Cooling method of cooling system manipulated by AMR processor

An ARM processor and processor technology, applied in the electrical field, can solve the problems of increasing the number of implementation and maintenance, increasing the cost, and increasing the difficulty of wire erection, so as to achieve uncomplicated line erection, ensure efficiency and cycle execution loss , Reduce the effect of execution loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

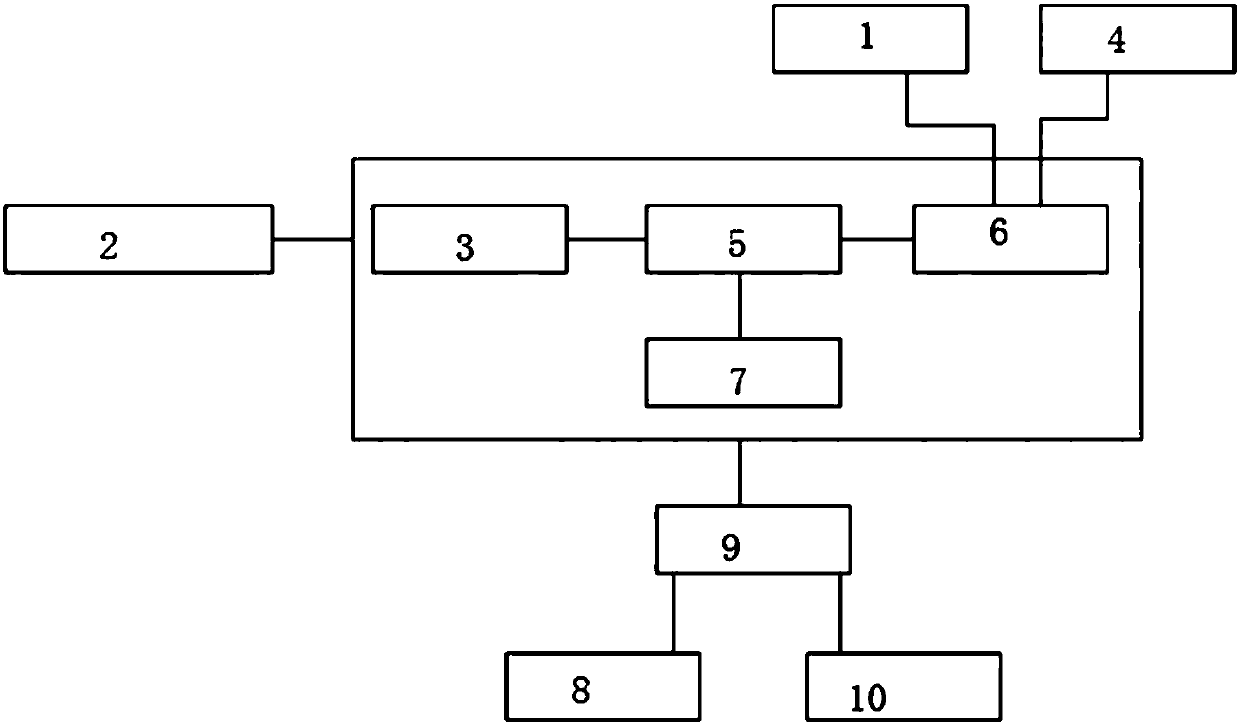

[0024] Such as figure 1 As shown, the cooling method of the cooling system operated by the ARM processor, the cooling system has several exhaust machines 1; a team of exhaust machines 1 is equipped with a motor processor 2; the cooling system control system also has:

[0025] A heat monitor-3 used to check the heat of the air intake hole of the cooling system;

[0026] The heat monitor II 4 used to check the heat of the exhaust hole of the cooling system;

[0027] ARM processor 5; this ARM processor 5 has core unit 6, WIFI component 7, duplex transmission end 8; Analog component 9; Described analog component 9 links to each other with heat monitor one, heat monitor two respectively; Described The duplex transmitting end 8 is connected to each motor processor 2 respectively;

[0028] The input interface component used to transmit messages with the ARM processor 5; the input interface component has buttons for manipulating the operation and termination of the exhaust machine 1...

Embodiment 2

[0035] Such as figure 1 As shown, the cooling method of the cooling system operated by the ARM processor, the cooling system has several exhaust machines 1; a team of exhaust machines 1 is equipped with a motor processor 2; the cooling system control system also has:

[0036] A heat monitor-3 used to check the heat of the air intake hole of the cooling system;

[0037] The heat monitor II 4 used to check the heat of the exhaust hole of the cooling system;

[0038] ARM processor 5; this ARM processor 5 has core unit 6, WIFI component 7, duplex transmission end 8; Analog component 9; Described analog component 9 links to each other with heat monitor one, heat monitor two respectively; Described The duplex transmitting end 8 is connected to each motor processor 2 respectively;

[0039] The input interface component used to transmit messages with the ARM processor 5; the input interface component has buttons for manipulating the operation and termination of the exhaust machine 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com