A method for hoisting shield machine in a narrow space near the business line

A narrow space, shield machine technology, used in earth-moving drilling, mining equipment, tunnels and other directions, can solve the problems of reducing safety risks, difficult separation of cutter head and front shield, etc., to reduce safety risks, avoid difficult fixing and easy loss. Stable and easy to promote and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

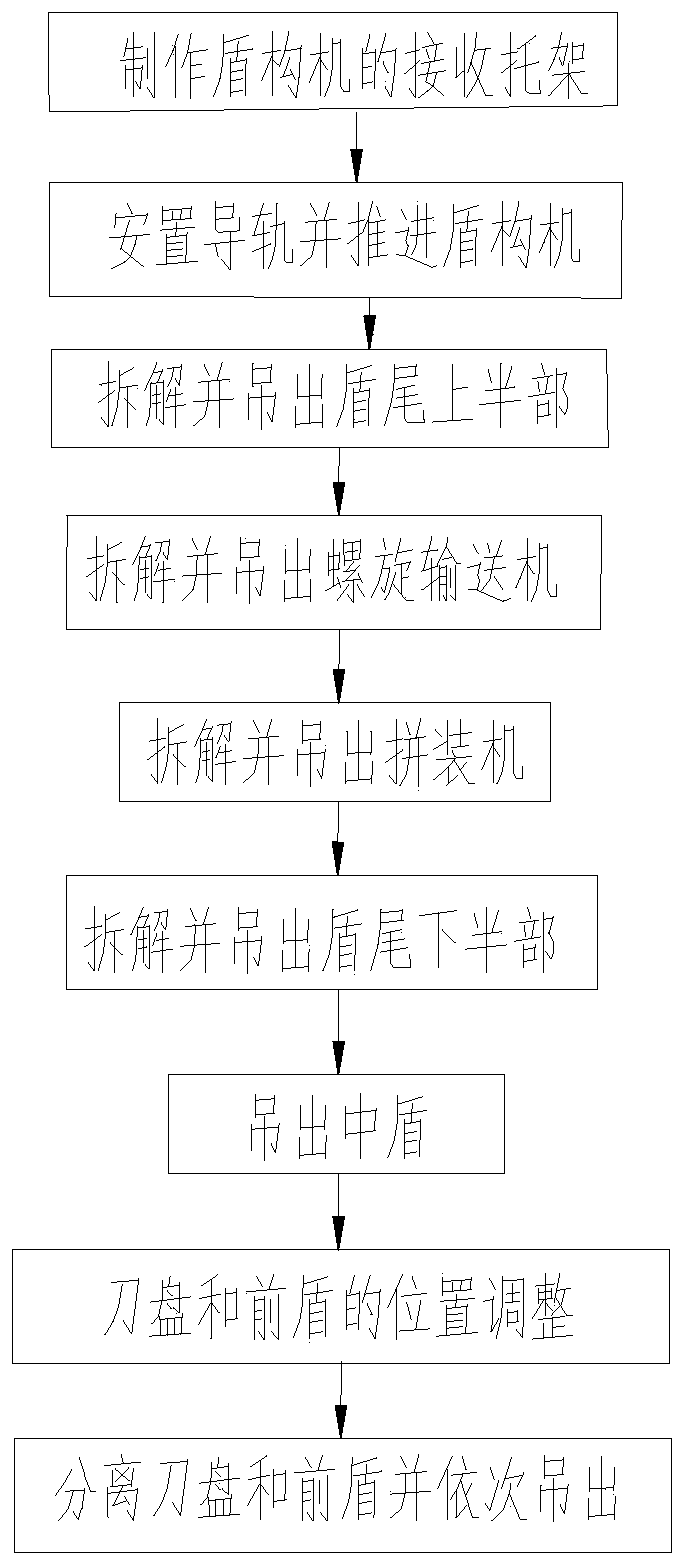

[0045] Such as Figure 1 to Figure 10 A method for hoisting a shield machine in a narrow space near the business line is shown, including the following steps:

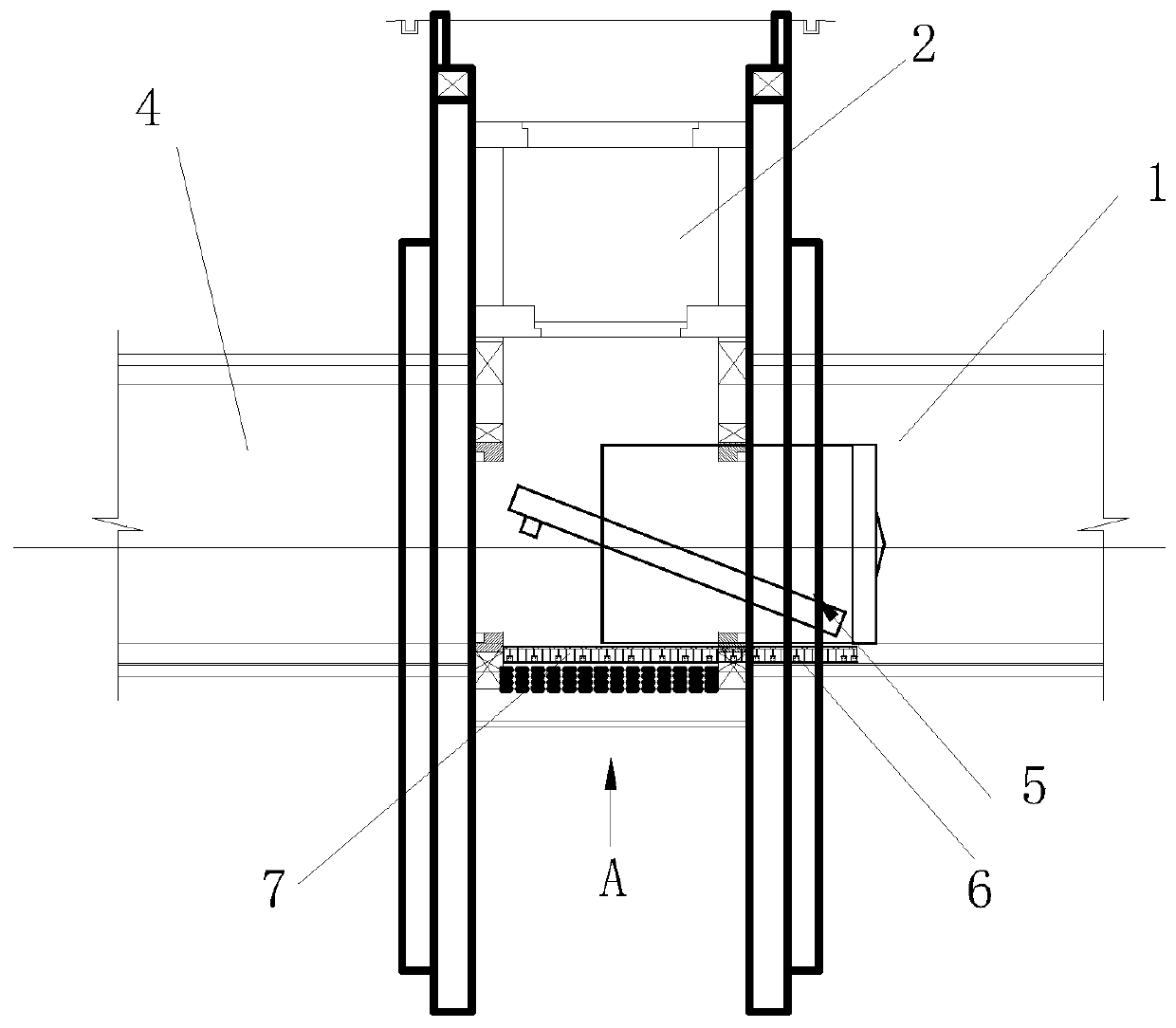

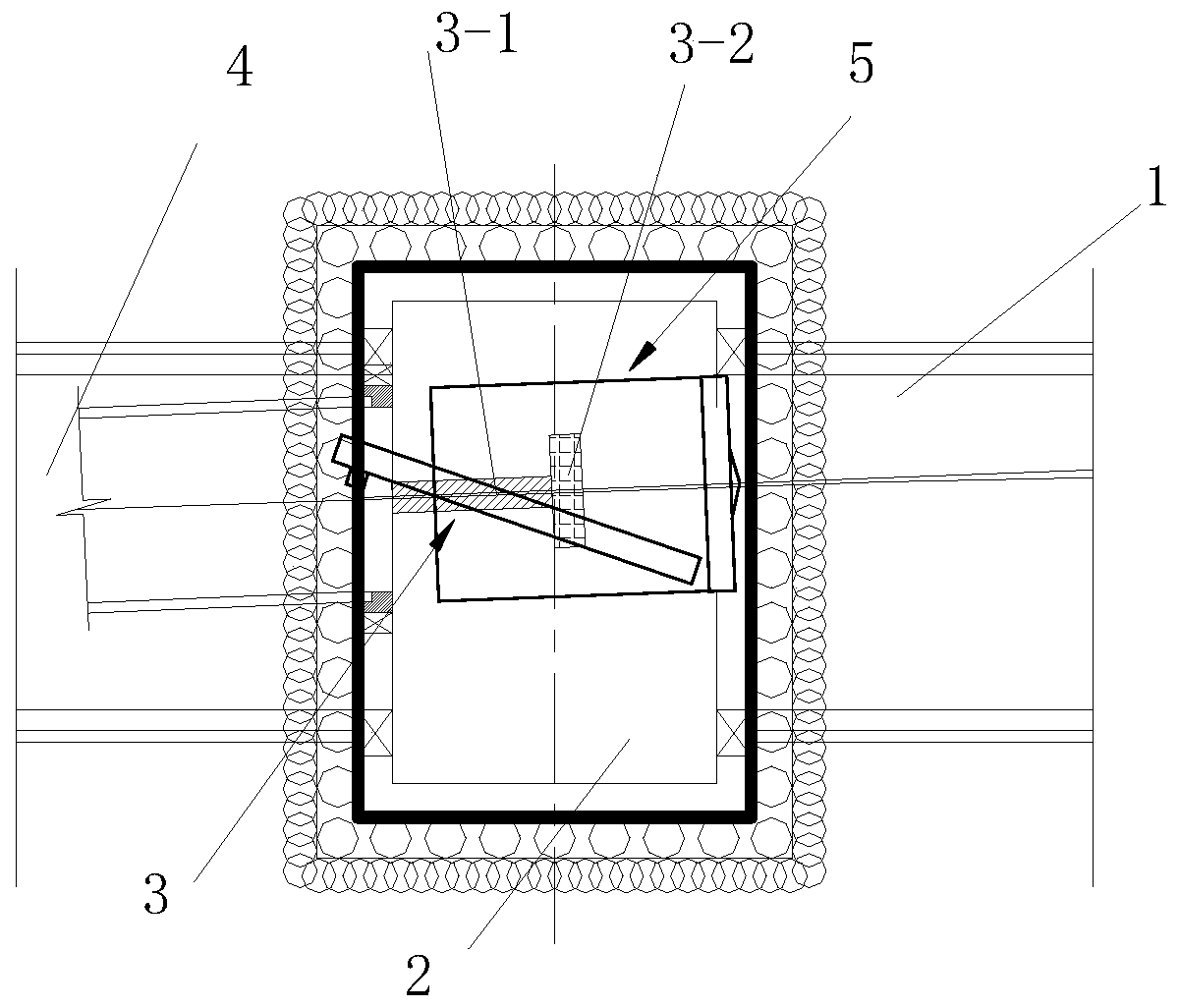

[0046] Step 1. Make the receiving bracket of the shield machine: After the construction of the shield tunnel 4 is completed, remove the unremoved temporary support in the buried tunnel 1, and make a concealed support on the second lining at the bottom of the tunnel 1 opening. Excavate the arc-shaped guide platform 6, connect the wellhead arc-shaped guide platform 7 in the vertical shaft 2 with the underground excavation arc-shaped guide platform 6 as a whole, and the wellhead arc-shaped guide platform 7 and the underground excavation arc-shaped guide platform 6 form the shield machine 5 Receive the bracket, and reserve a T-shaped slot 3 on the wellhead arc-shaped guide platform 7; the T-shaped slot 3 includes a first straight slot 3-1 and a The second straight groove 3-2;

[0047] Such as figure 2 As shown, step 2, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com