A fully automatic uncoiler with feeding and speed control functions

A fully automatic, uncoiler technology, used in manufacturing tools, metal processing equipment, metal processing, etc., can solve problems such as high cost and complex structure, and achieve the effect of convenient maintenance, convenient operation and cost reduction in the later period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

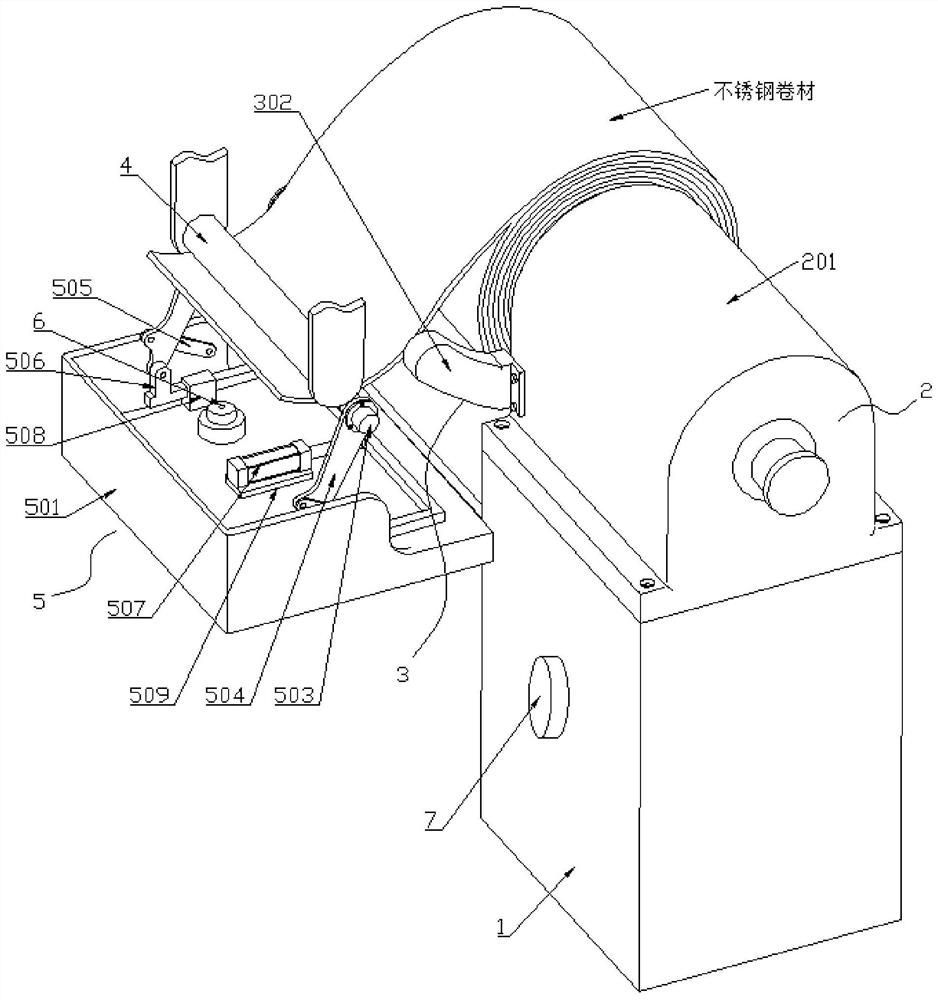

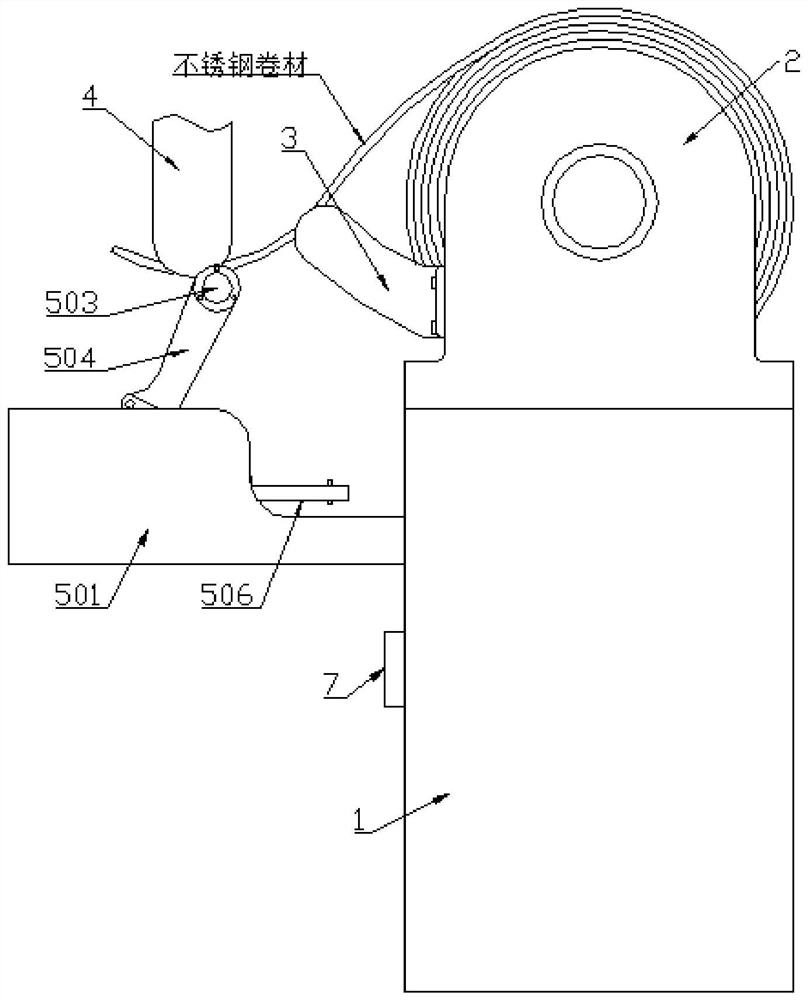

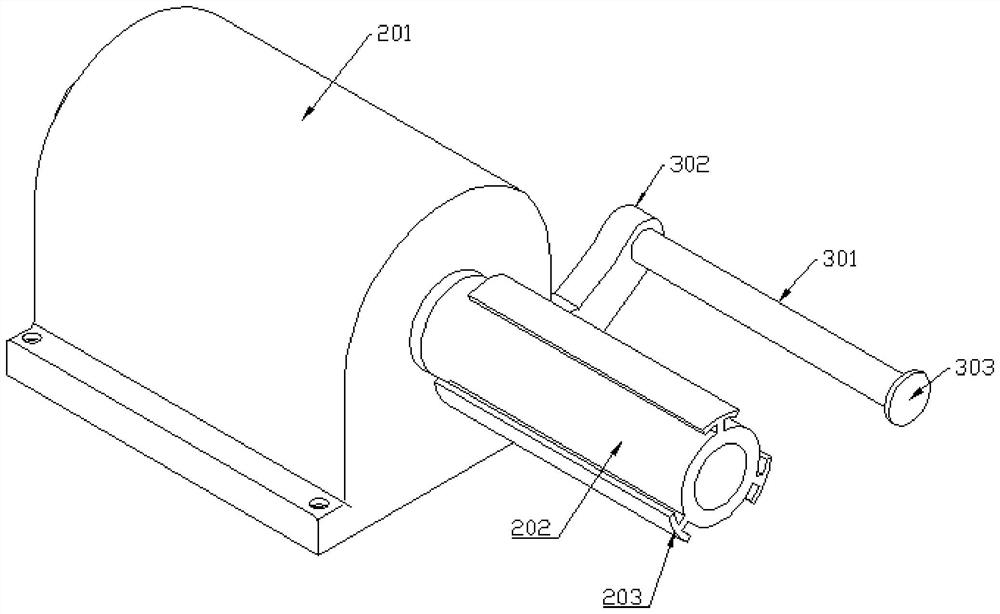

[0025] Such as Figure 1 to Figure 4 As shown, a fully automatic uncoiler with feeding and speed control functions, including a machine base 1, a power device 2, a support assembly 3, a tension roller 4, an ultrasonic sensor 6 and a speed control device 5, the power The device 2 is installed on the machine base 1, the support assembly 3 is installed on the side of the power device 2 and supports the stainless steel coil, and the tension roller 4 is located above the stainless steel coil and downstream of the support assembly 3 end (that is, the feeding direction of the stainless steel coil);

[0026] The speed control device 5 includes a tray 501, a speed control roller shaft 502, a servo motor 503, a side plate 504, a linkage plate 505, a guide rod 506 and a linear drive device 507, and the tray 501 is installed on the base 1 through an L-shaped bracket. and located below the tension roller 4, the speed control roller shaft 502 is rotatably connected between the two side pla...

Embodiment 2

[0032] as attached Figure 4 As shown, a fully automatic uncoiler with feeding and speed control functions, including a machine base 1, a power device 2, a support assembly 3, a tension roller 4, an ultrasonic sensor 6 and a speed control device 5, the power The device 2 is installed on the machine base 1, the support assembly 3 is installed on the side of the power device 2 and supports the stainless steel coil, and the tension roller 4 is located above the stainless steel coil and downstream of the support assembly 3 end (that is, the feeding direction of the stainless steel coil);

[0033] The speed control device 5 includes a tray 501, a speed control roller shaft 502, a servo motor 503, a side plate 504, a linkage plate 505, a guide rod 506 and a linear drive device 507, and the tray 501 is installed on the base 1 through an L-shaped bracket. and located below the tension roller 4, the speed control roller shaft 502 is rotatably connected between the two side plates 504 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com