A device for automatic pretensioning of solar wing compression rod

A technology of pressing rod and sun, which is applied in the field of precise adjustment of space deployable mechanism, can solve the problems of low efficiency, low precision, and high risk of pressing operation of solar wings, so as to improve reliability, improve efficiency, and improve structural setting. clever effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

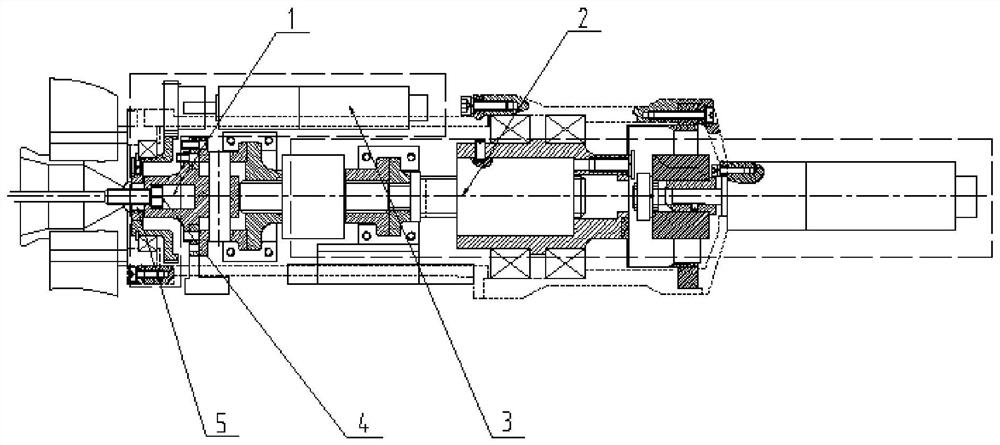

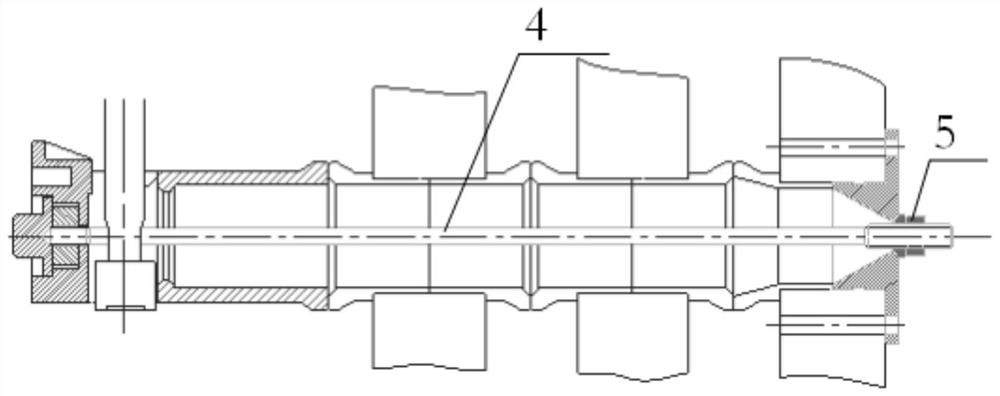

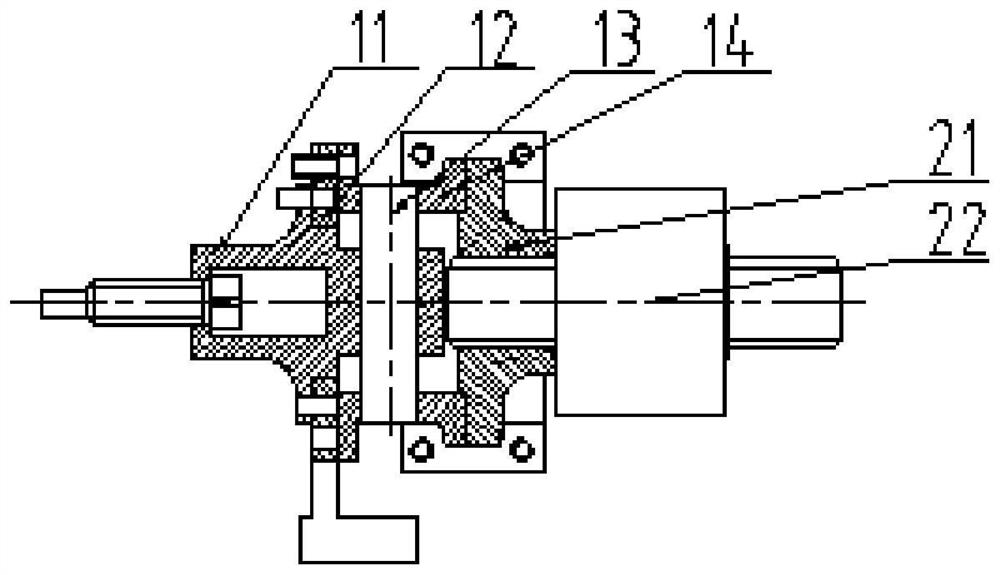

[0038] During the installation of the solar wing, it is necessary to press each piece of the solar wing on the side plate of the satellite through the pressing rod 4, such as figure 2 As shown, the three sections of the solar wing are compressed on the side of the satellite body, and the compression nut 5 provides a certain pre-tightening force for the compression rod 4 through threaded connection, and the pre-tightening force of the compression rod 4 needs to be precisely controlled at a reasonable In the range. When the compression nut 5 is manually tightened, though the pretightening force can be controlled within a certain range by controlling the number of tightening turns. However, due to the friction between the compression nut 5 and the surface of the workpiece to be pressed, it greatly affects the size of the preload force of the compression rod 4 . Therefore, it is difficult to precisely control the pretightening force within a reasonable range by manually turning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com