A yarn splitting device

A technology of yarn separation and thread separation, which is applied to textiles and papermaking, etc., can solve the problems of easy yarn knotting, simple structure and easy thread breakage, etc., and achieve the effects of high yarn separation efficiency, simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

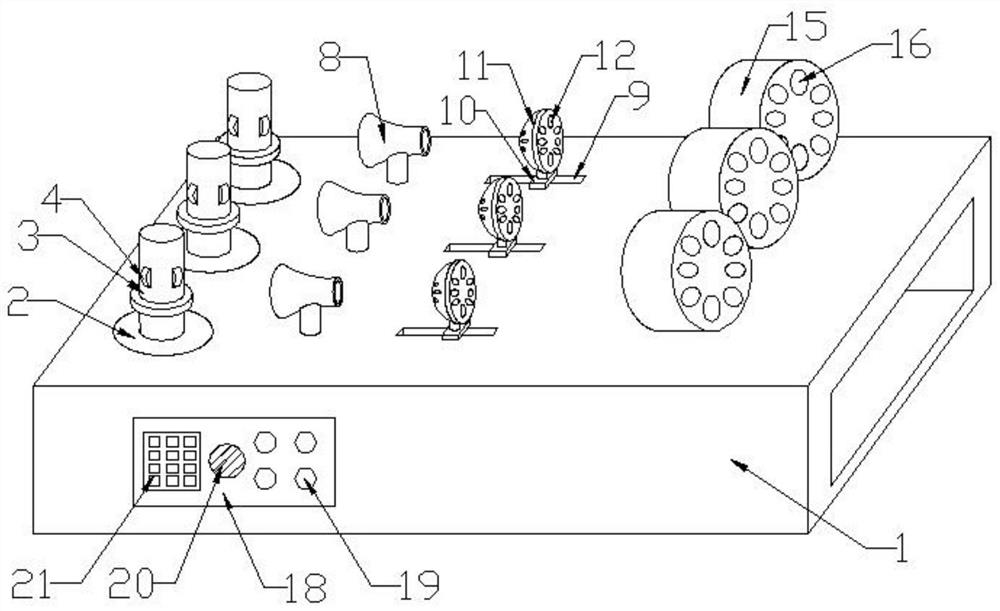

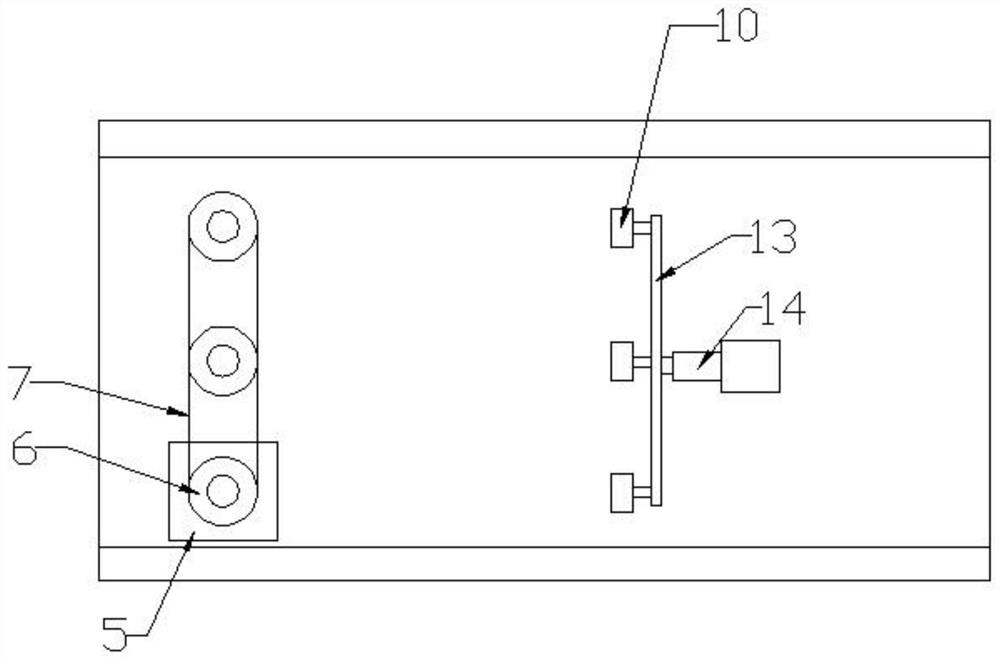

[0025] Such as Figure 1-4 As shown, a yarn splitting device includes a workbench 1, a pay-off shaft 3, a servo motor 5, a wire horn 8, and a photoelectric switch 17. A row of several turntables 2 are installed on the workbench 1, and each turntable 2 is A pay-off shaft 3 is welded, and four blocks 4 are installed on the pay-off shaft 3. A row of wire horns 8, a row of branching heads 11, and a row of wire drums 15 are successively arranged on one side of a row of turntables 2. The wire horns The cylinder 8 is welded on the workbench 1 through the support rod, the branch wire 11 is welded on the slider 10 through the support rod, the slider 10 is installed in the chute 9 set on the workbench 1, and the wire barrel 15 is welded on the workbench 1 .

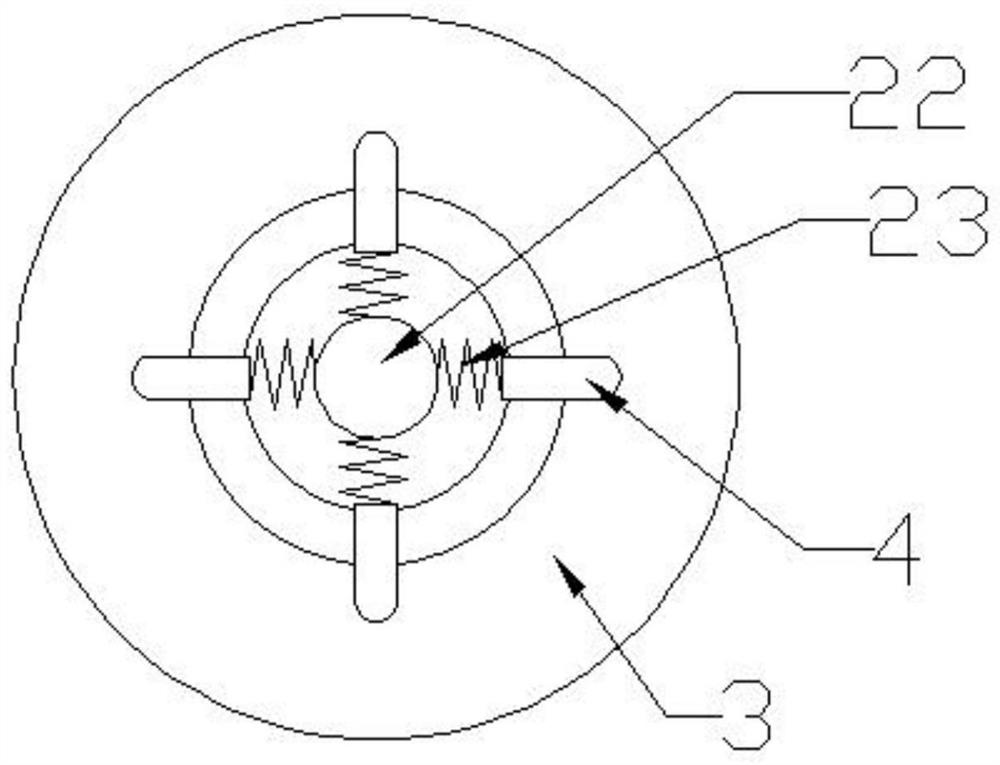

[0026] Each pay-off shaft 3 is provided with a vertical rod 22, and the four blocks 4 are connected to the vertical rod 22 by connecting springs 23. The elastic force makes the clamping block 4 be pressed outwards, thereby blocki...

Embodiment 2

[0030] Such as Figure 1-4 As shown, the wire trumpet 8 is a horn-shaped wire barrel, and its horn-shaped opening is facing the pay-off shaft 3, and the branching head 11 is a lotus-shaped cylinder with one side protruding, and its protruding side is facing To wire trumpet 8, several branch holes 12 are arranged on branch head 11, and several wire holes 16 are correspondingly arranged on wire barrel 15, and photoelectric switch 17 is all inlaid in the inner wall of each wire hole 16.

[0031] Several sliders 10 are all connected to the same connecting rod 13, the bottom end of the workbench 1 is equipped with an electric push rod 14 through bolts, and the connecting rod 13 is installed on the piston end of the electric push rod 14 through bolts. Telescoping drives the slider 10 to move back and forth in the chute 9, and then makes the branching head 11 close to or away from the wire horn 8.

[0032] One side of workbench 1 is equipped with control box 18, and control box 18 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com