Refining waste water biochemical system universal defoaming agent and preparation method thereof

A general-purpose, defoamer technology, used in chemical instruments and methods, separation methods, foam dispersion/prevention, etc., can solve the problems of reducing COD removal efficiency, affecting water heat dissipation, and increasing water temperature, reducing the surface freedom of foam. performance, improve stability, and reduce usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: The general-purpose defoamer used in the wastewater biochemical treatment system in the refining and chemical industry of the present invention, calculated by mass percentage, has the following composition: tetradecyl alcohol 8%, methanol 2%, polyether modified 20% , 1% hydrochloric acid, 1% CMC, and the balance is deionized water.

[0016] Preparation process: Add polyether modified product, CMC, and tetradecyl alcohol in the reaction kettle according to the weight ratio, stir evenly, heat up to 65°C for aging reaction, and the aging time is 2 hours; then cool to room temperature, add while stirring Deionized water, hydrochloric acid, and methanol were kept stirring for 30 minutes to obtain a general-purpose defoamer product.

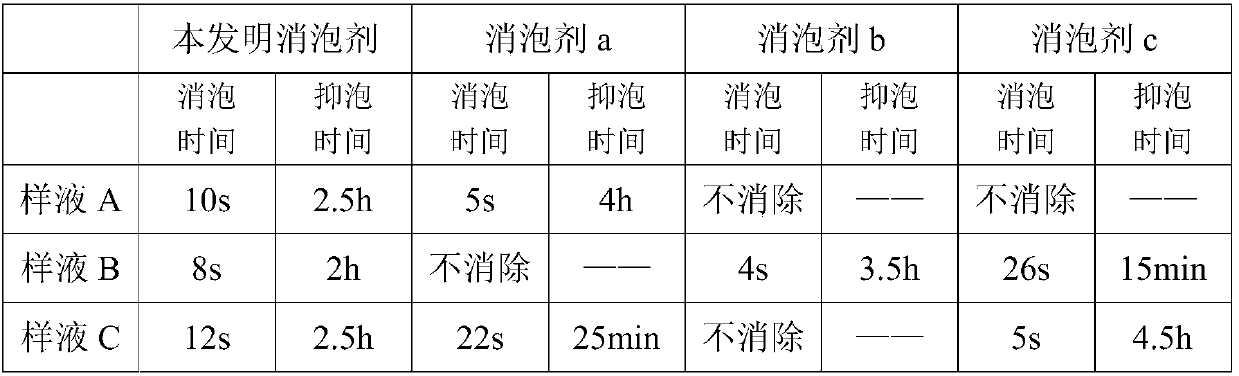

[0017] Examples of effect tests:

[0018] Water samples from the on-site wastewater biochemical treatment systems of three refineries were used as test sample liquids, namely A, B, and C. A quartz glass cylinder with a diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com