Automatic feeding machine for spring compression extension detecting

A technology of automatic feeding and inspection, applied in the direction of vibrating conveyors, conveyors, conveyor objects, etc., can solve the problems of affecting the production and processing progress and low efficiency, and achieve the effect of improving production efficiency and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

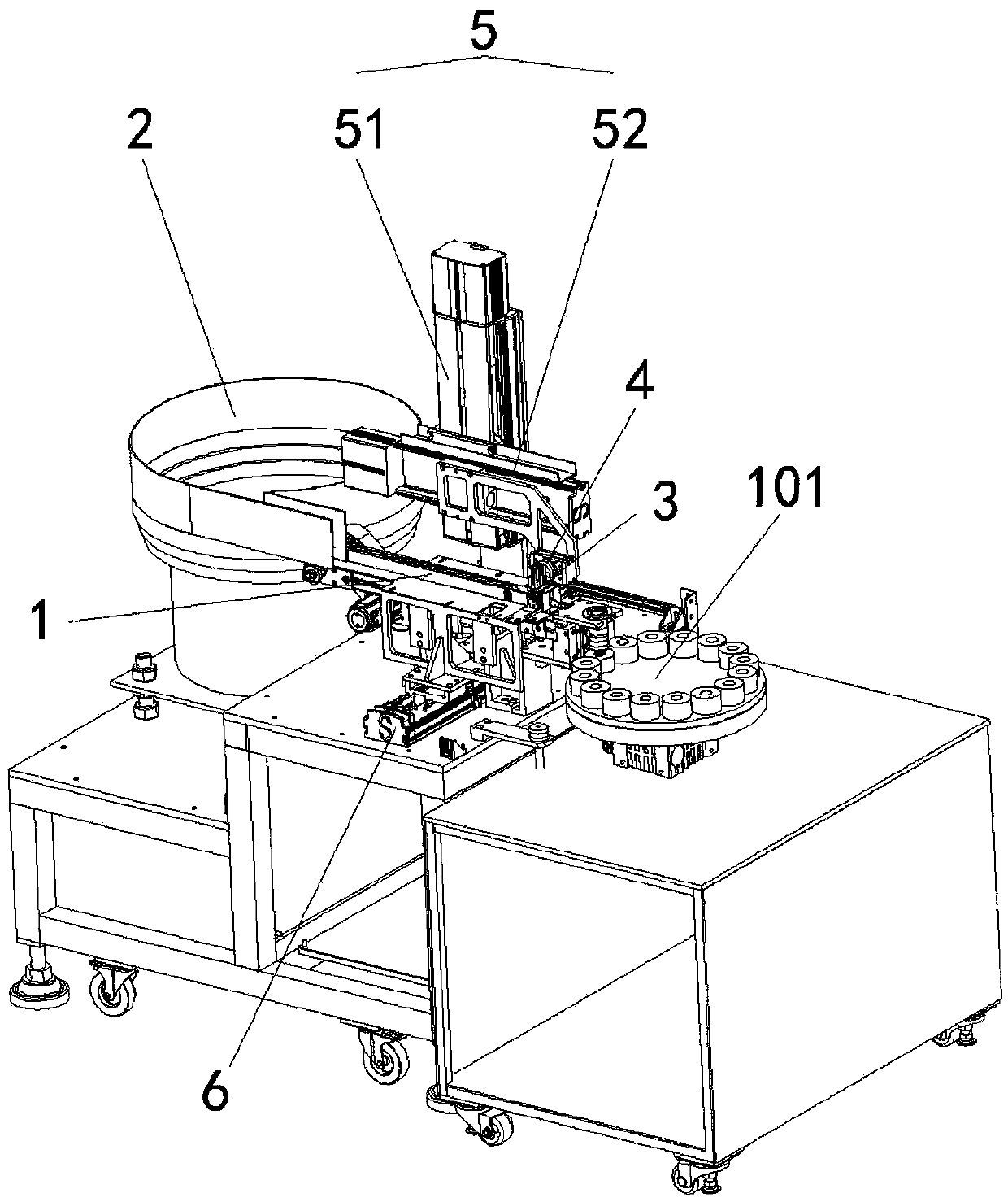

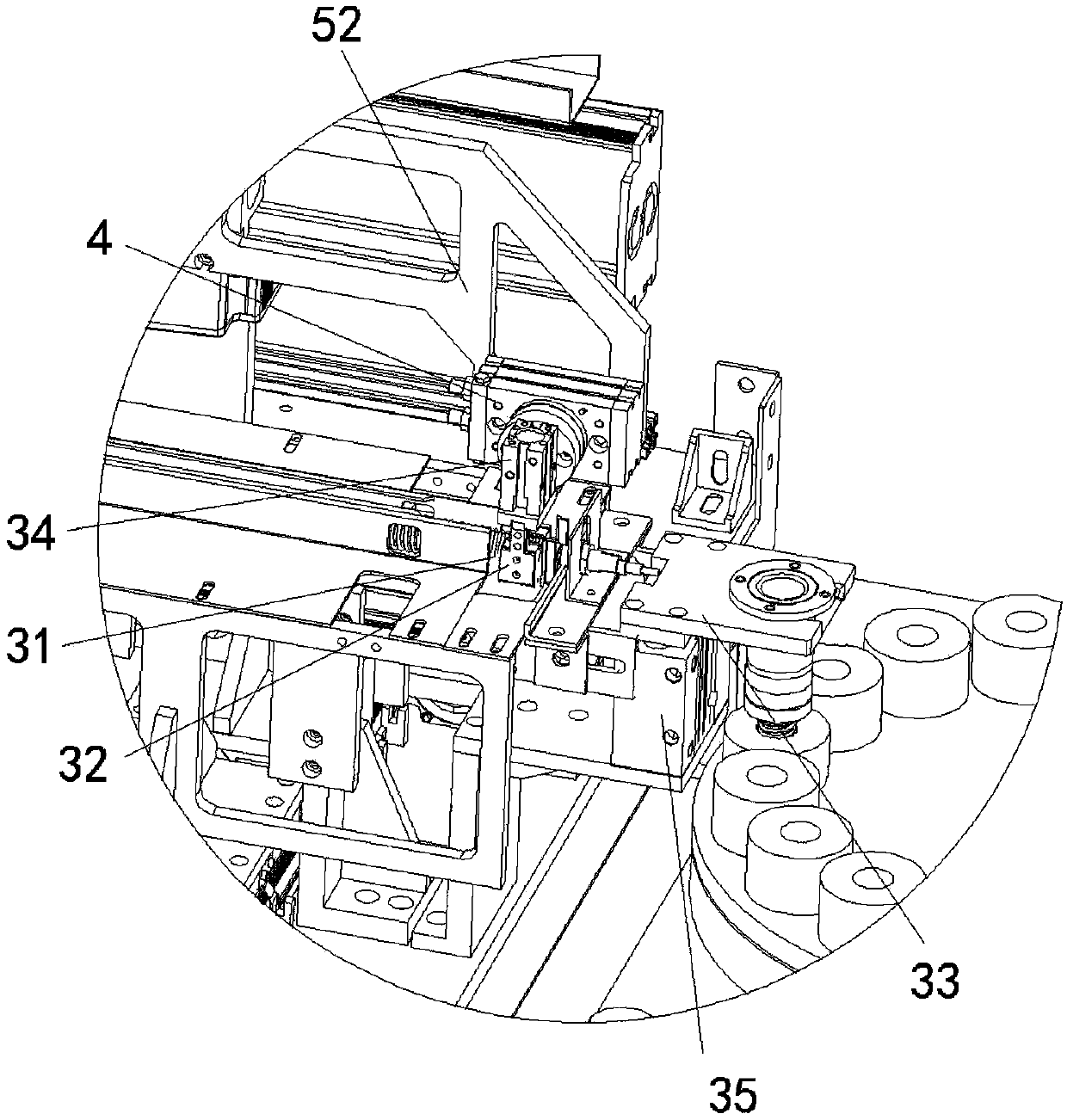

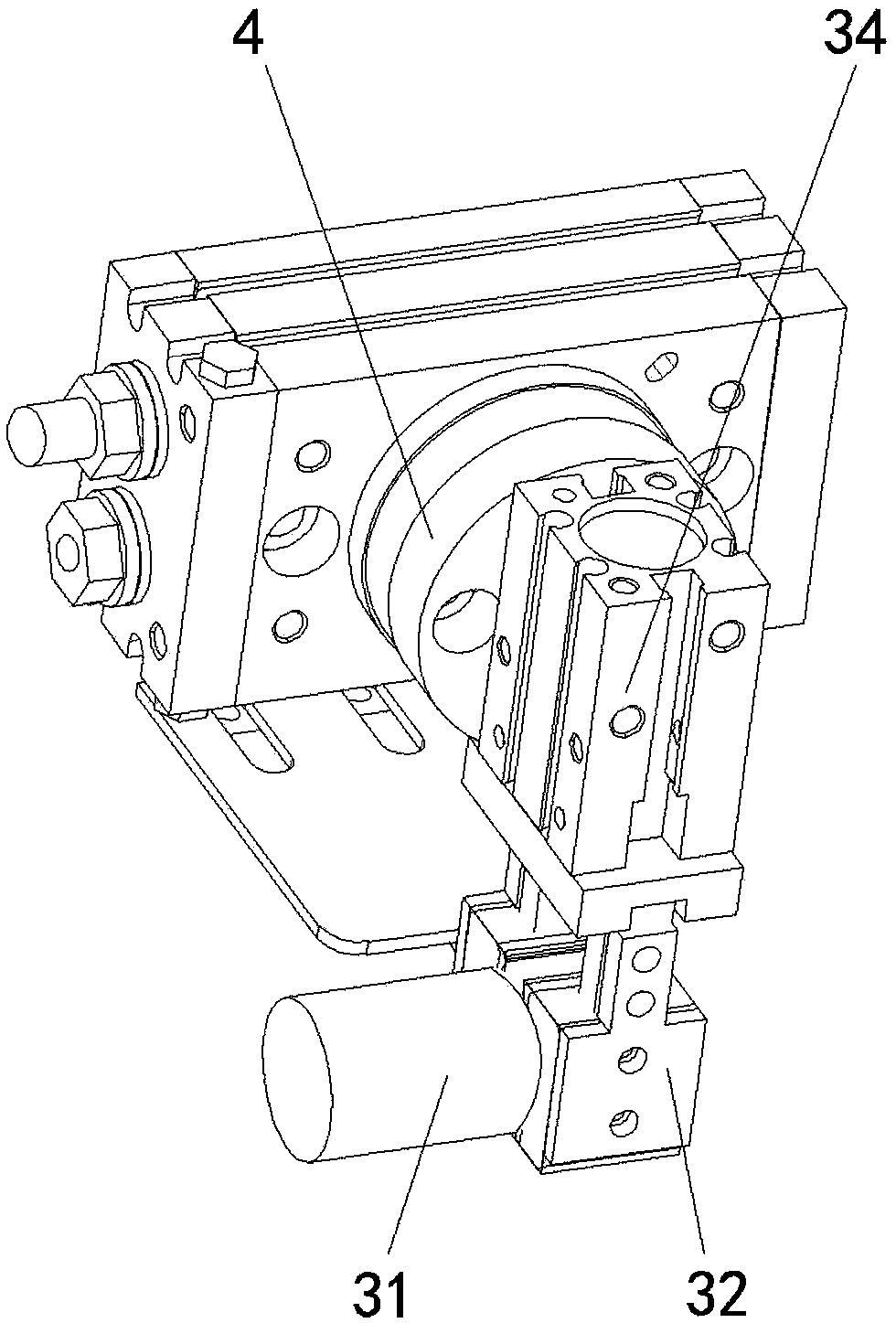

[0022] refer to Figure 1-Figure 2 , a kind of automatic feeding machine with spring compression and length inspection, including a detection turntable 101, including a conveying mechanism 1, a vibrating hopper 2 located at one end of the conveying mechanism 1, and a clamping mechanism 3 located at the other end of the conveying mechanism 1; the clamping mechanism 3 rotates The mechanism 4 rotates to a vertical state or a horizontal state, and the rotating mechanism 4 is installed on the position adjustment mechanism 5; the spring is sent to the conveying mechanism 1 through the vibrating hopper 2, and the conveying mechanism 1 adopts a conveyor belt, and the conveying mechanism 1 conveys the spring to the clamping At the 3 places of the mechanism, the clamping mechanism 3 clamps the spring placed horizontally, and turns the spring to a vertical state through the rotating mechanism 4, and places it on the detection turntable 101 for detection, which changes the working method o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com