Delay firing mechanism utilizing low overload

A firing mechanism and firing pin technology, applied in the field of aviation lifesaving, can solve the problems of heavy weight, complex seat system structure, lack of delayed firing function, etc., and achieve the effect of solving the problem of heavy weight and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

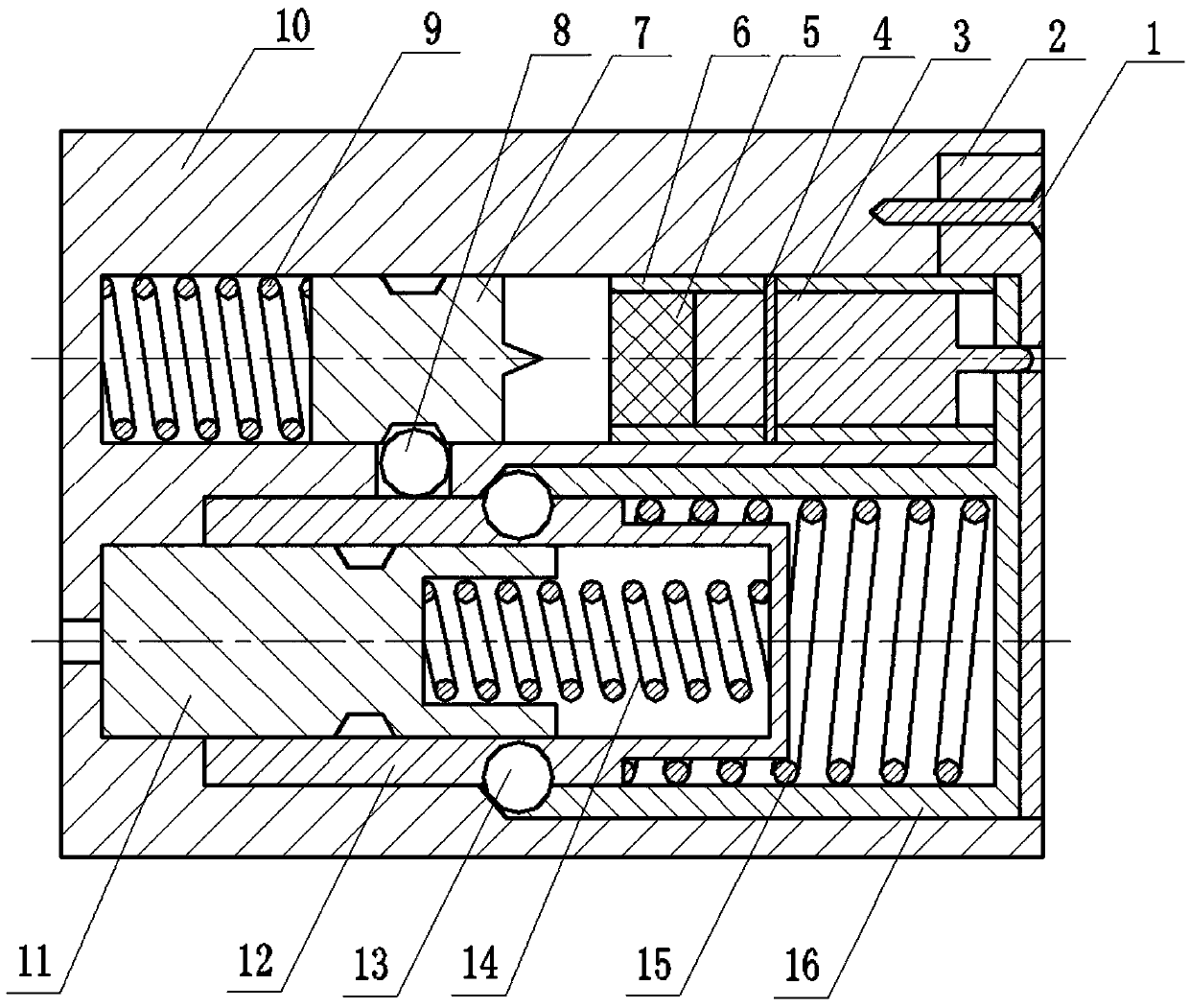

[0012] Below in conjunction with accompanying drawing the present invention is described in detail, see figure 1 . A time-delay firing mechanism utilizing low overload, comprising a fixing screw 1, a cover plate 2, a striker 3, a shear pin 4, an acupuncture detonator 5, a striker sleeve 6, a striker 7, a small steel ball 8, a striker spring 9, Housing 10, mass block 11, sleeve 12, large steel ball 13, mass block spring 14, sleeve spring 15 and mounting seat 16, the housing 10 is cylindrical and has two parallel cavities up and down. The firing pin spring 9, firing pin 7 and firing pin sleeve 6 are successively installed in the cavity above 10, and three small steel balls 8 are fixed through the annular groove on the firing pin 7, and the needle detonator 5 and firing pin are installed in the firing pin sleeve 6. 3. The striker sleeve 6 and the acupuncture detonator 5 are fixed by epoxy resin, the striker sleeve 6 and the inner cavity of the housing 10 are fixed by interferenc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap