Curved surface veneering process of solid wood furniture

A veneer and furniture technology, which is applied to wood processing appliances, manufacturing tools, and the joining of wooden veneers, can solve the problem of unsatisfactory veneer shape, seam flatness and density, and veneer dimensions that cannot be accurately unified , Inaccurate mold size and other problems, to achieve the effect of smooth and uniform skin coating, improve efficiency and skin coating efficiency, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

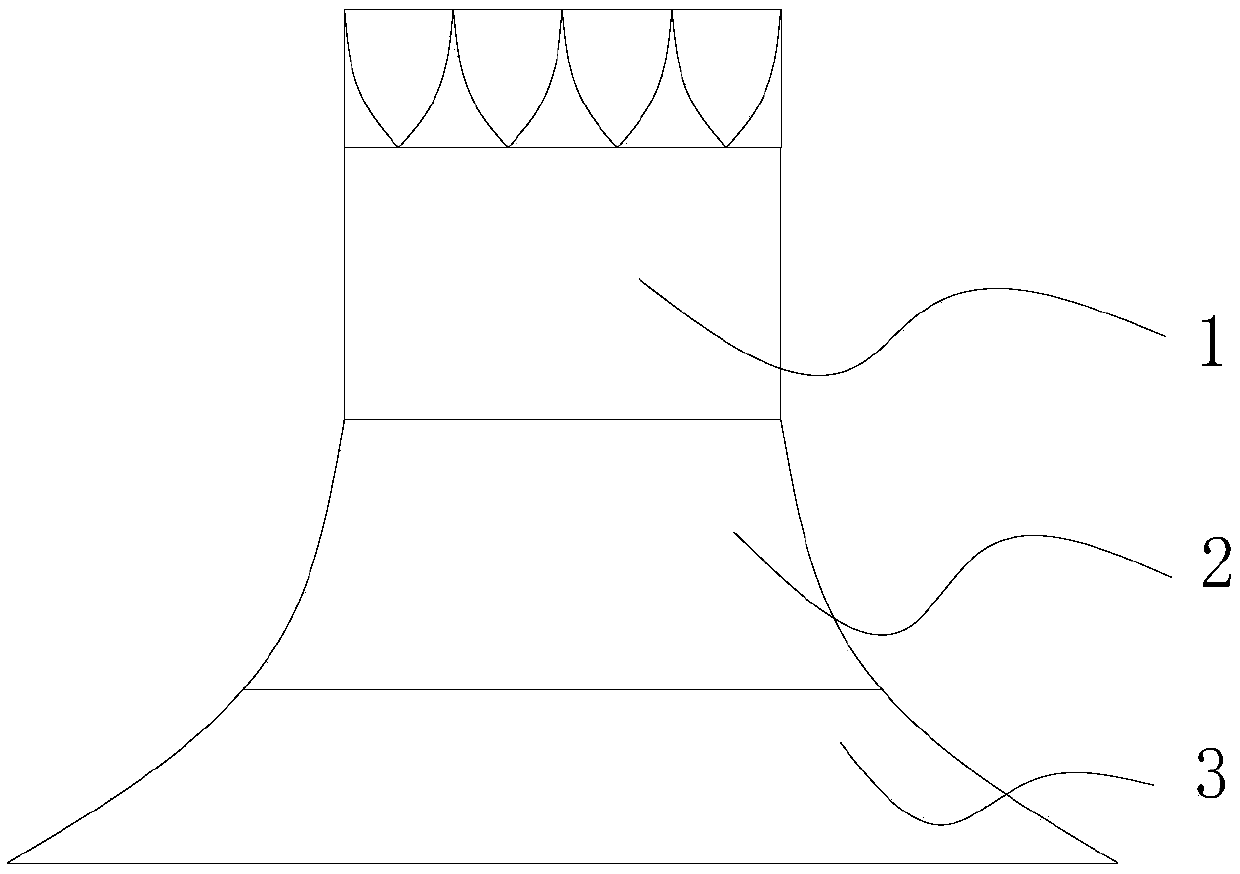

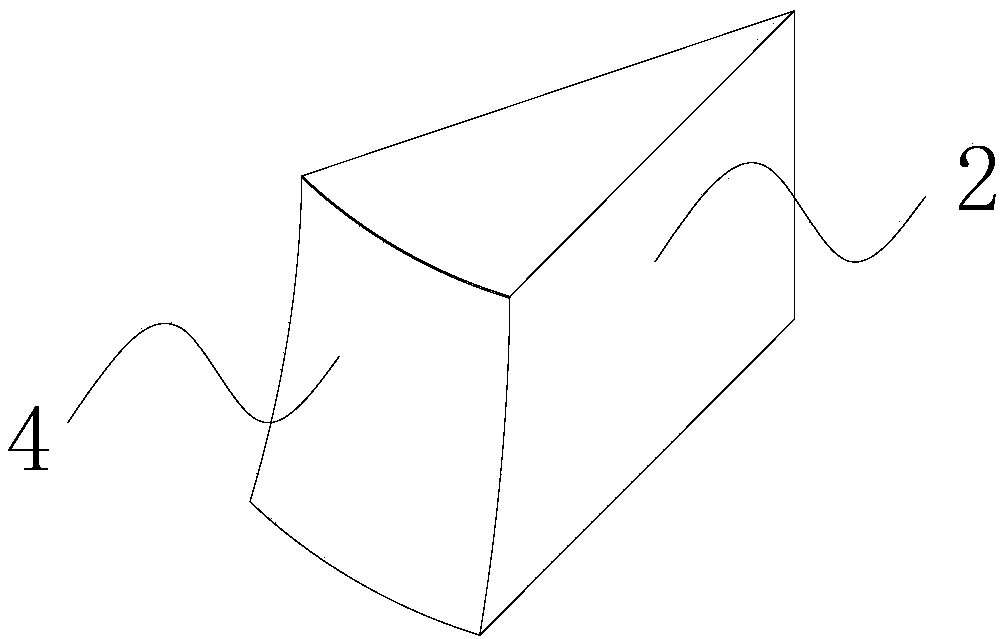

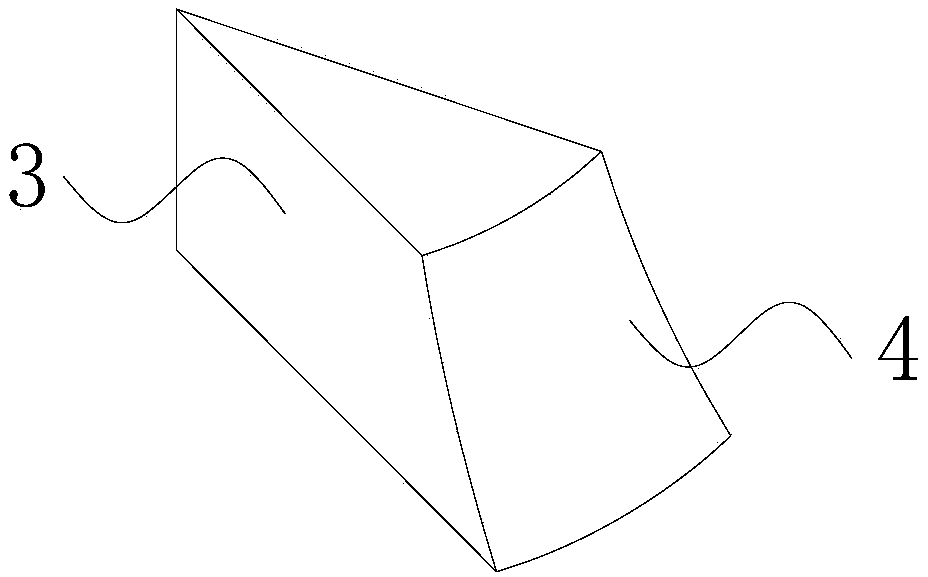

[0026] Example: Carry out skinning on the column of the corner table, a. According to the shape of the column, divide the lower half of the column into three parts, which are as follows from top to bottom: the first part 1 is a cylindrical structure, and the skinning is not difficult, no need Make the skin-mounting mold; the second part 2 and the third part 3 are curved surface structures, and the skinning is difficult, so it is necessary to make a skin-mounting mold. b. Use the three-dimensional modeling software SolidWorks to establish the curved surface solid models of the second part 2 and the third part 3 to be veneered 4 . c. Use a 3D printer to print the skin-applying molds containing the second part 2 and the third part 3 to be laminated 4 respectively. d. Divide the skinning molds of the second part 2 and the third part 3 into 10 equal skinning molds respectively. e. Take one skinning mold for the above-mentioned second part 2 and third part 3, and use the two equal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com