Net rolling type easy-to-clean dedusting device

A technology of dust removal device and rolling net, which is applied in the direction of transportation and packaging, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of lower dust removal efficiency, filter blockage, filter air permeability reduction, etc., and achieve high dust removal efficiency, Easy to clean, easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is further described:

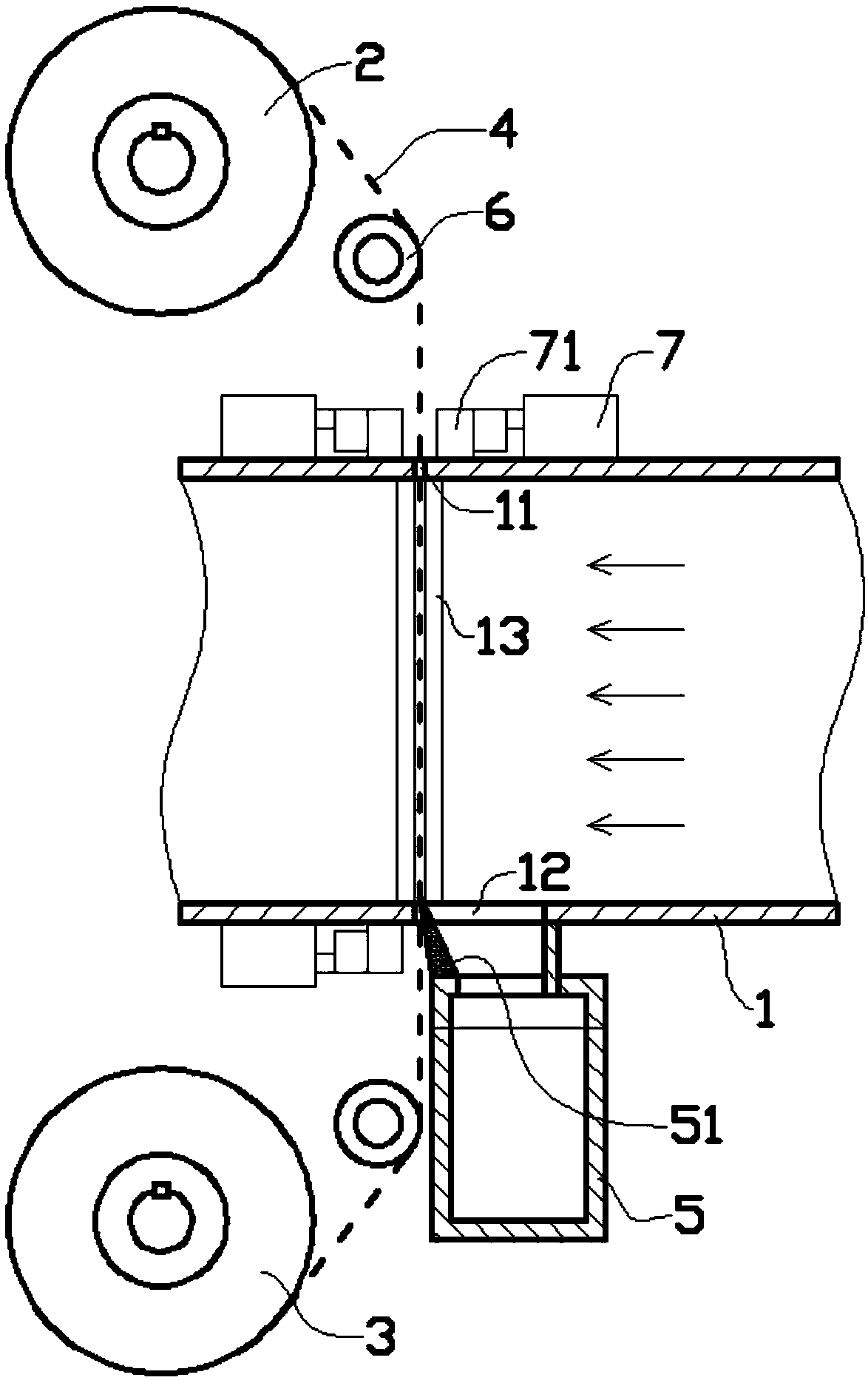

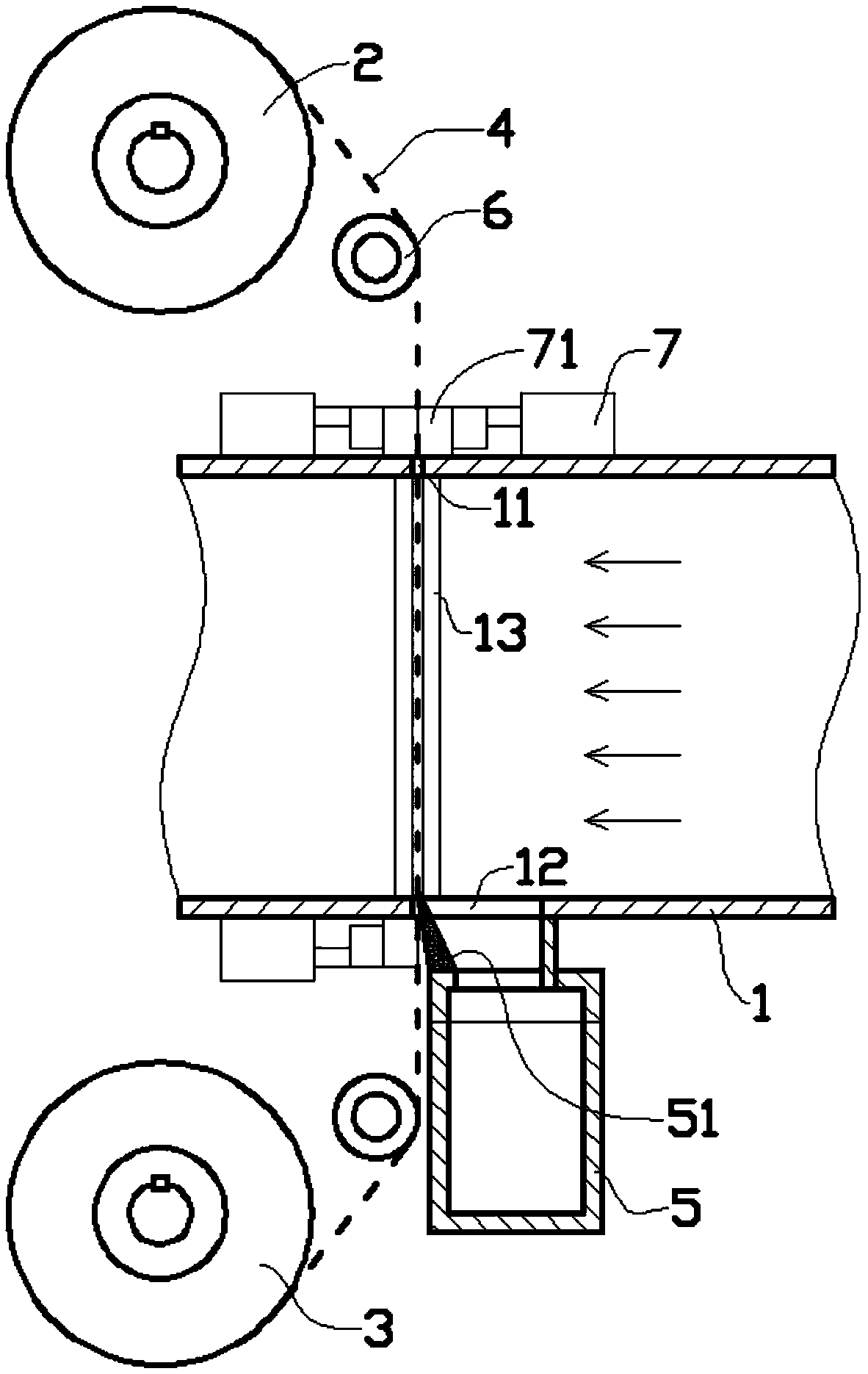

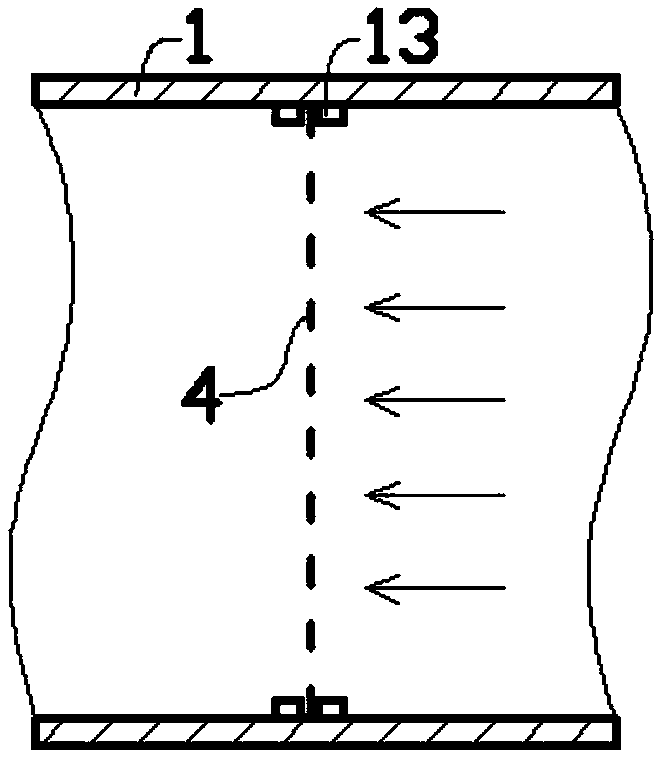

[0014] Such as figure 1 , figure 2 and image 3 As shown in the embodiment, in this embodiment, the roll net type easy-to-clean dust removal device includes a horizontal dust removal pipe 1, and the upper and lower sides of the dust removal pipe 1 are respectively equipped with a mesh roll 2 and a roll roll 3. A roll of filter screen 4 is wound on the screen roll 2, and the upper and lower sides of the dust removal pipe 1 are respectively processed with mesh grooves 11, and the filter screen 4 output from the screen roll 2 passes through the screen vertically from top to bottom. The net-passing groove 11 of the dust removal pipe 1 is coiled on the net roll 3, and the net roll 3 is connected with the transmission structure, and the transmission mechanism can drive the net roll 3 to rotate, and the filter screen 4 is carried out. Coiling; the side of the net passing groove 11 at the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com