Ceramic cup efficient in heat insulation and temperature preservation and production process thereof

A technology of thermal insulation and ceramic cups, which is applied in the field of ceramic cups, can solve the problems of heat loss, poor thermal insulation performance, and inability to achieve thermal insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

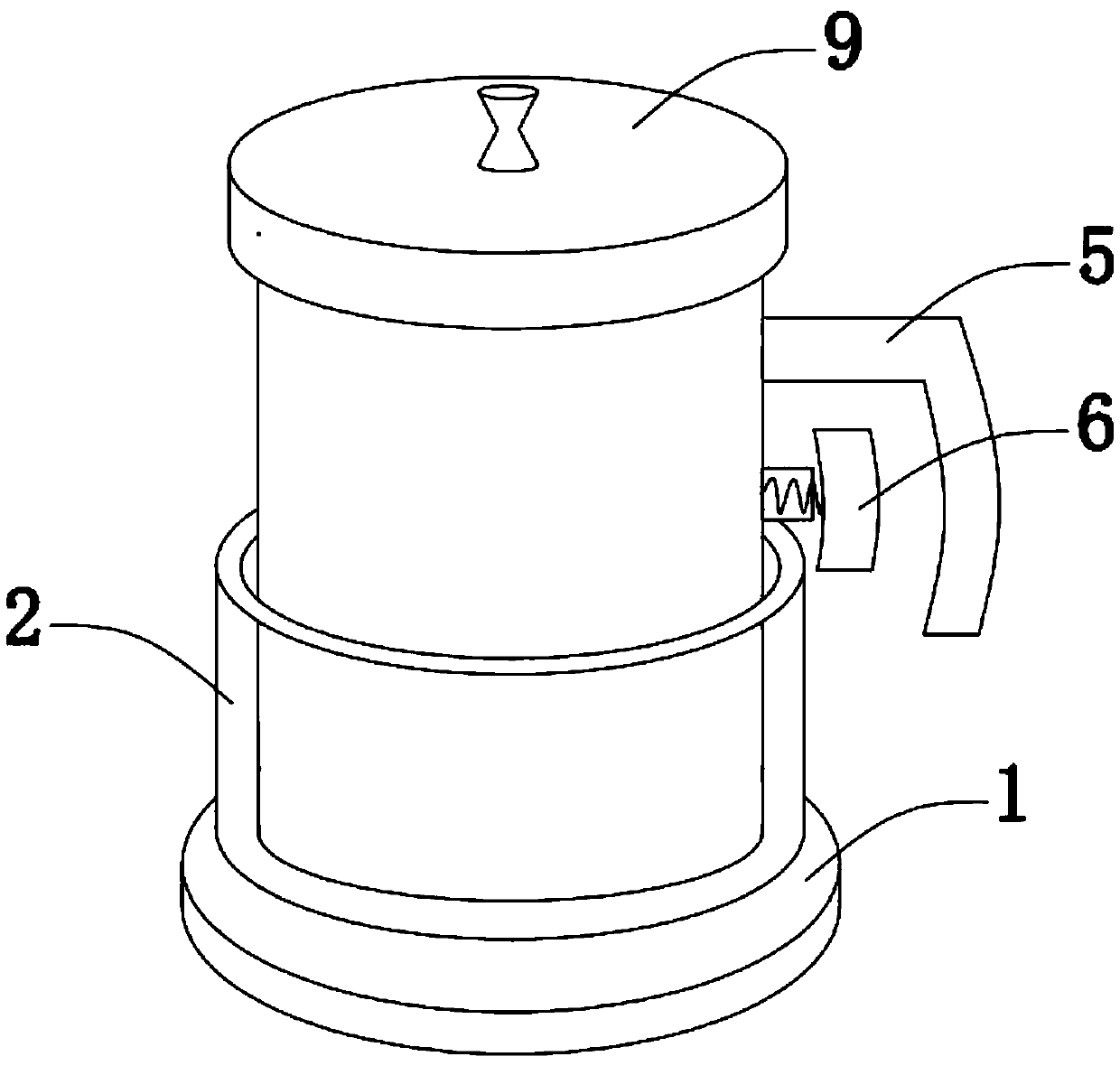

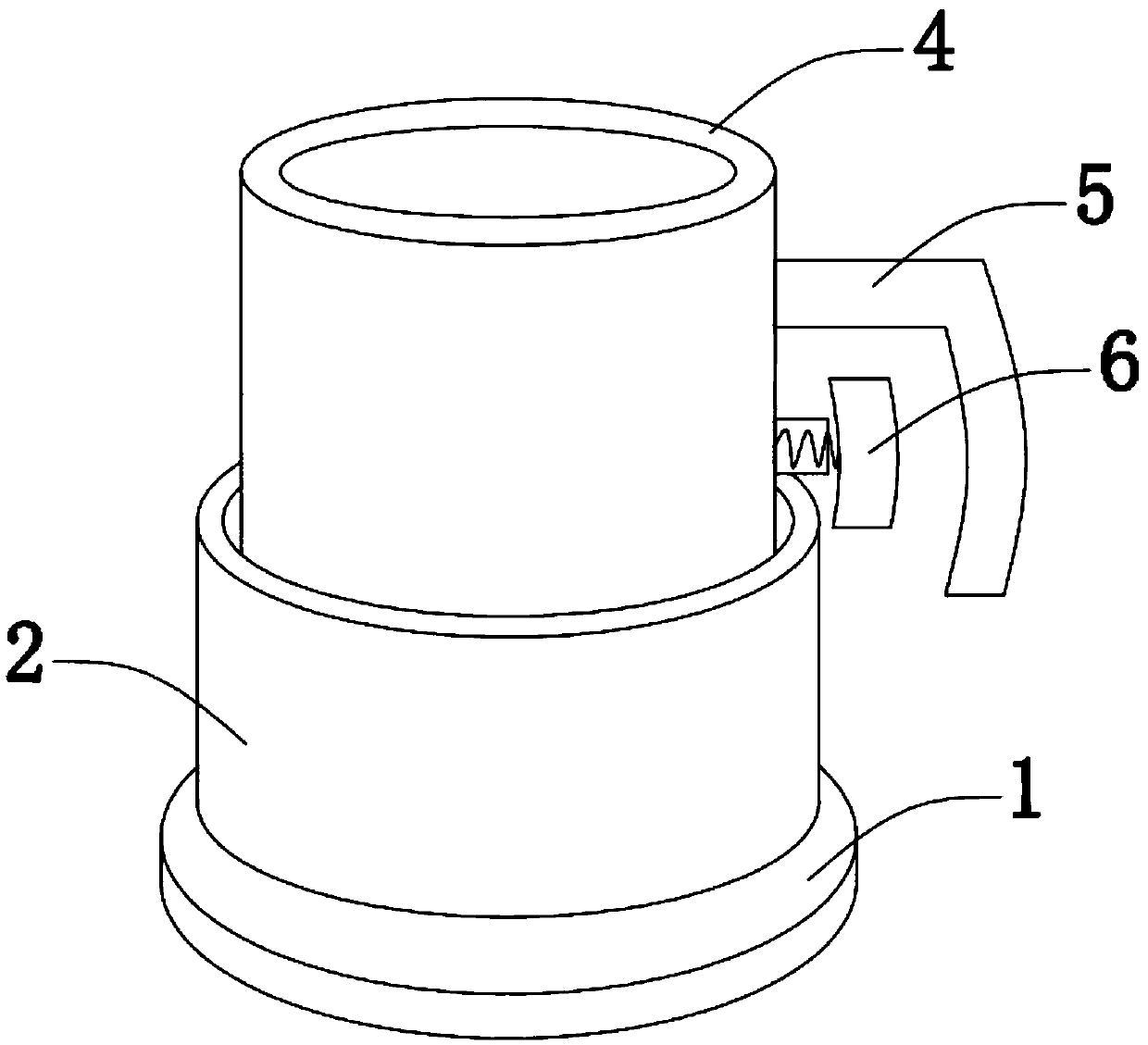

[0034] The present invention provides such Figure 1-6 A thermal insulation high-efficiency ceramic cup, comprising a coaster 1, a ceramic cup body 4 and a cup cover 9, the upper end of the coaster 1 is connected with a cup cover 2, and the ceramic cup body 4 is placed in the cup cover 2, The outer side of the ceramic cup body 4 is connected with a handle 5, the bottom of the handle 5 is located on the ceramic cup body 4 and connected with a rubber sleeve 8, and the rubber sleeve 8 is connected with a spring 7 by a bolt, and the spring 7 One end extends to the outside of the rubber sleeve 8 and is connected with a rubber block 6. The cup cover 9 is covered on the upper end of the ceramic cup body 4, and the inside of the ceramic cup body 4 is provided with a cavity for placing a stainless steel liner 11, and The cavities on both sides of the stainless steel lining 11 are also filled with activated carbon layers 10 .

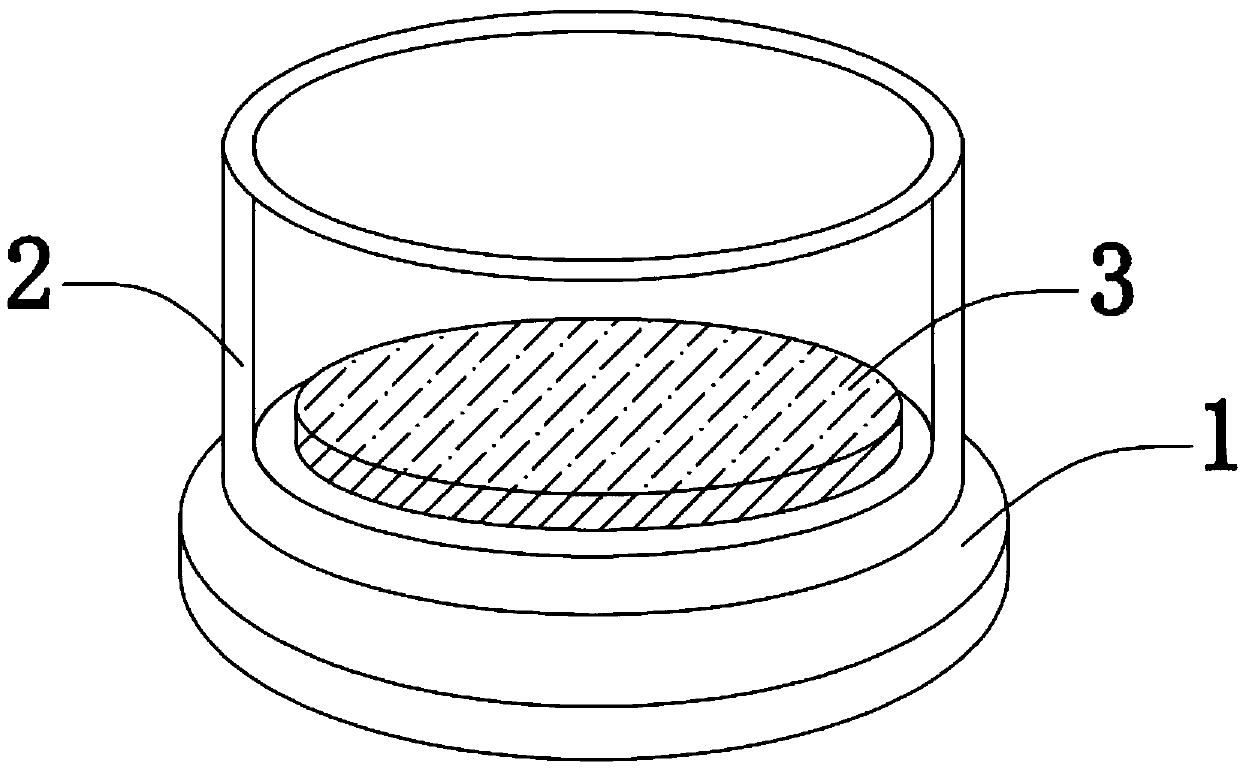

[0035] Specifically, a rubber pad 3 is provided on the upp...

Embodiment 2

[0055] The present invention provides such Figure 1-6 A thermal insulation high-efficiency ceramic cup, comprising a coaster 1, a ceramic cup body 4 and a cup cover 9, the upper end of the coaster 1 is connected with a cup cover 2, and the ceramic cup body 4 is placed in the cup cover 2, The outer side of the ceramic cup body 4 is connected with a handle 5, the bottom of the handle 5 is located on the ceramic cup body 4 and connected with a rubber sleeve 8, and the rubber sleeve 8 is connected with a spring 7 by a bolt, and the spring 7 One end extends to the outside of the rubber sleeve 8 and is connected with a rubber block 6. The cup cover 9 is covered on the upper end of the ceramic cup body 4, and the inside of the ceramic cup body 4 is provided with a cavity for placing a stainless steel liner 11, and The cavities on both sides of the stainless steel lining 11 are also filled with activated carbon layers 10 .

[0056] Specifically, a rubber pad 3 is provided on the upp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap