Paying-off machine safety device

A safety device and pay-off technology, which is used in transportation and packaging, transportation of filamentous materials, and processing of thin materials, etc., can solve the problems of easy curling, low safety, knotting, etc., so as to reduce curling and protect production. Safety and damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

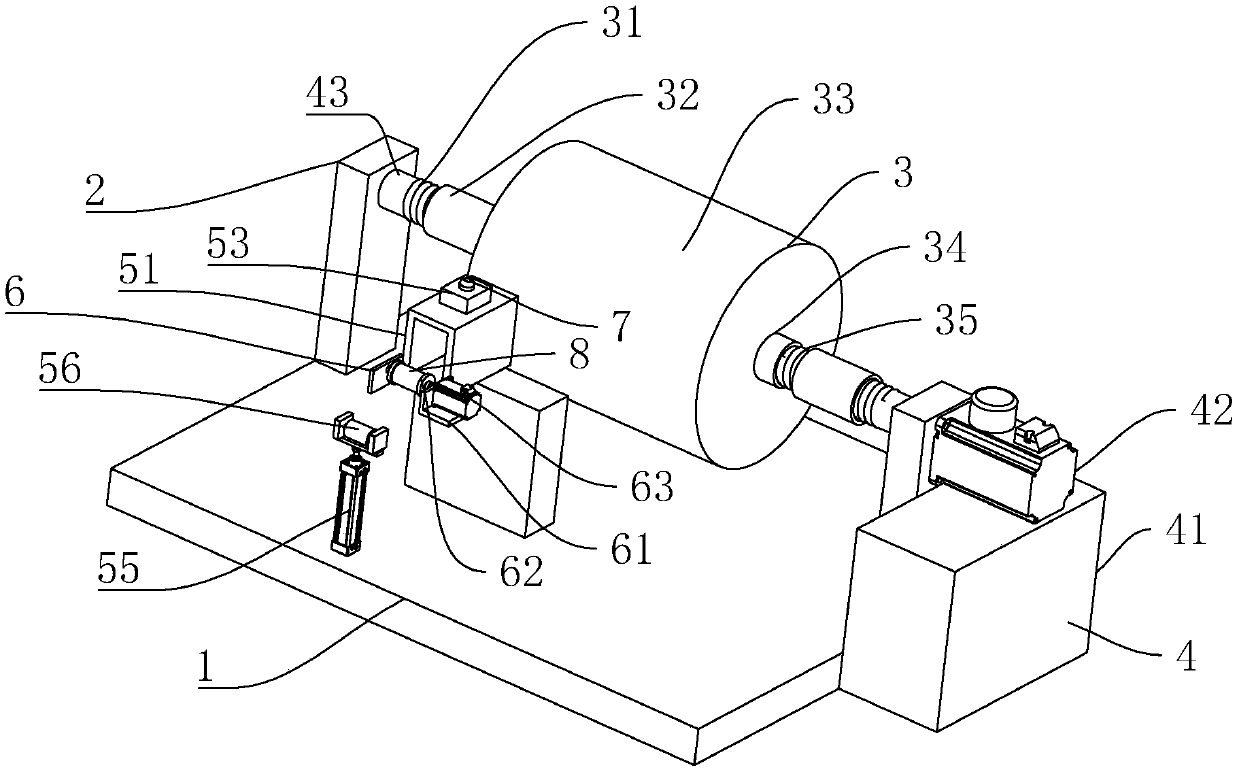

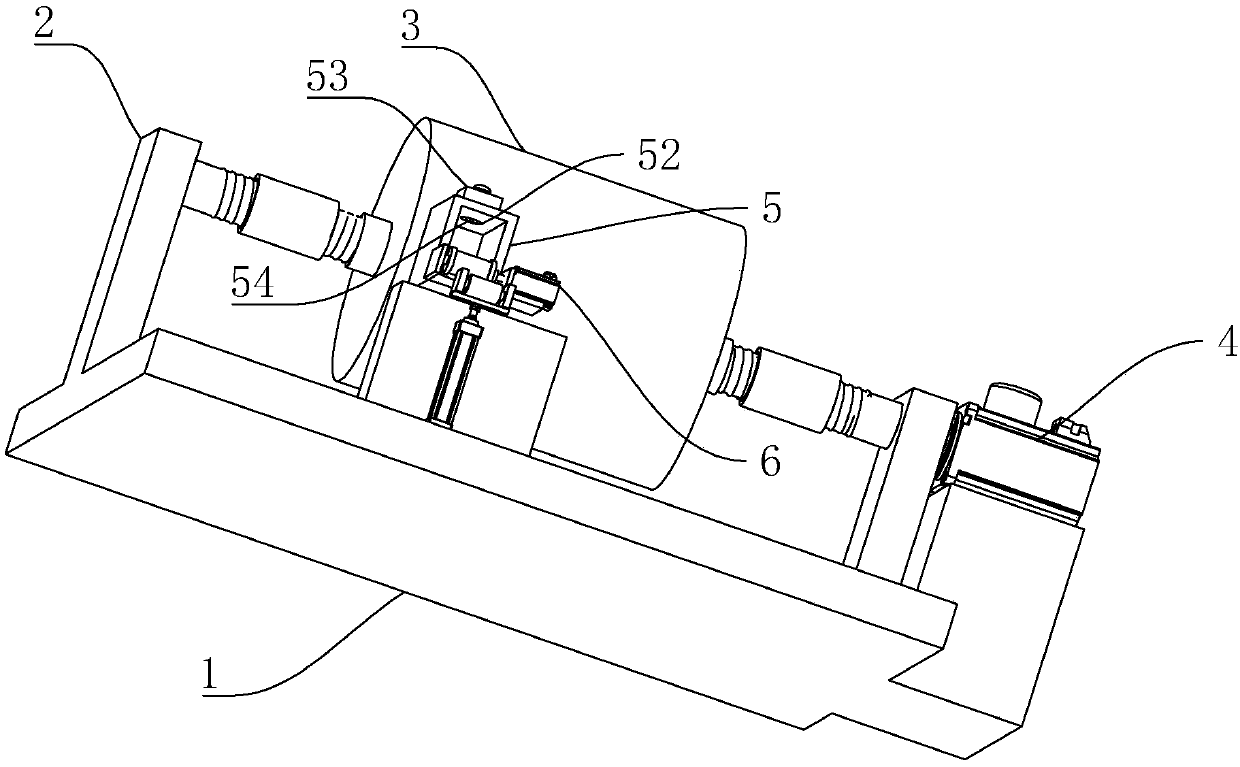

[0026] Embodiment 1: A safety device for a power pay-off machine, such as figure 1 and figure 2 As shown, it includes a base 1, and supports 2 are provided on both sides of the base 1, and a winding device 3 is provided on the support 2, and a power device 4 connected with the winding device 3 is also provided on the support 2. The outlet of the winding device 3 is provided with a locking device 5, and the locking device 5 includes a threading pipe 51 connected to the winding device 3 at the outlet end of the winding device 3. The top of the threading pipe 51 is provided with a through hole 52, and a 52 is provided with a controller 53 connected to the power unit 4 on the upper side of the 52, and an alarm 7 is also connected to the controller 53, and a control button 54 connected to the controller 53 is provided in the through hole 52 simultaneously, below the outlet end of the threading pipe 51. A lift cylinder 55 electrically connected to the controller 53 is provided, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com