Pipe bus suspension fitting

A technology for pipe busbars and fittings, which is applied to the installation of busbars, open busbars, and electrical components. It can solve the problems of inconvenient installation and operation and low installation efficiency, and achieve high installation efficiency, convenient installation, and convenient processing, manufacturing and assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

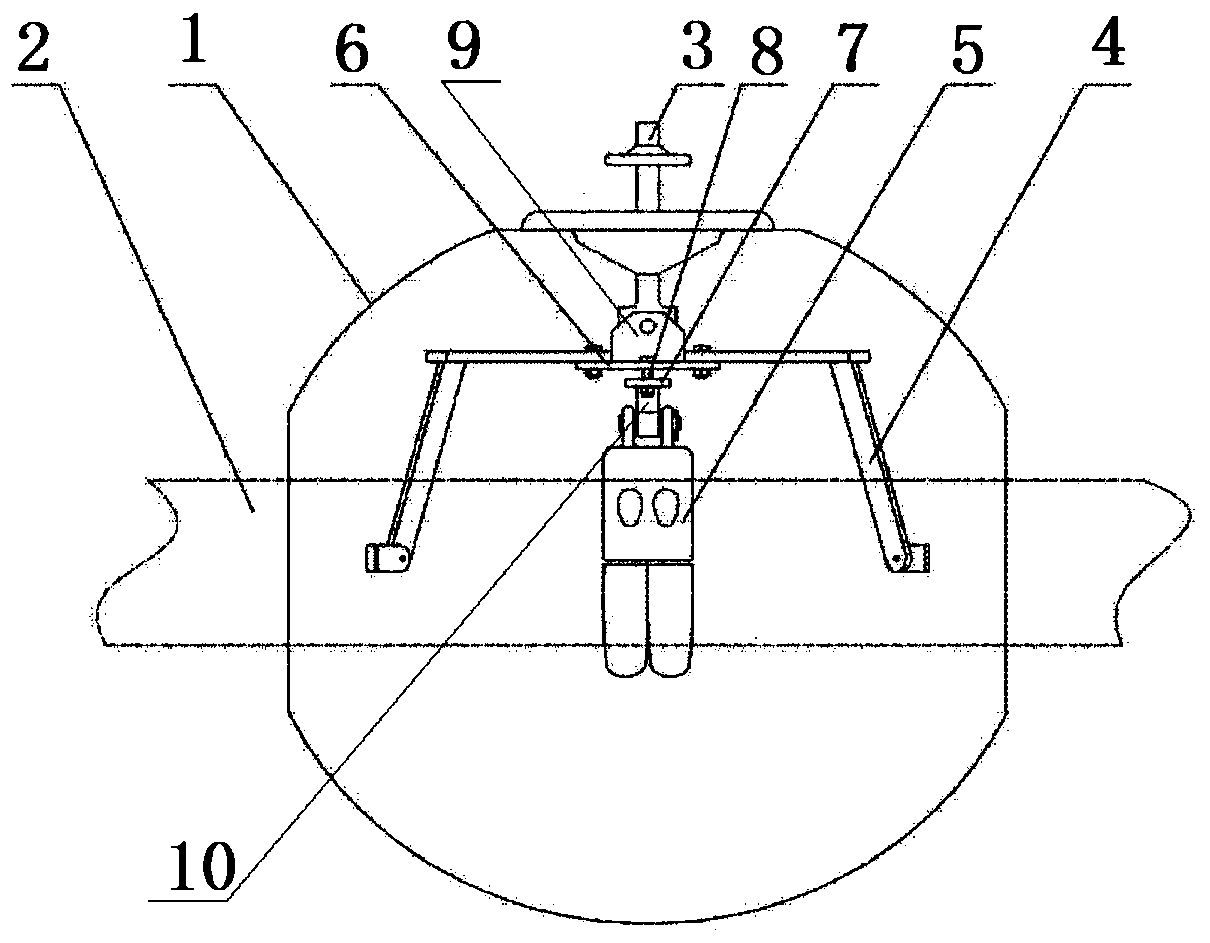

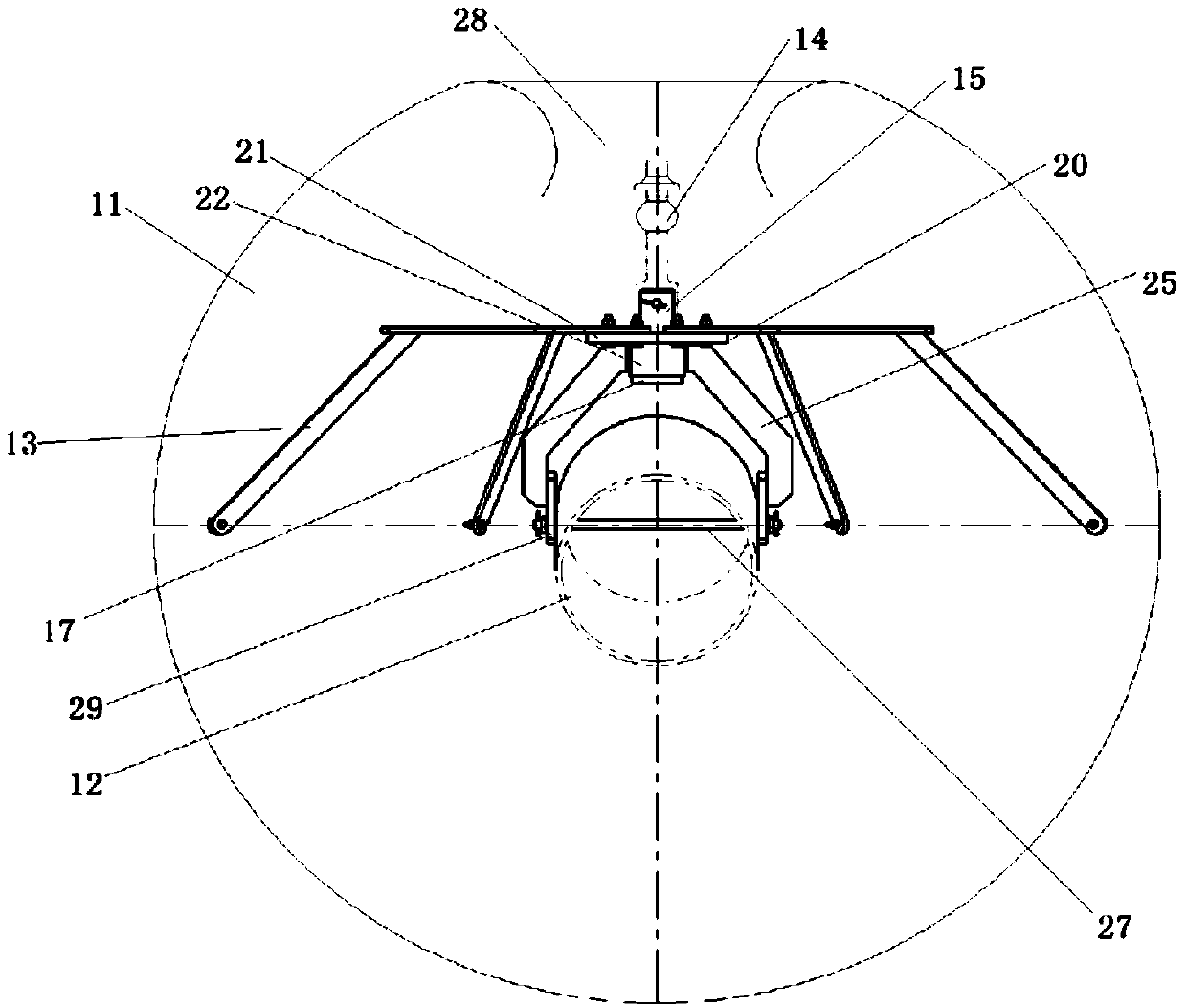

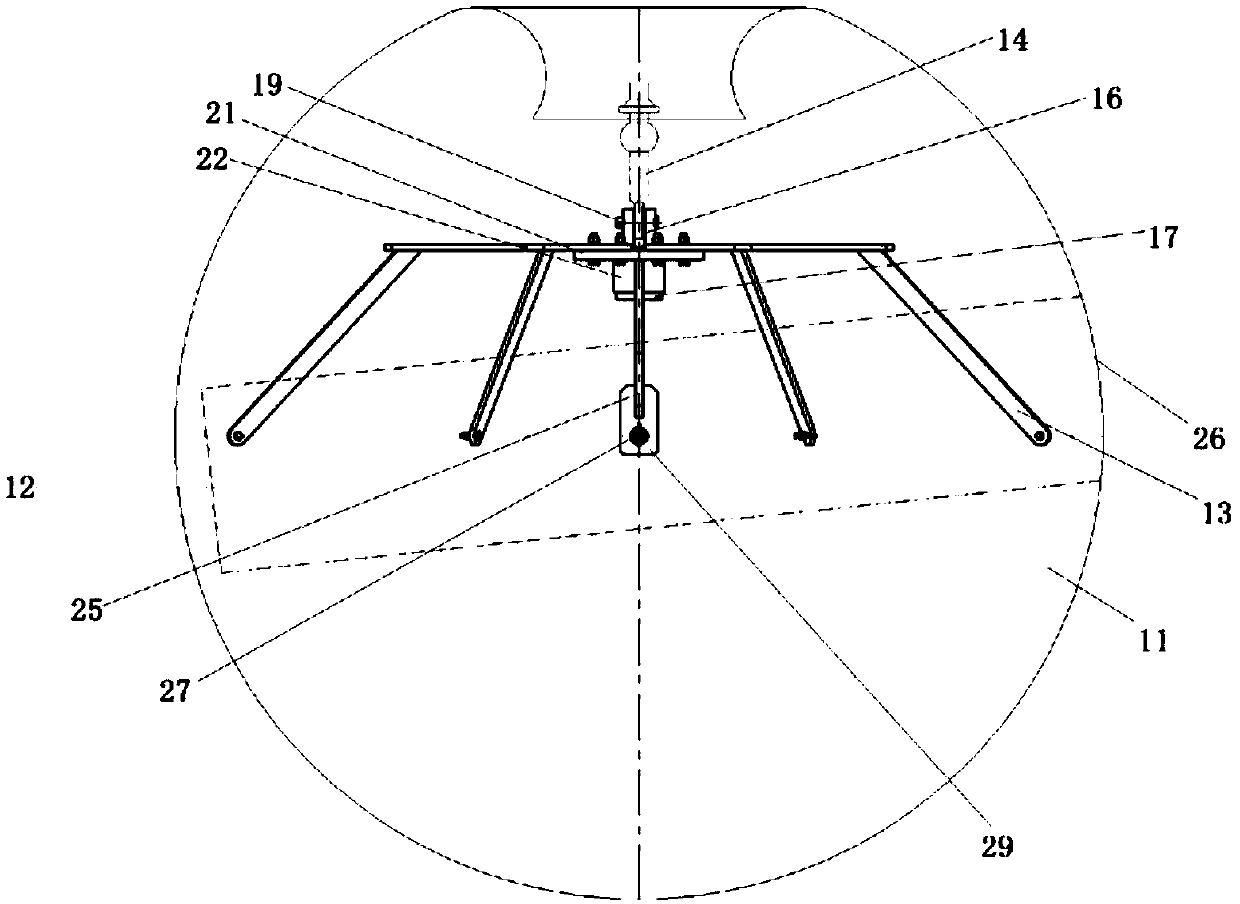

[0032] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] The specific embodiment of the pipe busbar suspension fittings provided by the present invention is suitable for ±800kV UHV DC converter stations, such as figure 2 with image 3 As shown, it includes a shielding ball 11 and a support frame arranged in the shielding ball 11, wherein the shielding ball 11 includes upper and lower hemispheres, and the support frame includes a support arm 13 that is fixedly connected to the inner wall surface of the shielding ball 11 by bolts. , the support frame is provided with a hoisting structure for hoisting the pipe bus 12 and is rotatably equipped with a connecting rod 15 whose rotation axis extends in the up and down direction, and the shielding ball 11 is provided with a pipe bus perforation 26 for the pipe bus 12 to pass through, for the support frame The suspension through hole 28 connected with the suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com