Dynamic powder paving system for additive manufacturing

A technology of additive manufacturing and powder spreading, which is applied in the field of additive manufacturing, can solve the problems of large device size, etc., and achieve the effects of reducing operating power consumption, saving costs, and saving powder consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

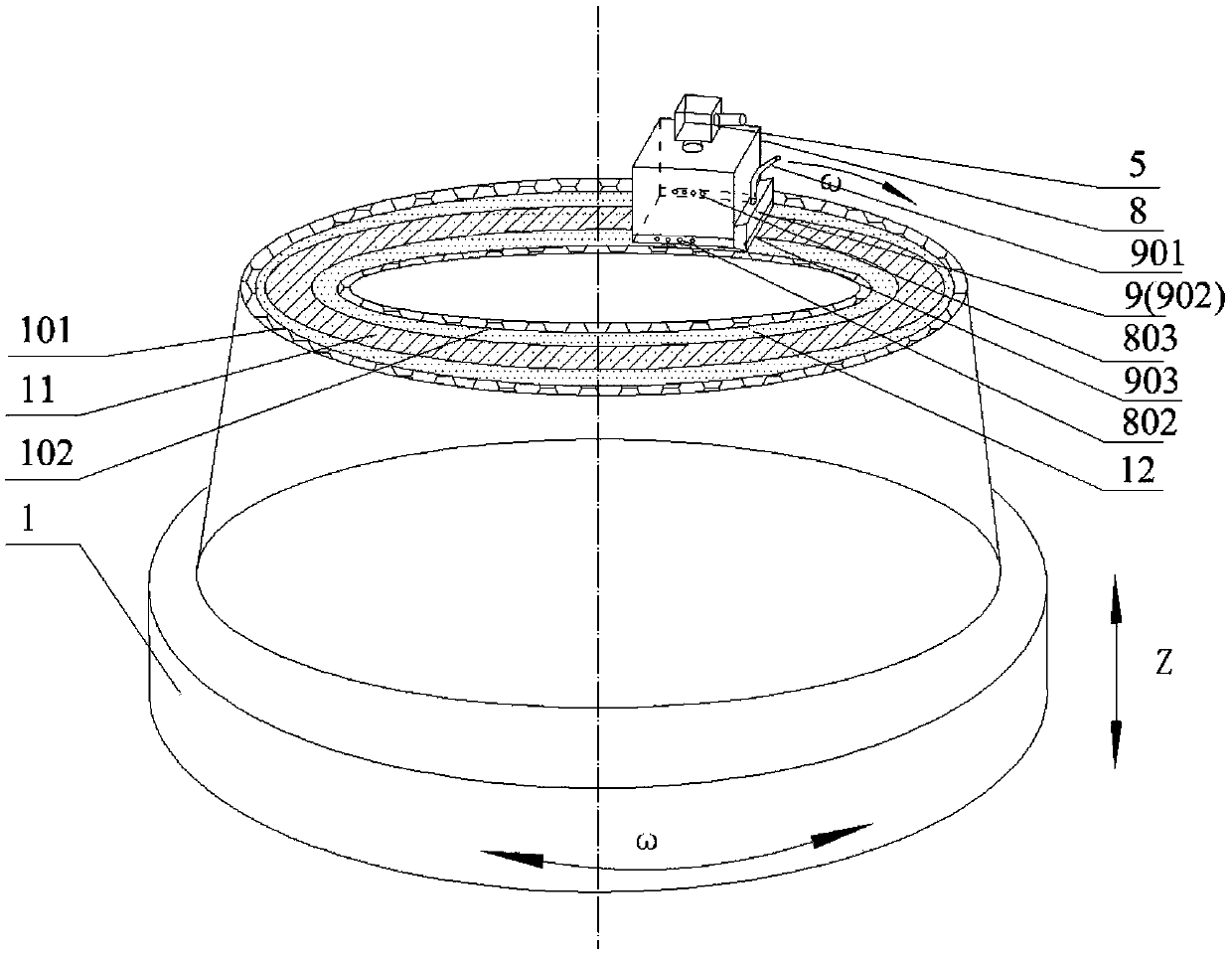

[0047] Such as figure 1 As shown, the powder cylinder is composed of the first side wall and the second side wall. Its overall shape and size are determined according to the shape characteristics of the parts to be processed. The size of the powder cylinder is slightly larger than the maximum cross-sectional size of the parts to be formed (the first The side wall and the second side wall and the shaped base plate as the bottom surface constitute the part shaped area).

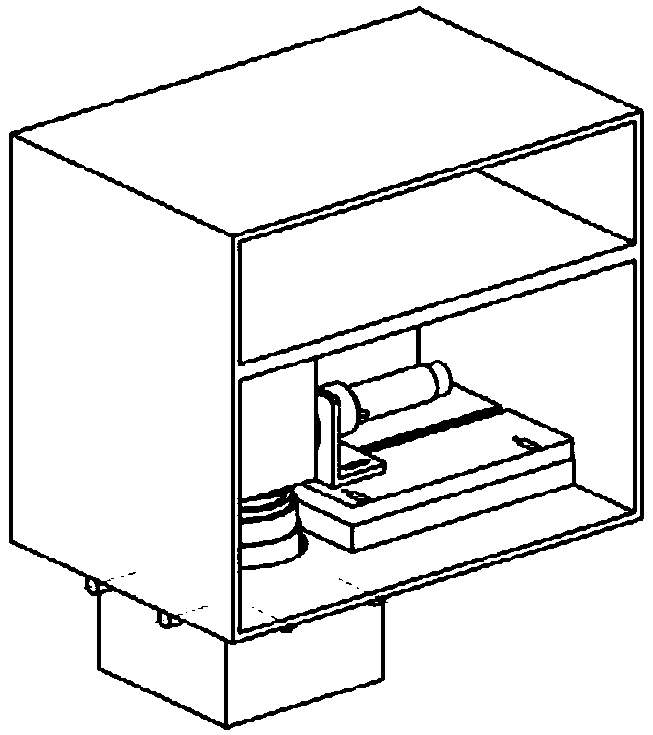

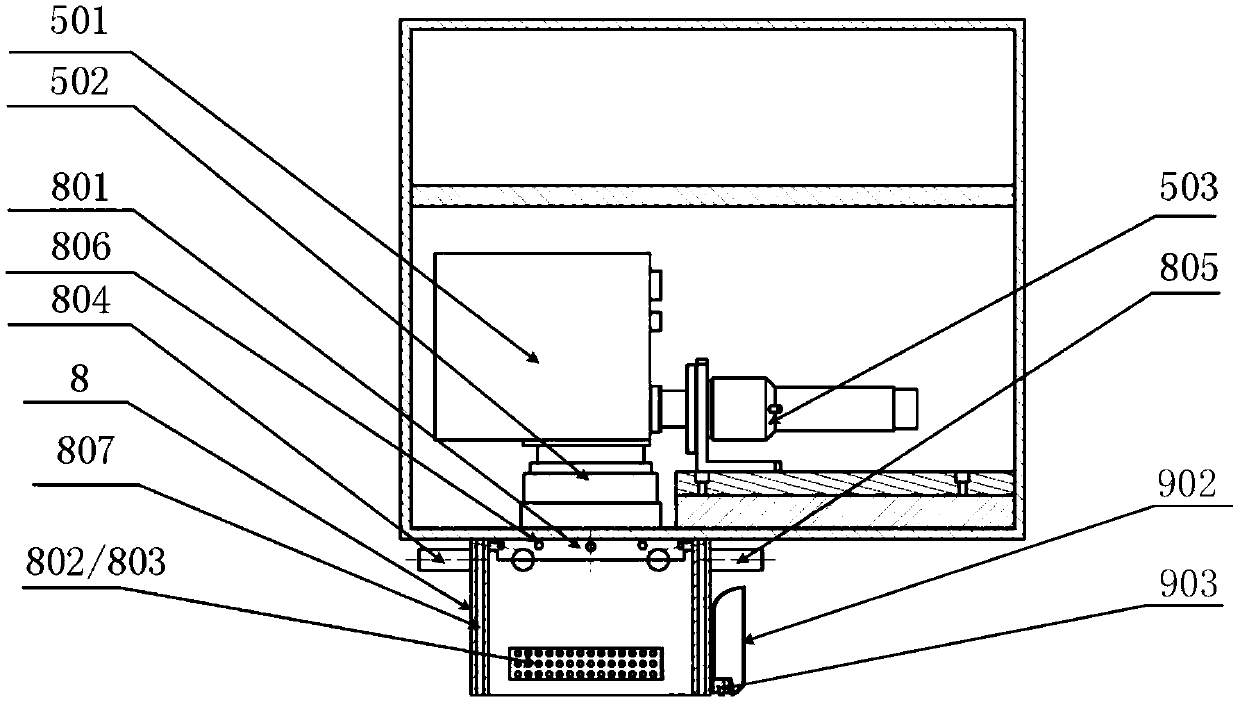

[0048] Such as figure 1 , image 3 As shown, a local powder spreading device is installed on the bottom of the partial powder bed shield along the circumferential direction of the powder cylinder, and a scraper is installed at the bottom, and the scraper is a flexible scraper or a hard scraper. The scraper is positioned between the first side wall and the second side wall of the powder cylinder, and can be slightly lower than the lower end surface of the partial powder bed protective cover (a certain gap is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com