Mounted feeding device matched with spiral chutes for use

A technology of spiral chute and feeding device, which is applied in the direction of conveying bulk materials, transportation and packaging, conveyors, etc., and can solve problems such as poor tiling effect of ore sand inside the water flow, uneven distribution of ore sand inside the water flow, and affecting the classification effect of ore sand flow. , to achieve the effect of improving ore classification effect and ensuring the effect of ore classification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

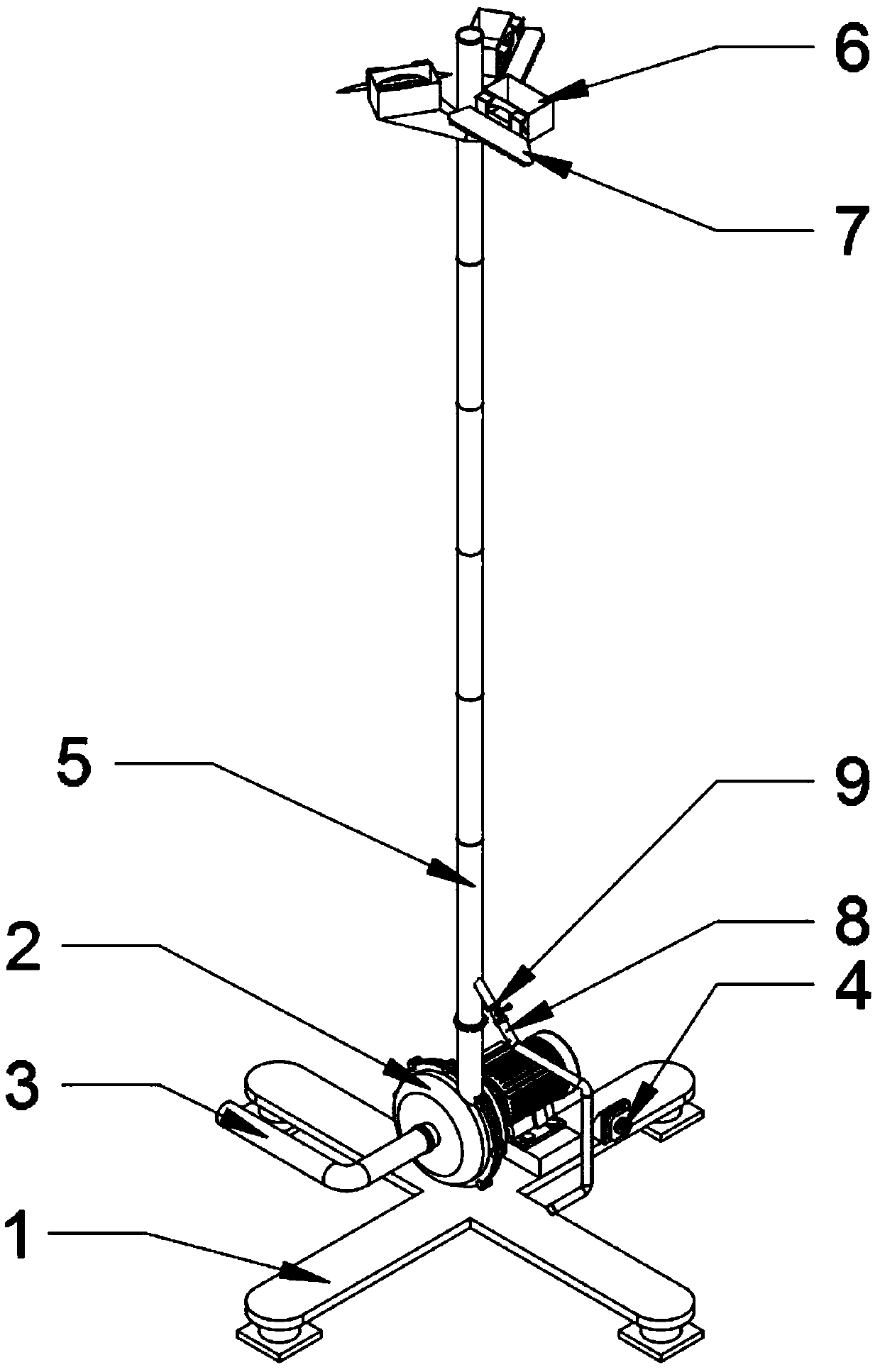

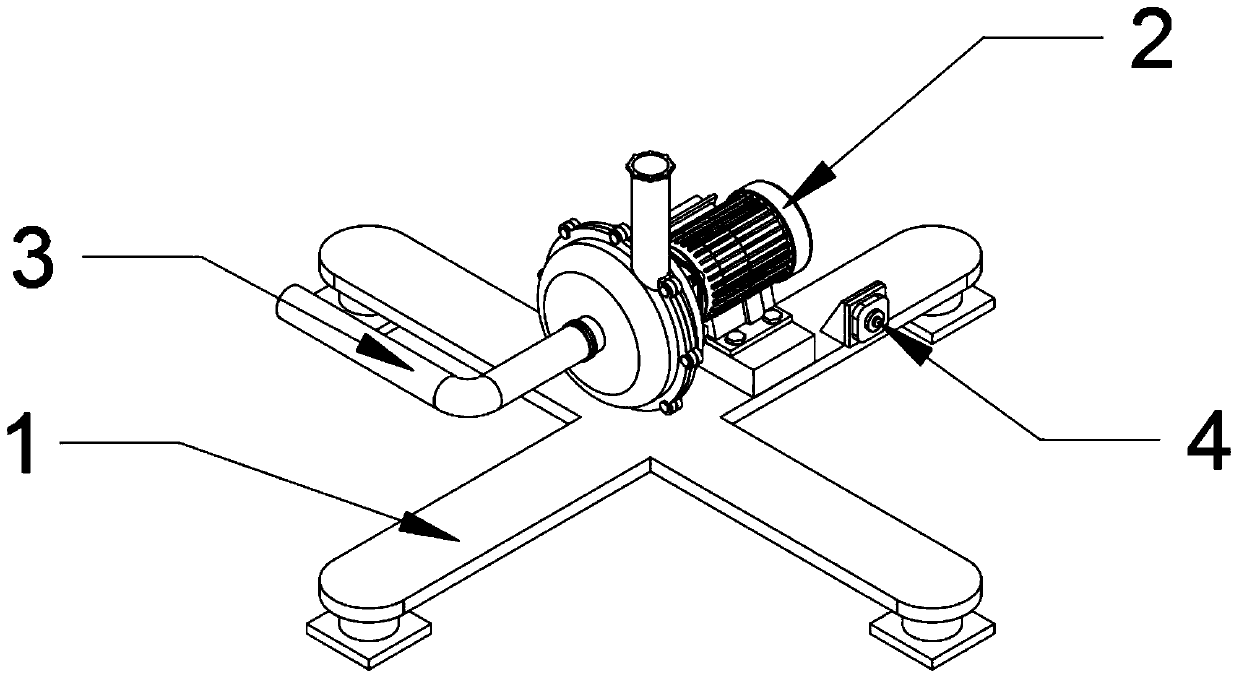

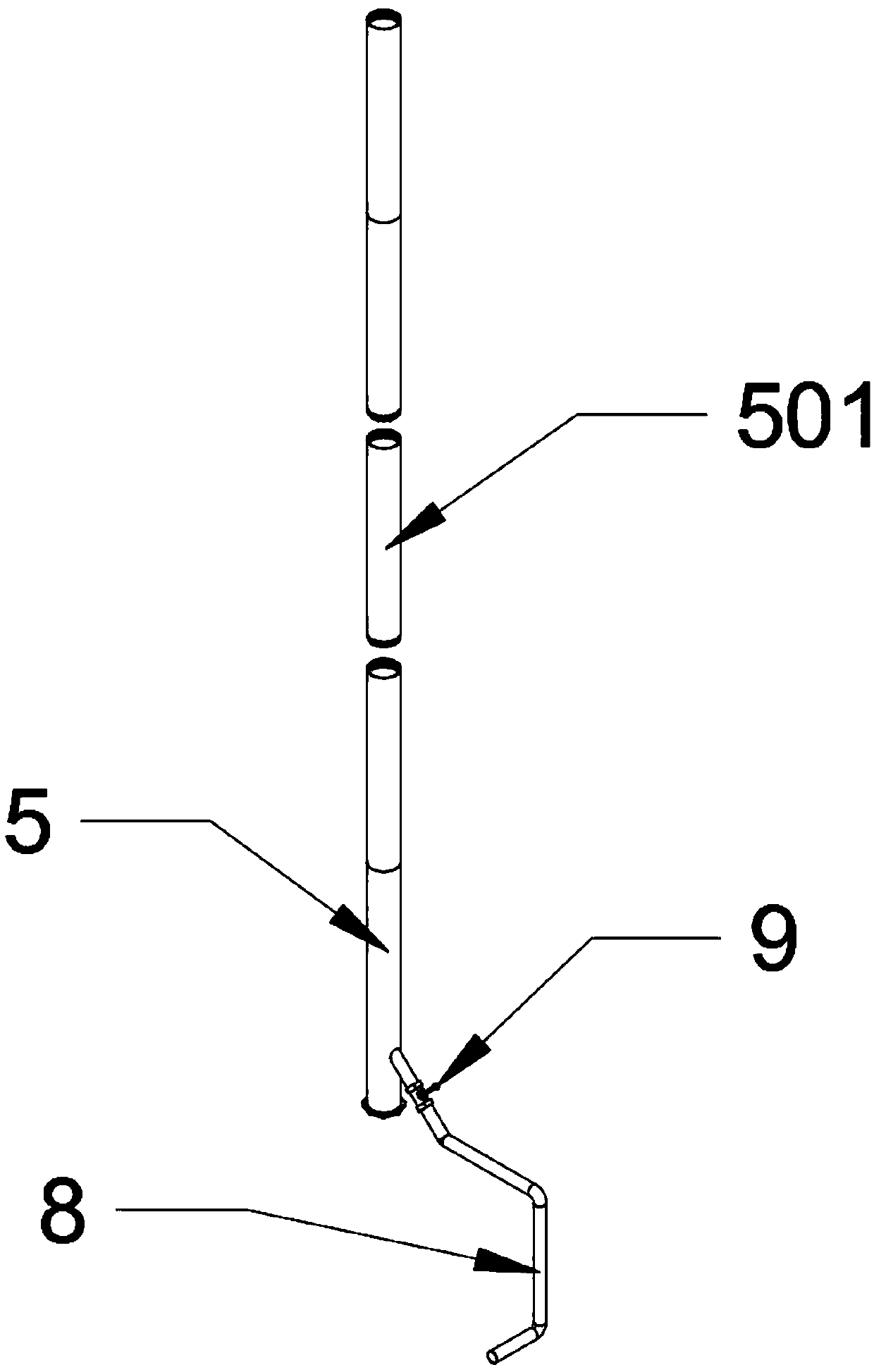

[0023] as attached figure 1 to attach Figure 4 Shown:

[0024] The invention provides an installed feeding device based on a spiral chute, which includes a machine base 1, an ore extraction pump 2, an extraction pipe 3, a control switch 4, an ore conveying pipe 5, a connecting pipe 501, a discharge chute 6, an Feed port 601, water retaining plate 7, bristles 701, water supply pipe 8 and control valve 9; the bottom of the ore extraction pump 2 is installed on the top end surface of the machine base 1 through bolts, and an extraction end of the ore extraction pump 2 is installed Pipe 3; the ore extraction pump 2 is connected to the control switch 4 through the power line, and the control switch 4 is installed on the top end surface of the machine base 1, and the control switch 4 is connected to the external power supply line through the power line; the ore conveying pipe 5 is a hollow pipe structure, and the ore delivery pipe 5 is installed on the top of the ore extraction pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com