Peanut grading machine

A classifier and peanut technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of large energy consumption, large space occupation, difficult to clean, etc., and achieve the effect of small occupied volume, accurate classification, and difficult to grading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

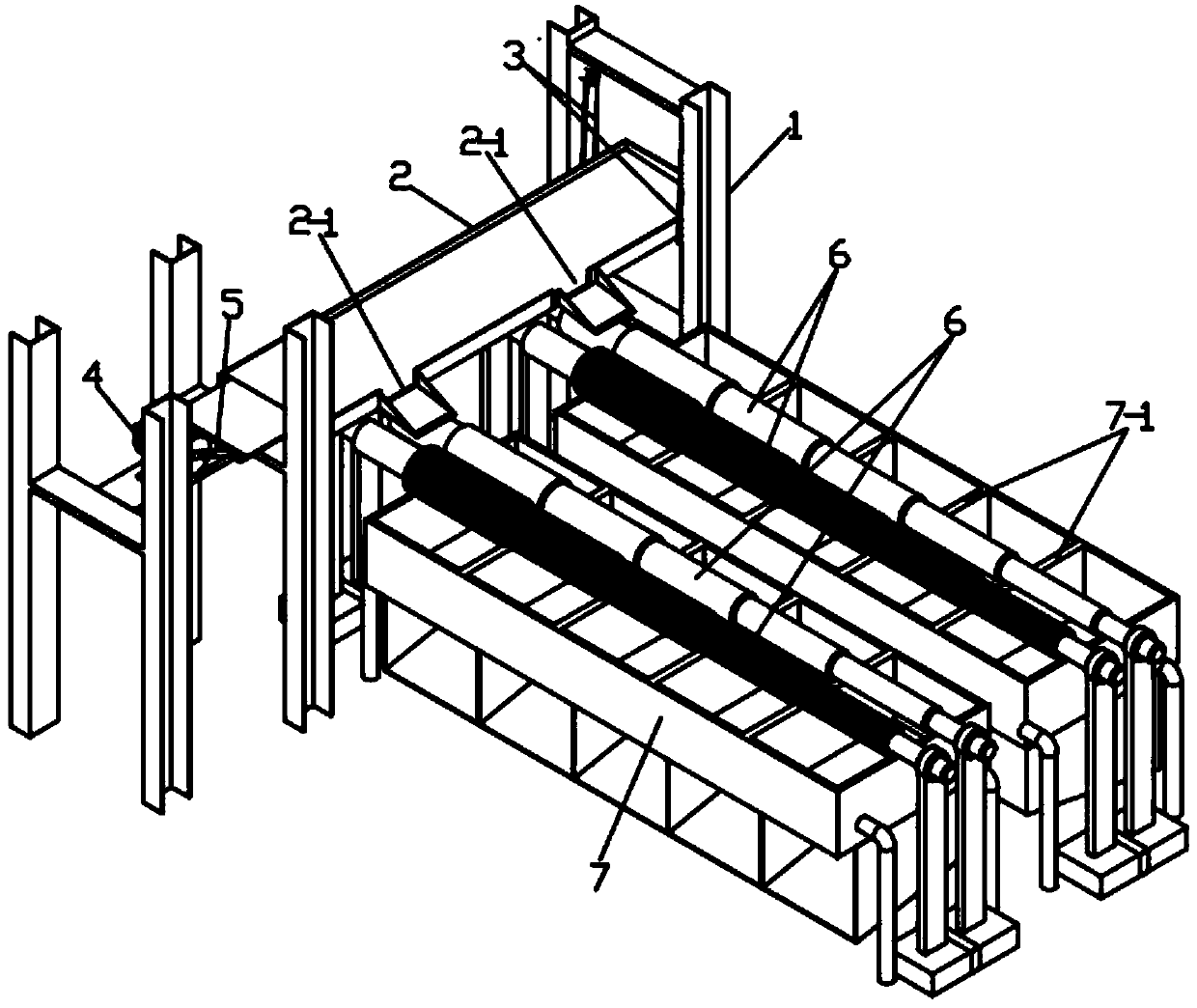

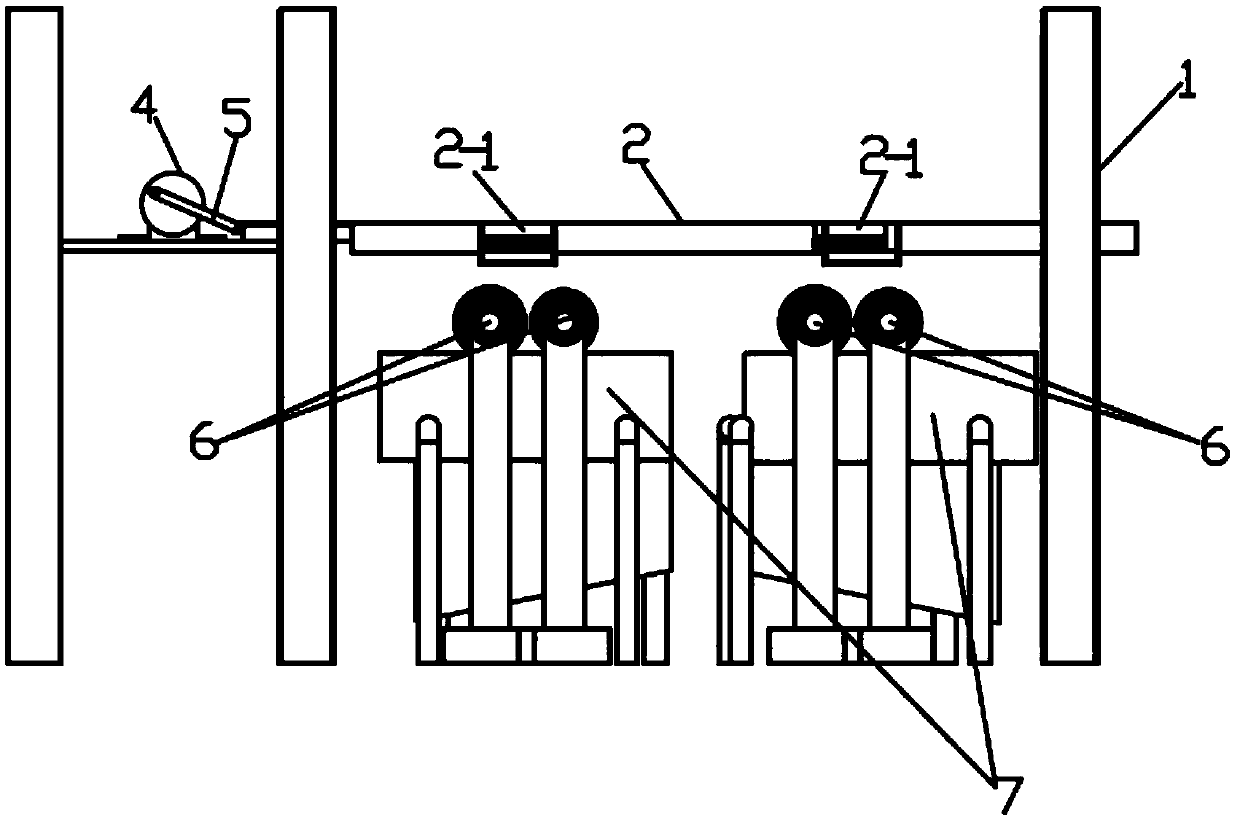

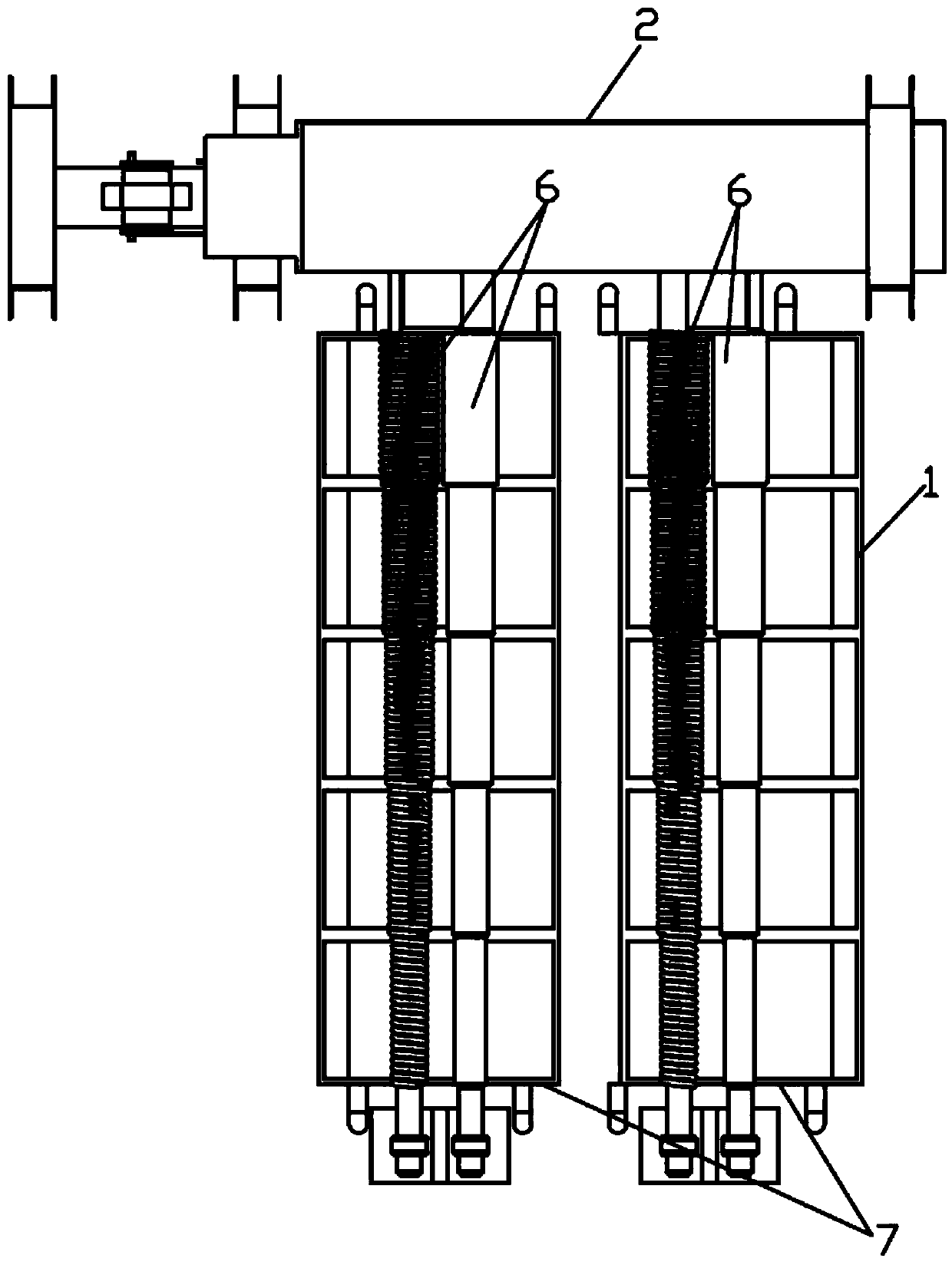

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] Depend on Figure 1-4 As can be seen from the illustrated embodiment, the present embodiment includes a frame 1, a peanut feeding device, a peanut grading device and a peanut collecting device, and the peanut feeding device includes a feeding trough 2, a boom 3 and a driving structure, and the lower end of the boom 3 Connect with the right end of feeding chute 2 through rotating shaft, the upper end of boom 3 is connected with frame 1 through rotating shaft, so that the right end of feeding chute 2 is hung on the frame, the driving structure includes feeding chute drive motor 4 and rocker Arm 5, feeding chute driving motor 4 are hinged with the left end of feeding chute 2 through rocker arm 5, so that feeding chute 2 swings left and right, and more than one discharge port 2-1 is provided on the rear side wall of feeding chute 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com