X-band variable-polarization microwave front-end assembly

A front-end component, X-band technology, applied in the field of variable-polarization microwave front-end components in X-band, can solve the problems of complex microwave control network, inability to achieve 45-degree oblique polarization polarization, etc., to reduce component volume, increase support, reduce The effect of microwave loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

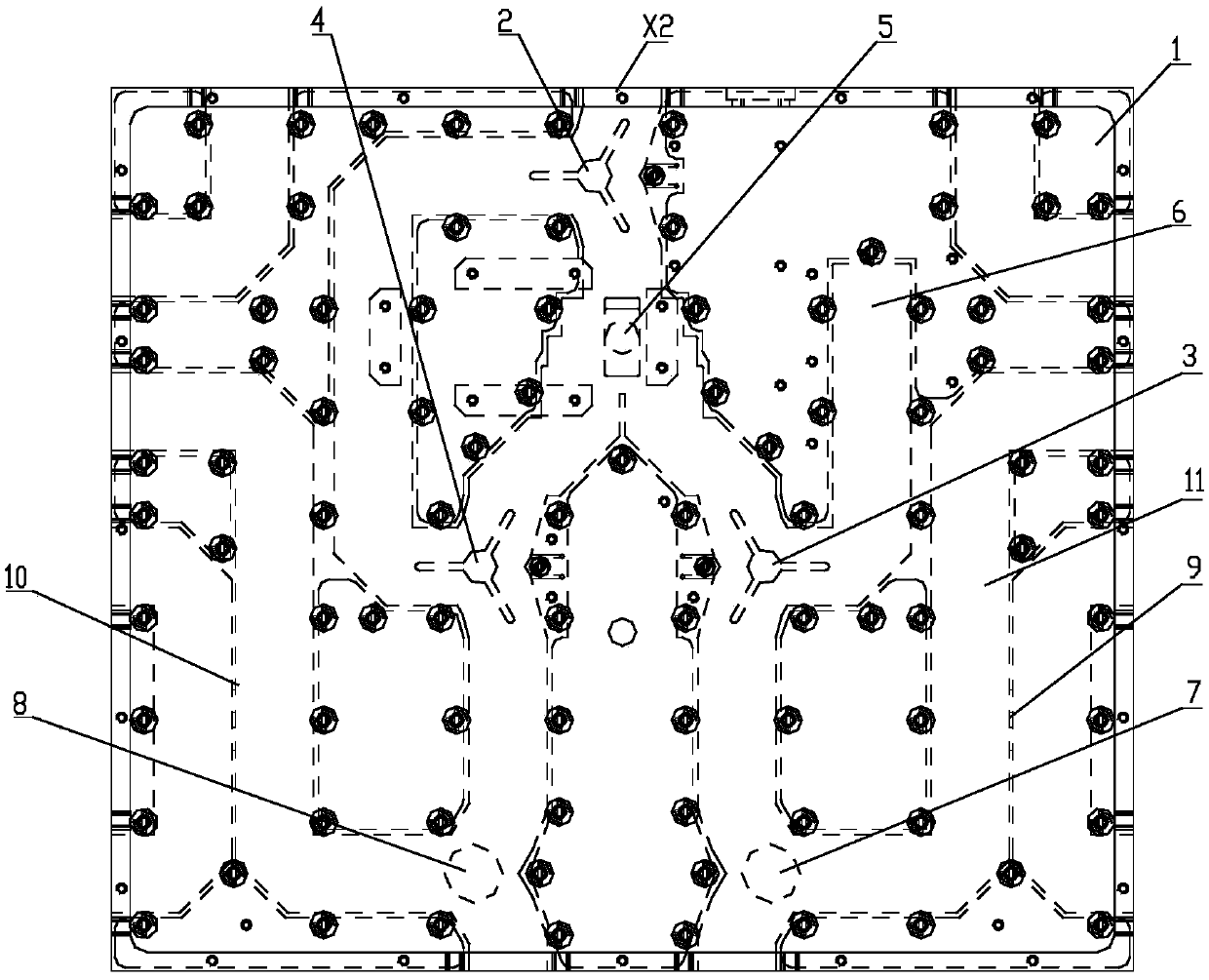

[0017] An X-band polarization-variable microwave front-end assembly according to the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. The examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0018] An X-band variable polarization microwave front-end component, such as figure 1 As shown, including: cavity, ferrite switch junction K1, ferrite switch junction K2, ferrite switch junction K3, circulator H1, circulator H2, magic T, waveguide section L1, directional coupler O1, directional Coupler O2, the cavity is a closed waveguide; ferrite switch junction K1, ferrite switch junction K2, ferrite switch junction K3, circulator H1, circulator H2, magic T and waveguide section L1 pass through a straight waveguide or a bend The microwave network formed by the waveguide is set in the cavity; the magic T is connected with the ferrite switch junct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com