Method for reducing laser detonation energy

A laser and energy technology, used in blasting tubes, weapon accessories, offensive equipment, etc., can solve the problems of low conversion efficiency of flyer targets, restricting the engineering application of laser-driven flyer initiation technology, etc., to improve safety and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

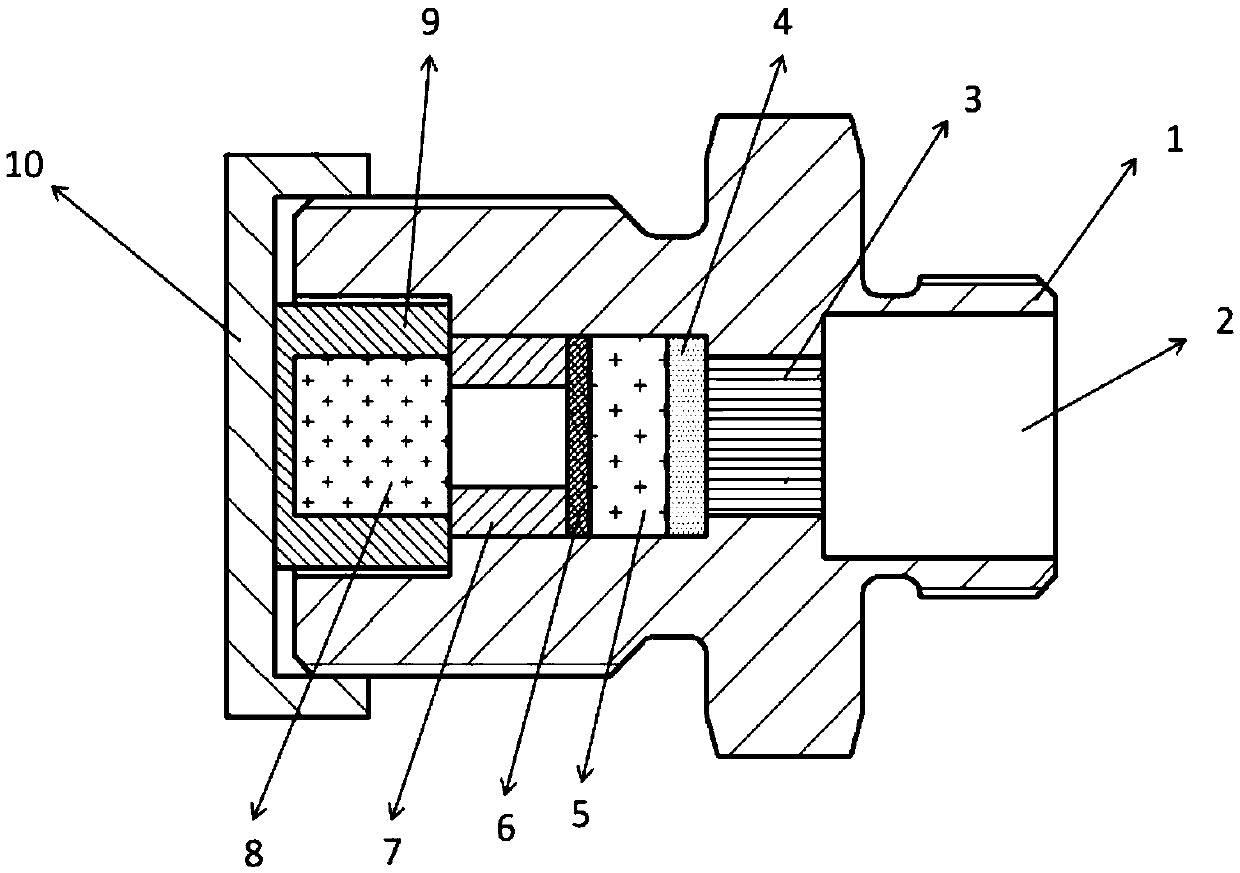

[0023] A method for reducing the energy of laser detonation, based on a low-energy laser detonator, mainly transmits the laser light to the ignition powder 4 through the optical fiber 2 and ignites the ignition powder 4, and utilizes the combustion-to-detonation design, and the ignition powder 4 ignites the initiation powder 5. The starting charge 5 undergoes a combustion-to-detonation process to realize the detonation output of the starting charge 5, and then drives the metal flyer 6 through the detonation of the starting charge 5, so that the metal flyer 6 collides at a high speed and detonates the insensitive explosive 8 , and then realize the low-energy detonation of the insensitive explosive 8.

[0024] Specifically, such as figure 1 Shown is the specific structure of the low-energy laser detonator. The low-energy laser detonator includes a housing 1, an optical fiber 2, a self-focusing optical mirror 3, an accelerating chamber 7, a metal flyer 6, a charge ring 9 and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com