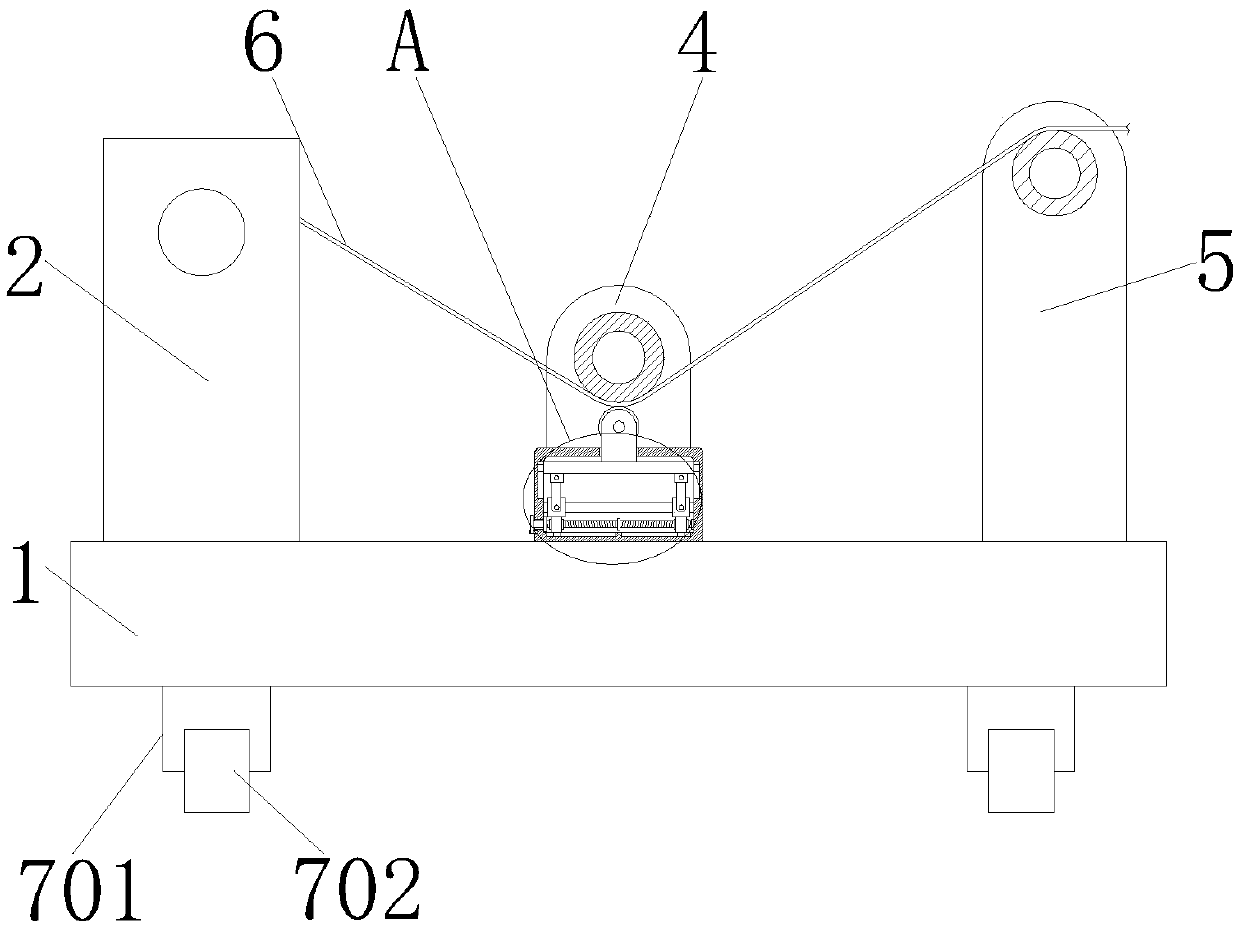

Lithium battery membrane rolling device

A technology of lithium battery diaphragm and winding device, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of not being able to prevent wrinkles, and achieve the effect of saving time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

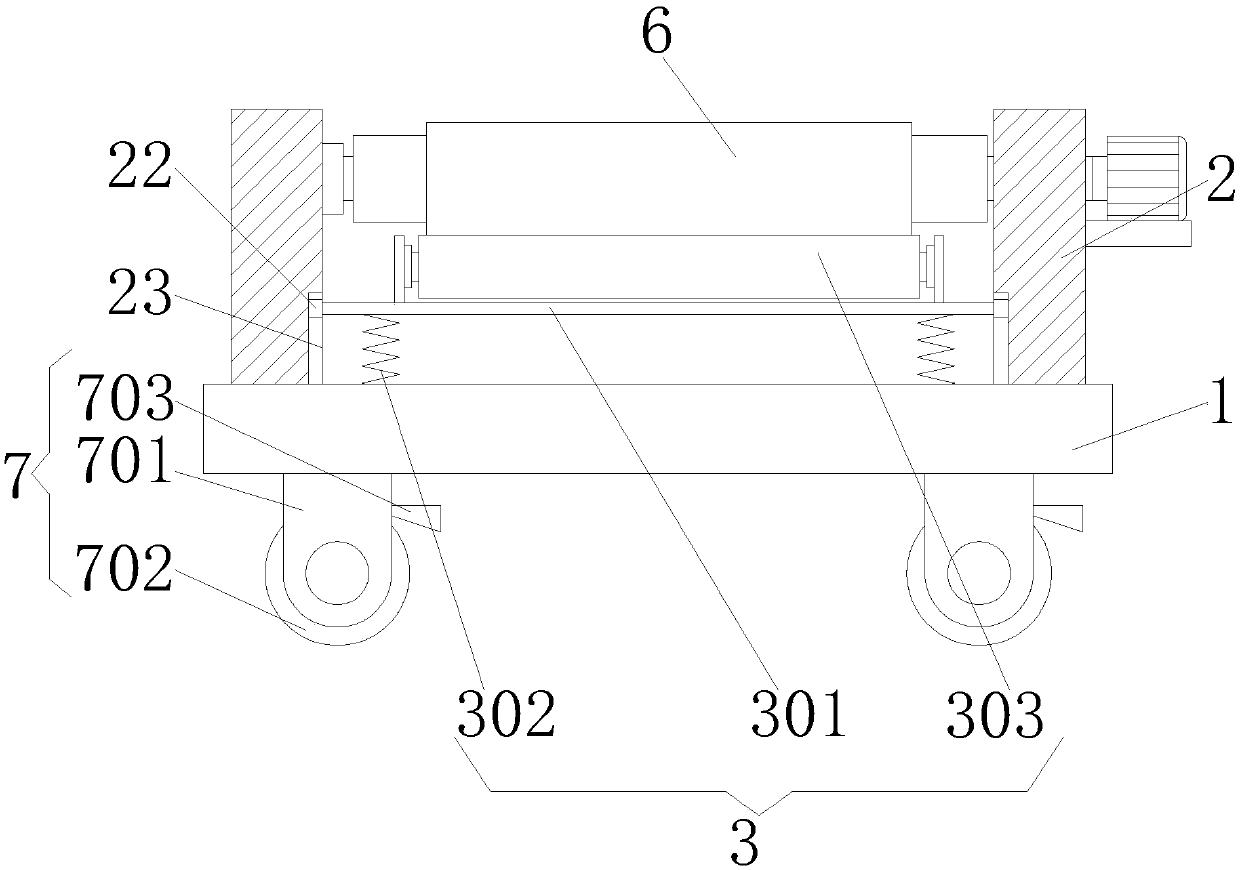

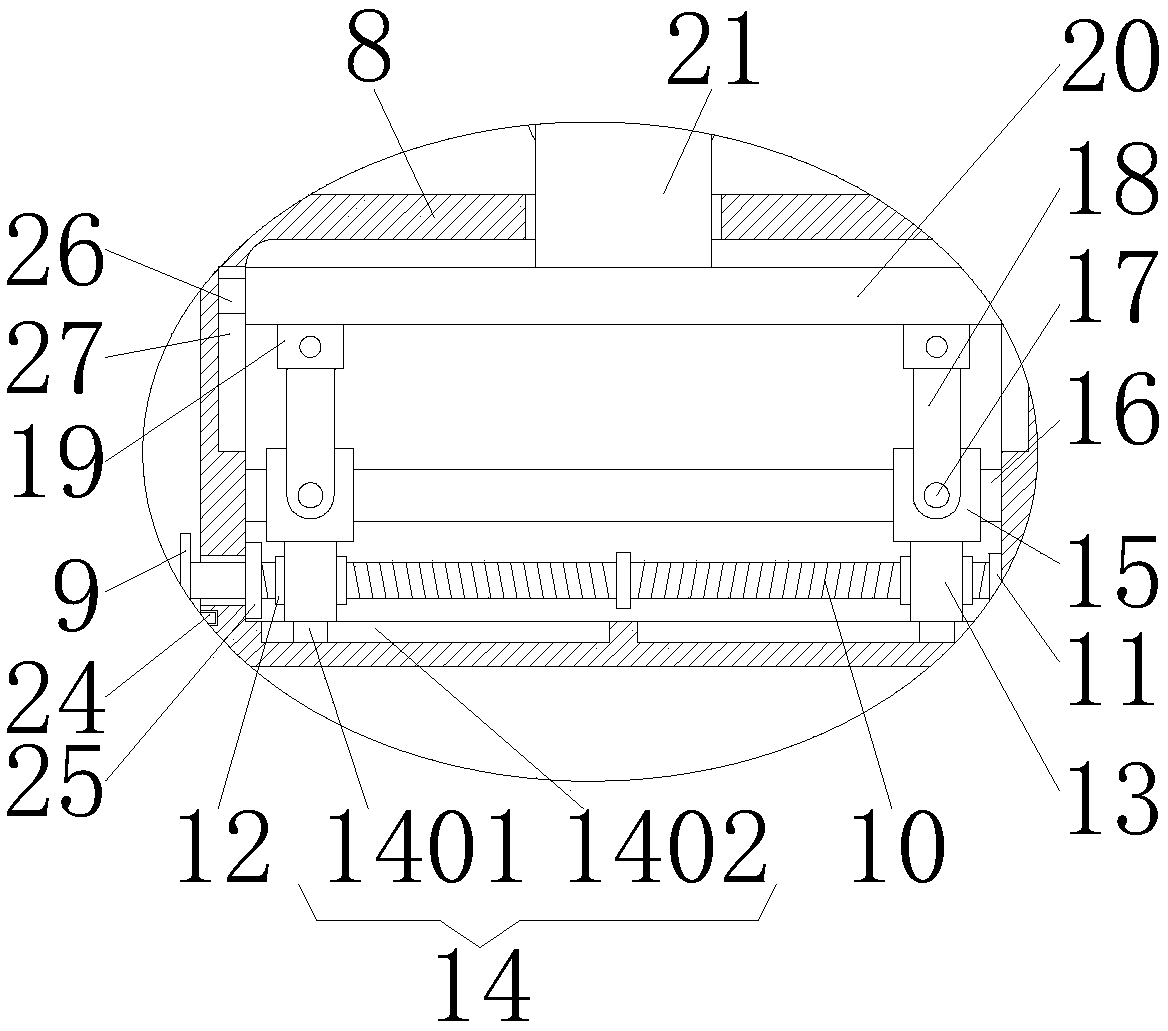

[0033] Embodiment 2: The difference from Embodiment 1 is that the clamping mechanism 3 includes a horizontal plate 301, the front end and the rear end of the bottom of the horizontal plate 301 are fixedly connected with a spring 302, the bottom of the spring 302 is fixedly connected with the bottom plate 1, and the horizontal plate 301 A clamping roller 303 is fixedly connected to the top of the clamping roller 303, and the top of the clamping roller 303 is in contact with the diaphragm body 6. By setting a horizontal plate 301, a spring 302 and a clamping roller 303, when the winding device body 2 is winding the diaphragm body 6, The clamping roller 303 is lowered, the lowering of the clamping roller 303 drives the lowering of the horizontal plate 301, and the lowering of the horizontal plate 301 compresses the spring 302. There is no corresponding clamping mechanism on the market. This mechanism can prevent the winding device body 2 from winding the diaphragm body At 6 o'cloc...

Embodiment 3

[0034] Embodiment 3: The difference from Embodiment 1 is that the moving mechanism 7 includes a leg 701, the bottom of the leg 701 is movably connected with a roller 702, the back of the leg 701 is provided with a buckle 703, and by setting the leg 701, the roller 702 and buckle 703, when the user needs to move, the user only needs to push the device to roll on the ground through the roller 702, the roller 702 drives the leg 701 to move, and the leg 701 drives the device to move, and when it does not need to move, the buckle 703 is used to The roller 701 is fixed, compared with the forklift moving mechanism on the market, it is convenient for the user to push, and the device can be fixed to move in a small space, and the forklift cannot enter the small space, which sometimes requires the user's manpower move.

Embodiment 4

[0035] Embodiment 4: The difference from Embodiment 2 is that: the front and back of the horizontal plate 301 are fixedly connected with sliders 22, and the inside of the winding device body 2 is provided with a chute 23 at a position corresponding to the slider 22, and the chute 23 Slidingly connected with the slider 22, by setting the slider 22 and the chute 23, the slider 22 can be driven to move inside the chute 23 when the horizontal plate 301 moves up or down. Compared with the slide rail mechanism on the market, This mechanism can not only protect the horizontal plate 301, but also fix the horizontal plate 301 to prevent the horizontal plate 301 from tilting. The device body 2 is protected, but the horizontal plate 3 cannot be protected and fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com