equipment installation, etc., to save the driver's parking time, safe and reliable use, and high mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

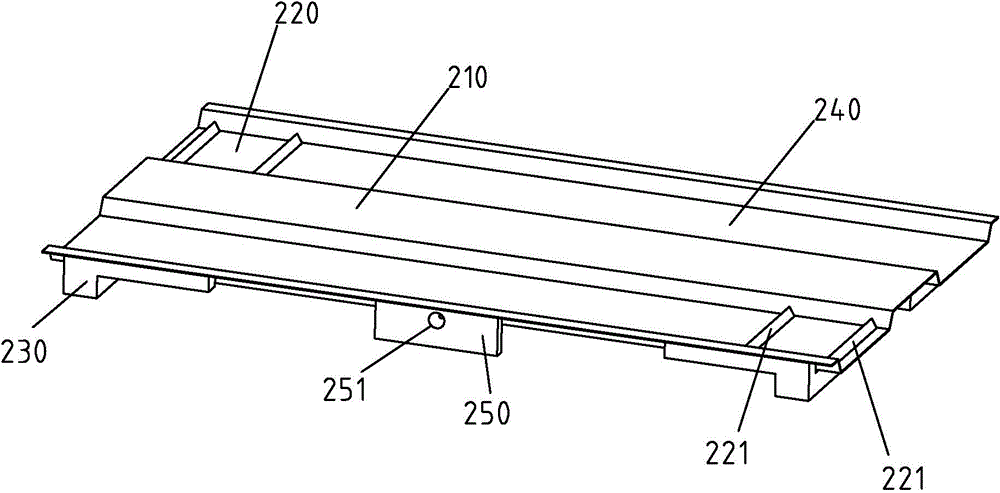

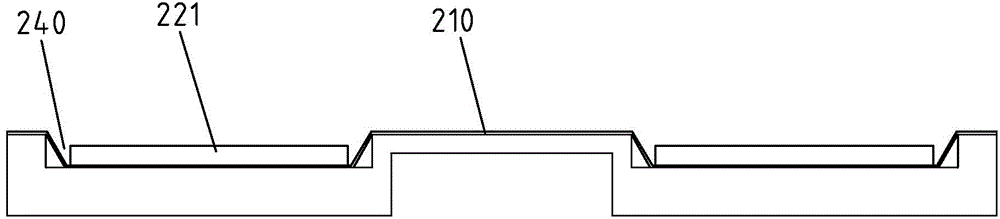

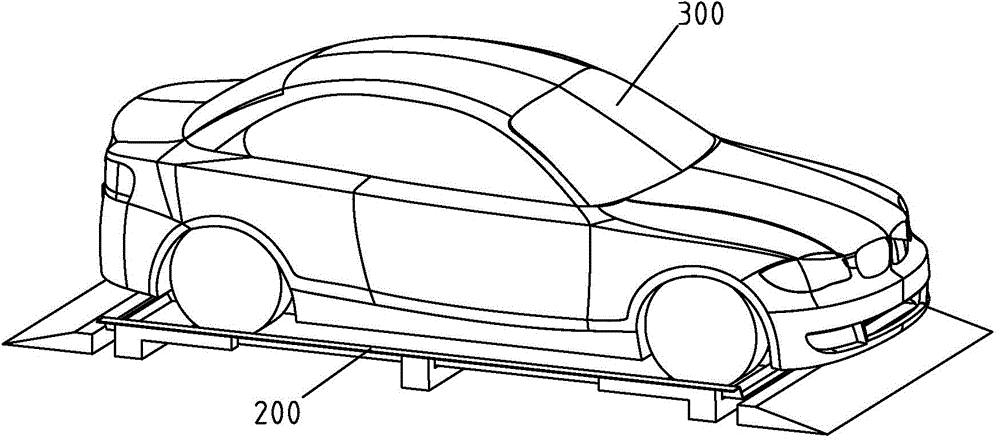

[0027] see Figure 1 to Figure 7 According to the embodiment of the vehicle loading plate 200 provided by the present invention, it includes a panel 210 and a cross beam 230 arranged at the bottom of the panel 210. The panel 210 is provided with two parallel wheel grooves 240, and the inside of the wheel grooves 240 are both A front wheel blocking groove 220 is provided, and the front wheel blocking grooves 220 in the two wheel grooves 240 are center-symmetrically distributed. The vehicle-carrying plate 200 is simple in structure and easy to process. When the car 300 drives onto the car-carrying plate 200 from any end of the car-carrying plate 200, the front wheel of the car 300 falls into the front wheel blocking groove 220 far away from the driving end of the car 300. It is limited to stop; when the bottom torque cannot be driven out, the driver can clearly feel that the vehicle has been parked in place, which greatly improves the efficiency of correct parking of the vehicle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com