Ventilating dustbin

A technology of dustbins and ventilation holes, which is applied in the direction of dustbins, garbage collection, household appliances, etc., and can solve the problems of no deodorization function, complex structure of dustbins, and inability to play an environmental protection role.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

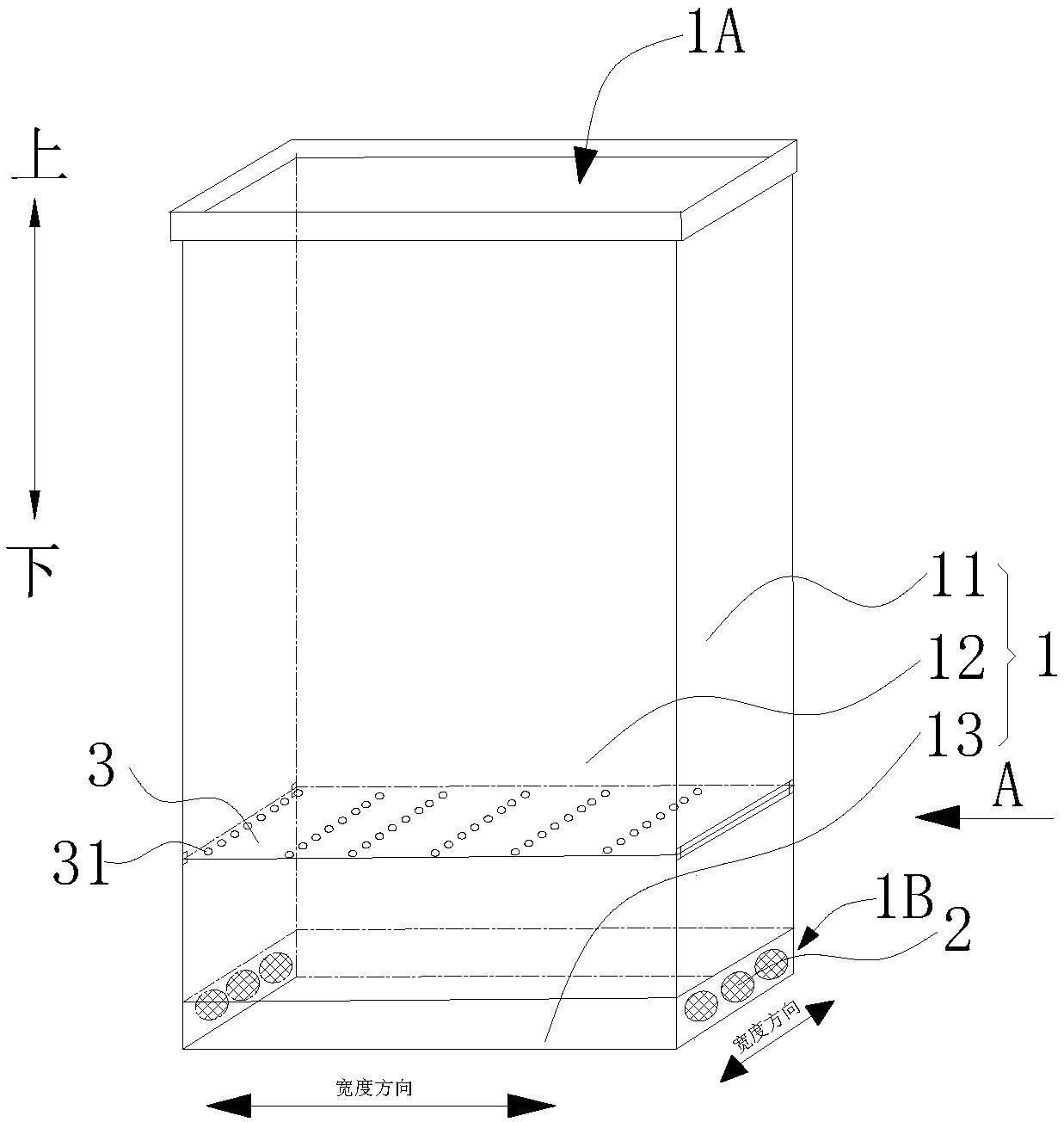

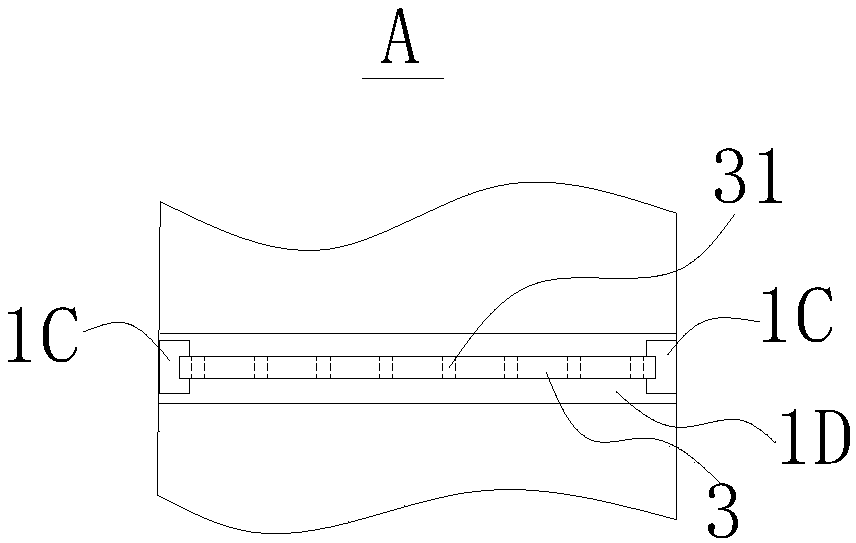

[0016] A ventilated dustbin according to the invention, such as figure 1 and figure 2 As shown, it includes: a box body 1, and the box body 1 includes a pair of oppositely arranged first side panels 11, a pair of oppositely arranged second side panels 12 and connecting the first side panels 11 and the second side panels. The bottom plate 13 of 12, and the first side plate 11, the second side plate 12 and the bottom plate 13 jointly define the accommodating chamber 1A, and its upper port is open, located on the first side plate 11 and / or the second side plate Ventilation holes 1B are provided on the two side plates 12 , and a partition 3 with mesh holes 31 is provided in the accommodating chamber 1A.

[0017] It can be understood that by arranging ventilation holes 1B on the first side plate 11 and / or the second side plate 12, the air circulation can be formed to enhance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com