ink dosing filler

A filler and ink technology, applied in printing and other directions, can solve the problems of price reduction work efficiency, filling volume error, and the inability to set multiple quantifications, etc., and achieve the effect of smooth movement and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

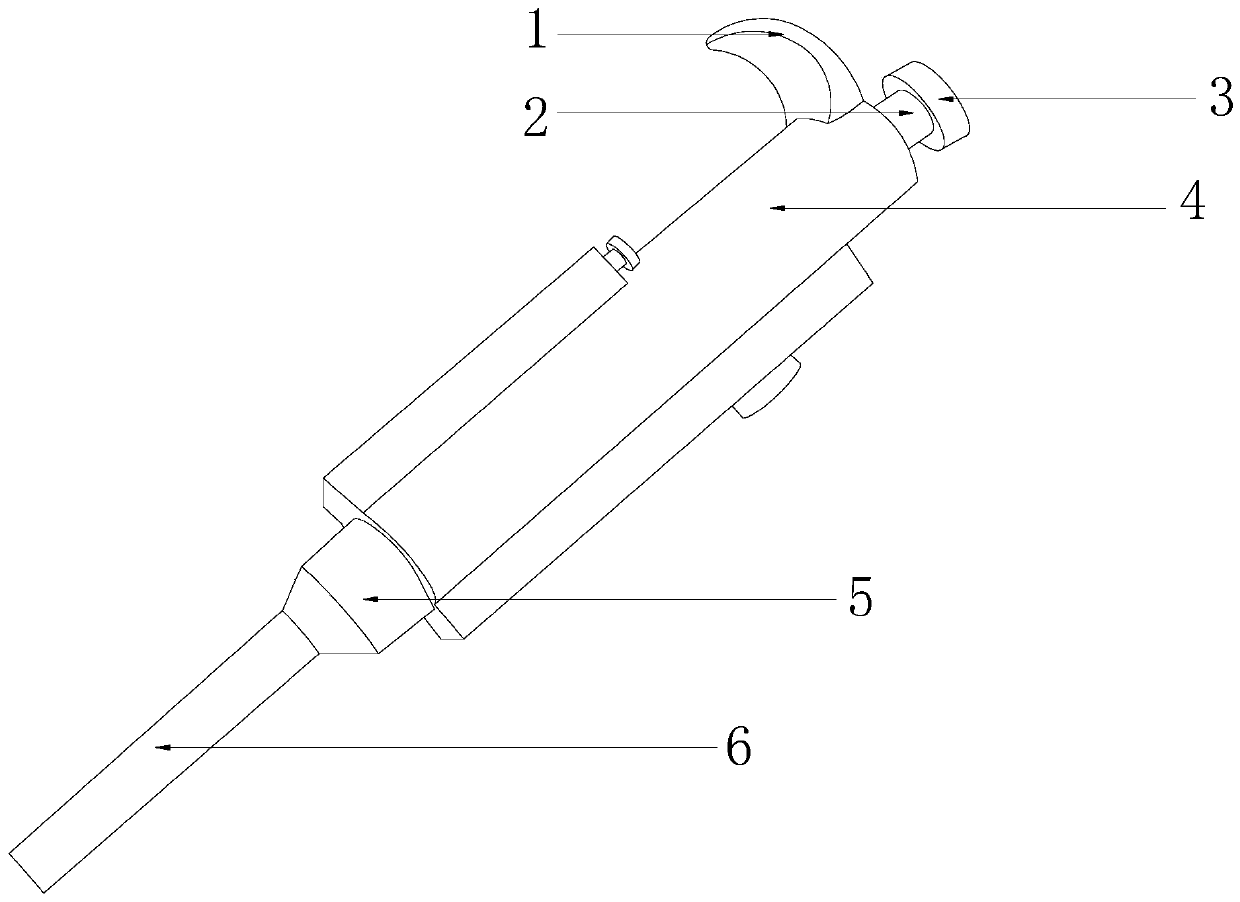

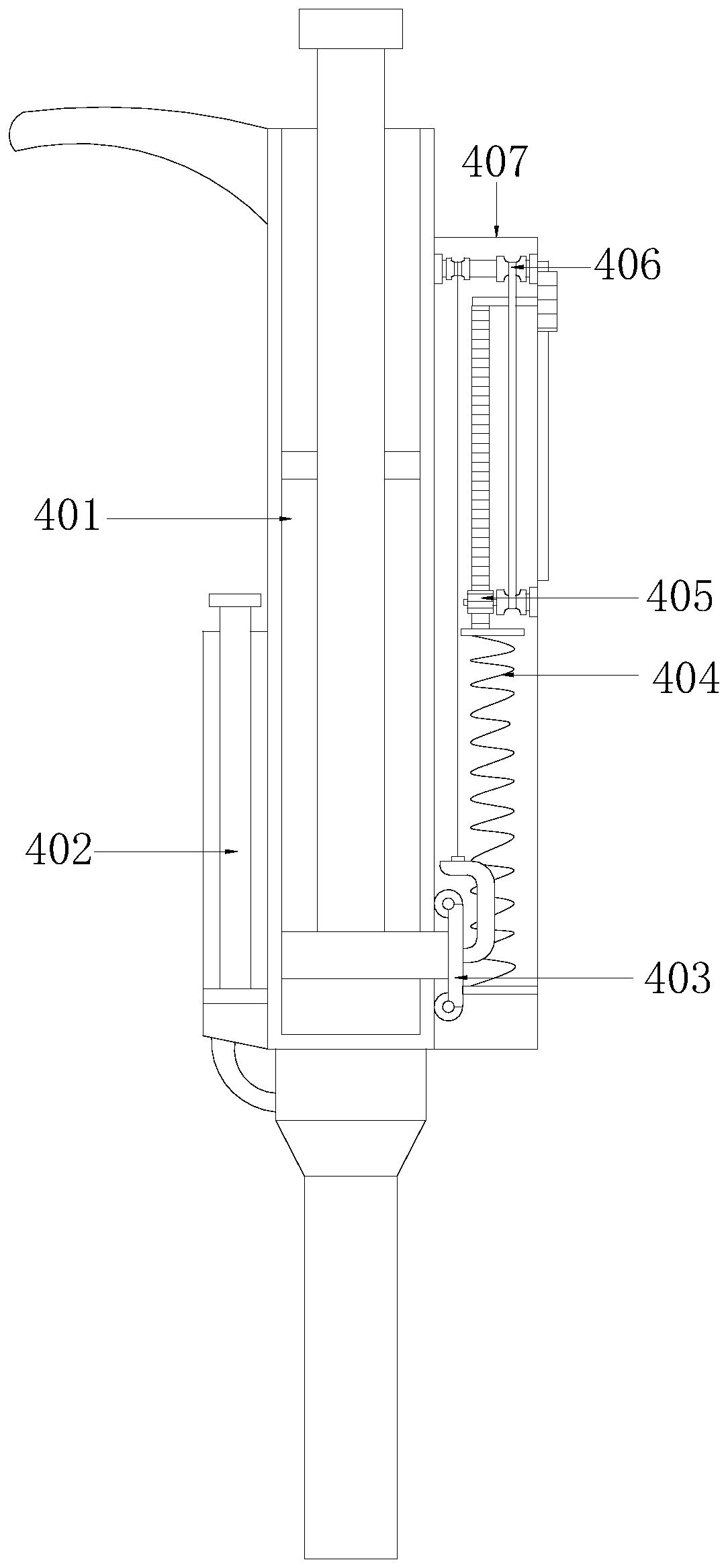

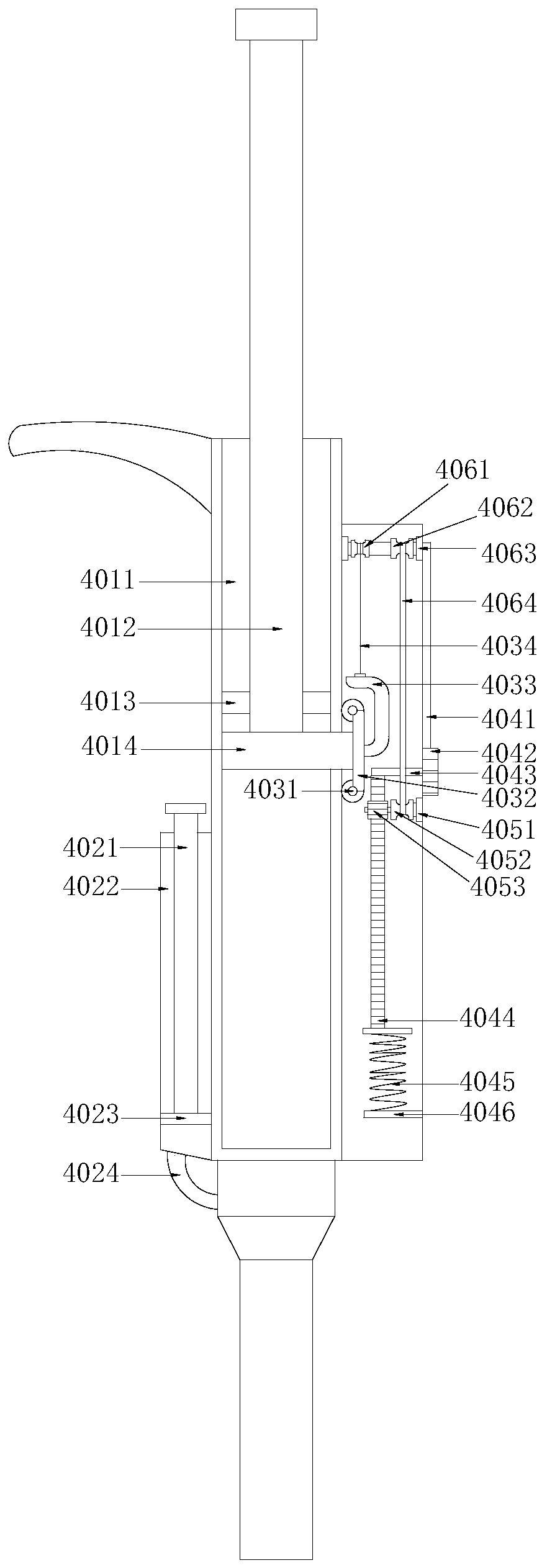

[0021] see Figure 1-Figure 4, the present invention provides an ink quantitative filler, its structure includes finger button 1, filling push rod 2, circular pressure plate 3, filling cylinder 4, installation joint 5, filling head 6, and described filling head 6 connects filling cylinder through installation joint 5 4 are connected at the bottom, the filling push rod 2 is installed inside the filling cylinder 4 by embedding, and a circular pressure plate 3 is provided on the top, and the finger buckle 1 is arranged on the left end of the top of the filling cylinder 4, and is an integrated structure, so The installation joint 5 and the filling head 6 are an integrated structure, and the filling cylinder 4 includes a main body 401, an emptying device 402, a driving mechanism 403, a limit mechanism 404, a linkage mechanism 405, a transmission mechanism 406, and an installation groove 407. The device 402 is installed on the left lower end of the main body 401 by buckling, the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com