Large-size silicon carbide aerogel and preparation method thereof

A silicon carbide and aerogel technology, which is applied in the field of silicon carbide aerogel preparation, can solve the problems of complex preparation process, high cost, brittleness and the like, and achieves the effects of simple process, low equipment requirements and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

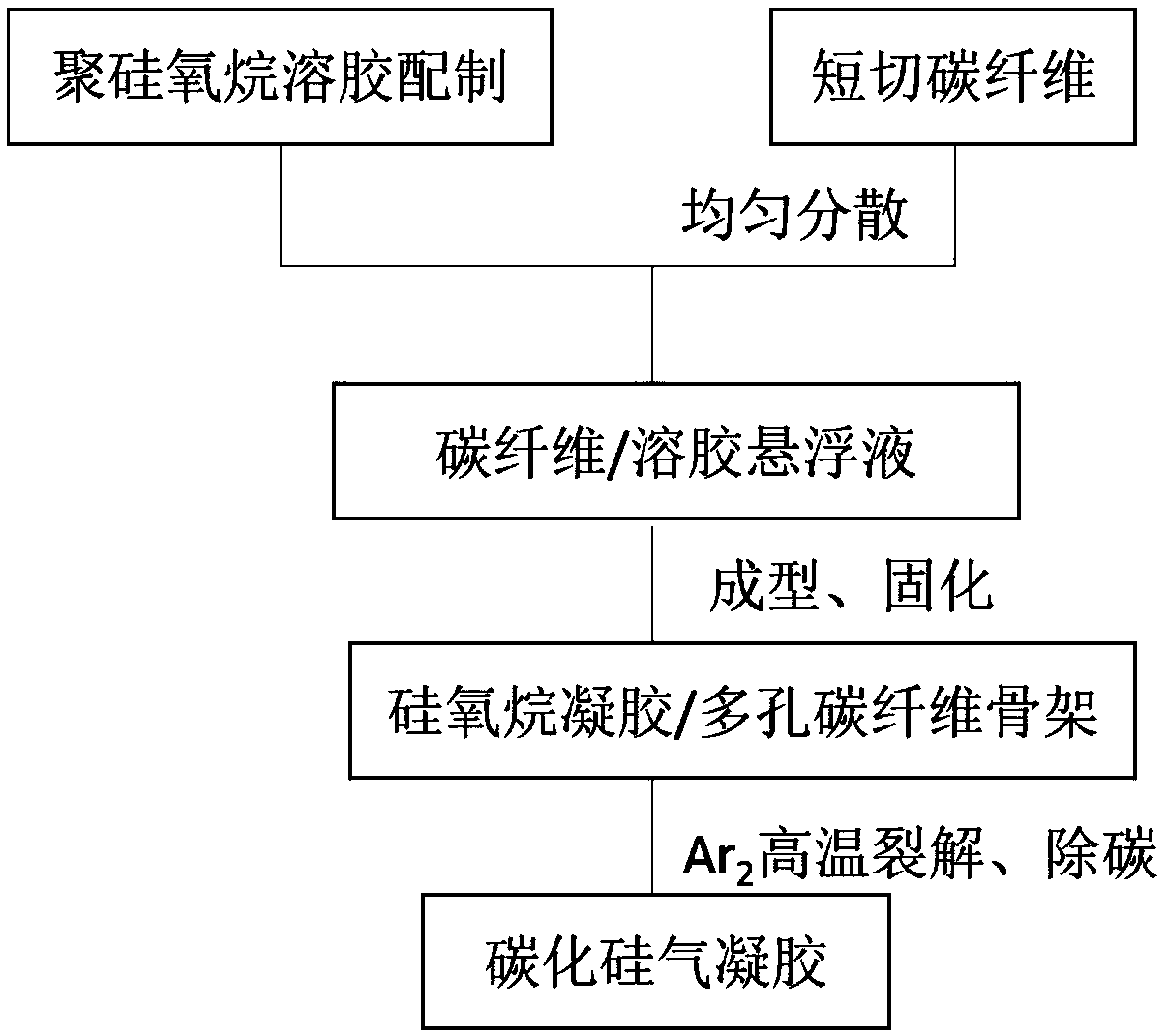

Method used

Image

Examples

Embodiment 1

[0043] This embodiment has prepared the density is 2mg / cm 3 Silicon carbide airgel, the specific steps are as follows:

[0044] 1) Using dimethyldimethoxysilane (mass fraction 10wt.%) as a sol raw material, water as a crosslinking agent (mass fraction 10wt.%) and absolute ethanol as a solvent (mass fraction 80wt.%) to prepare silicon Oxygen sol;

[0045] 2) Disperse 2g of chopped carbon fibers (length about 1mm, mass fraction 1wt.%) in 100ml of silica sol, and perform mechanical stirring for 10min, so that the chopped carbon fibers are uniformly dispersed in the siloxane sol;

[0046] 3) The method of vacuum filtration is adopted to make the carbon fibers dispersed in the sol overlap each other into a three-dimensional structure block;

[0047] 4) Heating to the curing temperature (100°C) in the air, and heat preservation for 4 hours;

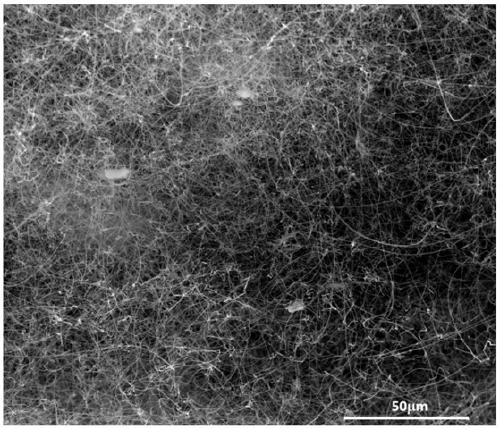

[0048] 5) The temperature is raised to 1200°C in argon with a pressure of 0.1Mpa, and the temperature is kept for 2 hours, and the gel is c...

Embodiment 2

[0051] This embodiment prepared 4mg / cm 3 Silicon carbide airgel, the specific steps are as follows:

[0052] 1) Using methyltrimethoxysilane (mass fraction 10wt.%) sol as raw material, water as crosslinking agent (mass fraction 70wt.%) and absolute ethanol as solvent (mass fraction 20wt.%) to prepare siloxane sol ;

[0053] 2) Disperse 2g of chopped carbon fibers (length about 1mm, mass fraction 2wt.%) in 100ml of silica sol, and perform ultrasonication for 15min, so that the chopped carbon fibers are uniformly dispersed in the siloxane sol;

[0054] 3) Using the method of vacuum filtration, the chopped carbon fibers dispersed in the sol are overlapped to form a three-dimensional block;

[0055] 4) Heating to the curing temperature (100°C) in the air, and heat preservation for 4 hours;

[0056] 5) The temperature is raised to 1500° C. in argon with a pressure of 0.1 MPa, and the temperature is kept for 2 hours, and the gel is cracked to form silicon carbide nanowires;

[0...

Embodiment 3

[0059] This embodiment prepared 15mg / cm 3 Silicon carbide airgel, the specific steps are as follows:

[0060] 1) Using methyltrimethoxysilane (mass fraction 40wt.%) sol as raw material, water as crosslinking agent (mass fraction 50wt.%) and absolute ethanol as solvent (mass fraction 10wt.%) to prepare siloxane sol ;

[0061] 2) Disperse 2g of chopped carbon fibers (length about 1mm, mass fraction 2wt.%) in 100ml of silica sol, and perform ultrasonication for 15min, so that the chopped carbon fibers are uniformly dispersed in the siloxane sol;

[0062] 3) Using the method of vacuum filtration, the chopped carbon fibers dispersed in the sol are overlapped to form a three-dimensional block;

[0063] 4) Apply a pressure of 10kPa to the block;

[0064] 5) Heating to the curing temperature (100°C) in the air, and heat preservation treatment for 4 hours;

[0065] 6) In argon with a pressure of 0.25 MPa, the temperature is raised to 1550 ° C, and the temperature is kept for 2 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com