Upsetting method of battery pole piece roller

A battery pole piece and roll technology, applied in the field of roll forging, can solve the problems of easy formation of rounded corners and lack of meat, difficulty in machining, low production efficiency, etc., and achieve the effects of reducing fire times, saving raw materials and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

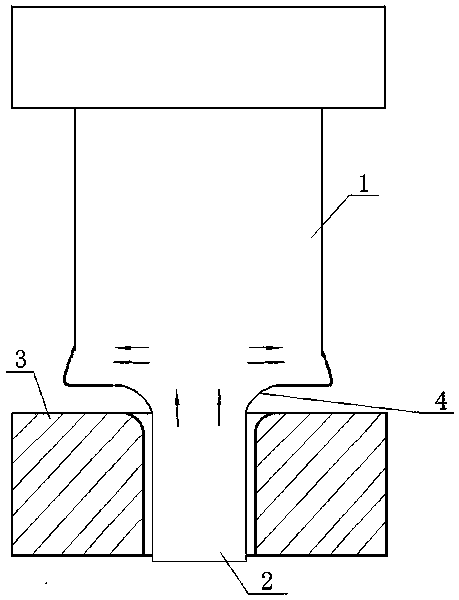

[0026] In this embodiment, the diameter of the roll body blank of the battery pole piece roll is 840 mm, and the diameter of the roll neck blank is 400 mm, which now needs to be upset. The diameter of the inner hole of the drain plate used is 400mm.

[0027] When unloading, a rounded-cornered residual material is reserved at the root of the roll body and the roll neck, and the radius of the residual material is 160mm. A spool is used for partial upsetting, and a protrusion is formed at the corner of the roller body, and the height of the protrusion is 20 mm. In the subsequent drawing process, the protrusion can be corrected to a right angle of the roller body.

[0028] This process only needs to increase the remaining material by 200Kg, while the original process needs to increase the roll body material by 520Kg. This process greatly saves raw materials.

Embodiment 2

[0030] In this embodiment, the blank diameter of the roll body of the battery pole piece roll is 790 mm, and the diameter of the roll neck blank is 370 mm, which now needs to be upset. The diameter of the inner hole of the drain plate used is 370mm.

[0031] When unloading, a rounded-cornered remnant is reserved at the root of the roll body and the roll neck, and the radius of the remnant is 92.5mm. A squeeze plate is used for partial upsetting, and a protrusion is formed at the corner of the roller body, and the height of the protrusion is 10 mm. In the subsequent drawing process, the protrusion can be corrected to a right angle of the roller body.

[0032] This process only needs to increase the remaining material by 180Kg, while the original process needs to increase the roll body material by 400 Kg. This process greatly saves raw materials.

Embodiment 3

[0034] In this embodiment, the diameter of the blank of the battery pole piece roll is 840 mm, and the diameter of the blank of the roll neck is 390 mm, which now needs to be upset. The diameter of the inner hole of the drain plate used is 400mm.

[0035] When unloading, a rounded corner-shaped residual material is reserved at the root of the roll body and the roll neck, and the radius of the residual material is 150mm. A squeeze plate is used for partial upsetting, and a protrusion is formed at the corner of the roller body, and the height of the protrusion is 15 mm. In the subsequent drawing process, the protrusion can be corrected to a right angle of the roller body.

[0036] This process only needs to increase the remaining material by 183Kg, while the original process needs to increase the roll body material by 500Kg. This process greatly saves raw materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com