Method for sealing joint of insulating blocks of B type enclosure system

A technology for insulating blocks and joints, which is applied in the field of sealing the joints of insulating blocks of B-type enclosure systems, can solve the problems of extrusion and friction of insulating blocks, failure of tightness of joints of insulating blocks, deformation of bulkheads, etc., to prevent extrusion. Pressure, damage prevention, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

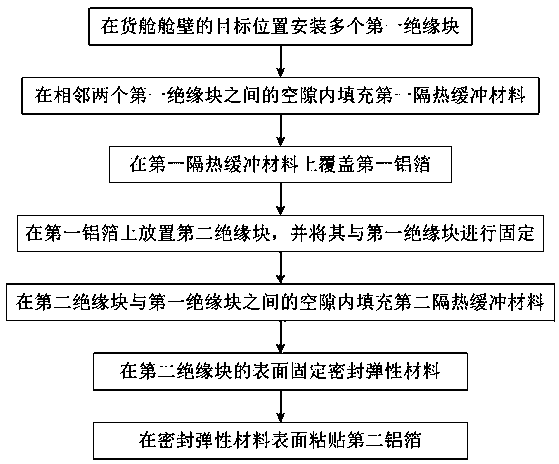

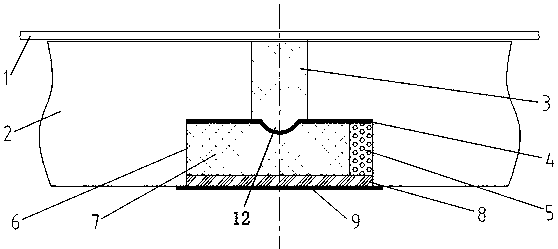

[0049] Embodiment 1, the method of the present invention for sealing the connection of insulating blocks of a B-type containment system specifically includes the following steps:

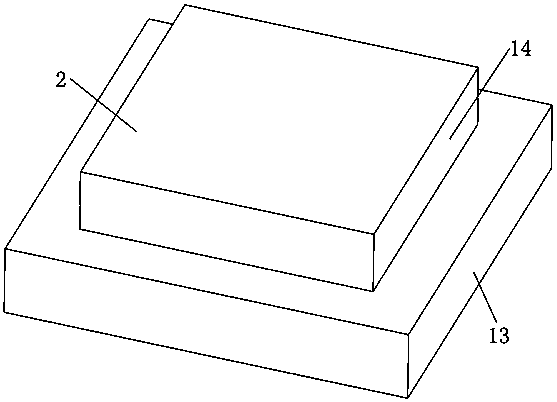

[0050] Step 1: Use bolts to fix multiple first insulating blocks 2 with a convex longitudinal section at the target position at the bottom of the cargo hold (cargo hold bulkhead 1), so that a 20mm gap is formed between the lower sides of two adjacent first insulating blocks 2 A first gap 10 of 40 mm, and a gap between the upper sides of two adjacent first insulating blocks is a second gap 11 .

[0051] Setting the first gap between two adjacent first insulating blocks 2 can ensure that there is a sufficient buffer gap between the two opposing insulating blocks when the bulkhead deforms without mutual extrusion.

[0052] When installing the first insulating block 2, it should be ensured that the deviation between the installation position and level of the first insulating block 2 and the theoretical ...

Embodiment 2

[0061] Embodiment 2. The difference between this embodiment and Embodiment 1 is that the width of the first aluminum foil 4 fixed in step 3 is larger than the width of the first gap 10 and smaller than the width of the second gap 11 . At this time, when fixing the first aluminum foil 4 , the diversion groove 12 in the center of the first aluminum foil 4 should be located in the middle of the first cavity 10 . After the first aluminum foil 4 is fixed, the second insulating block 7 is fixed.

[0062] The second insulating block 7 has two fixing methods:

[0063] The first fixing method is to bond the lower surface of the second insulating block 7 on the bosses of the left and right first insulating blocks, so that the two side surfaces and the left and right first insulating blocks are left. There is a certain gap, and then the second thermal insulation buffer material 5 is filled respectively between these two gaps.

[0064] The second fixing method is to bond the left side a...

Embodiment 3

[0066] Embodiment 3, the method for sealing the connection of insulating blocks of the B-type containment system of the present invention specifically includes the following steps:

[0067] Step 1: Fix a plurality of first insulating blocks 2 with a convex longitudinal section at the target position on the top of the cargo hold, so that a first gap 10 of 20mm-40mm is formed between the lower sides of two adjacent first insulating blocks. The gap between the upper sides of two adjacent first insulating blocks is the second gap 11 .

[0068] Step 2: filling the first gap 10 with the first thermal insulation buffer material 3 .

[0069] Step 3: Place the second insulating block 7 on the first thermal insulation buffer material 3 , the width of the second insulating block 7 is larger than the width of the first gap 10 and smaller than the width of the second gap 11 .

[0070] Step 4: Fix the second insulating block 7 and the first insulating block 2 through the adhesive 6, and le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com