Frost damage prevention light platform structure

A technology for light platforms and permafrost, applied in infrastructure engineering, protection devices, buildings, etc., can solve problems such as loss of engineering costs, large amount of engineering, etc., and achieve the effect of prolonging service life, saving maintenance and reinforcement or reconstruction funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

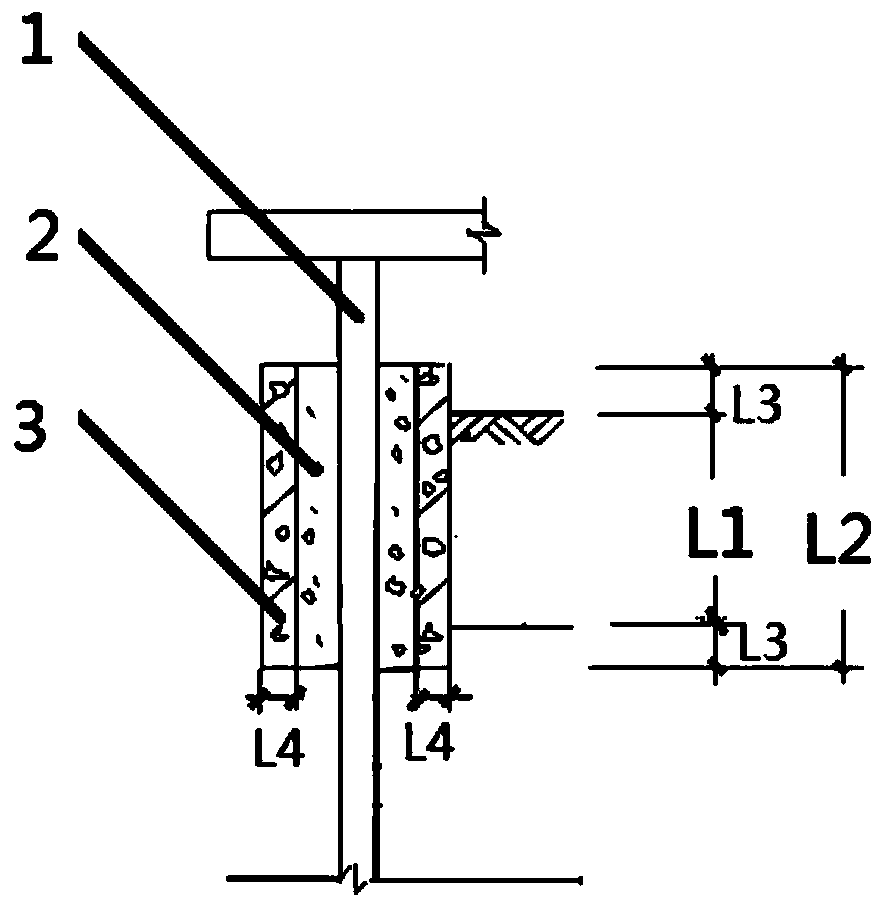

[0009] refer to figure 1 , the specific embodiment of the present invention is to install prefabricated reinforced concrete sleeve 3 around the light platform foundation pile body 1, there is a gap between the sleeve 3 and the light platform foundation pile body 1, and fine pebbles 2 are filled in the gap. The upper end surface of the sleeve is higher than the upper limit of the frozen soil layer, and the lower end surface of the sleeve is lower than the lower limit of the frozen soil layer. If the frozen soil layer L1 is 1700 mm, the sleeve L2 is 2500 mm, and the upper end surface of the sleeve is 400 mm higher than the upper limit L3 of the frozen soil layer, and the lower end surface of the sleeve is also 400 mm lower than the lower limit of the frozen soil layer. The wall thickness L4 of the cylinder is 60 mm.

[0010] Construction process of the present invention:

[0011] 1. After the piling of the light platform foundation pile is completed, excavate the soil around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com