An active scanning and receiving high-resolution pulsed ultrasound-acoustic emission detection method

A technology of acoustic emission detection and pulsed ultrasound, which is applied in the fields of material analysis using acoustic wave emission technology, solid analysis using sound wave/ultrasonic wave/infrasonic wave, material analysis using sound wave/ultrasonic wave/infrasonic wave, etc. It can solve the problem of difficult to achieve high-resolution scanning Problems such as imaging detection, low-resolution defect detection ability, large thickness and pore detection difficulties, etc., to achieve the effect of automatic scanning detection and imaging analysis, easy automatic scanning detection, and insensitive defect orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

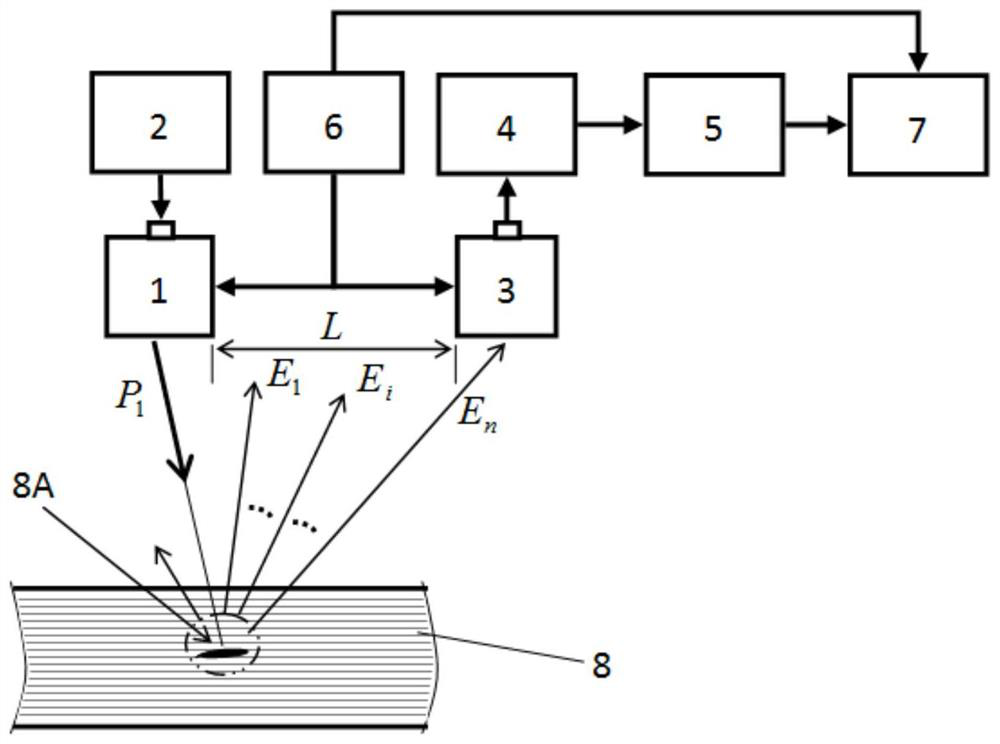

[0059] Using an active scanning and receiving type high-resolution pulsed ultrasonic-acoustic emission detection method and detection steps in the present invention, manual scanning and automatic scanning methods are selected, and the transmitting transducer 1 and receiving transducer 3 are made of AVIC composite materials. The AU-1 series transducer and CUS-21J produced by the responsible company are used as a scanning detection system, which are located on the same side of the part to be tested. Different frequency combinations of 2MHz, 5MHz, and 10MHz are selected, and the transmitting transducer 1 and receiving transducer 3 are used. The combination of the combination realizes the auxiliary scanning, and then realizes the active scanning and receiving of the acoustic emission signal from the defect. The 5mm and 10mm thick carbon fiber composite parts, the 3mm thick silicon carbide composite material, and the 5mm and 12mm thick aluminum alloy friction stir welding parts are r...

Embodiment 2

[0061] Adopt an active scanning and receiving type high-resolution pulsed ultrasonic-acoustic emission detection method and detection steps in the present invention, select a dual-channel automatic scanning mode, and use the AVIC Composite Materials Co., Ltd. for the transmitting transducer 1 and receiving transducer 3 The AU-1 series transducers produced, MUI-21 and CUS-21J are used as scanning detection systems, and different frequency combinations of 1MHz, 2MHz, and 5MHz are selected to realize auxiliary scanning through the combination of transmitting transducer 1 and receiving transducer 3 , and then realize the active scanning and receiving of the acoustic emission signal from the defect. A series of actual detection applications have been carried out on 20mm and 50mm carbon fiber composite parts respectively. The application results show that the scanning imaging effect is very good, and the detection resolution and surface detection blind area can reach The thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com