Direct current blow-type gust wind tunnel with bypass revolving door

A revolving door and gust technology, applied in the field of wind engineering, can solve problems such as inability to fully simulate random gusts in the atmospheric boundary layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

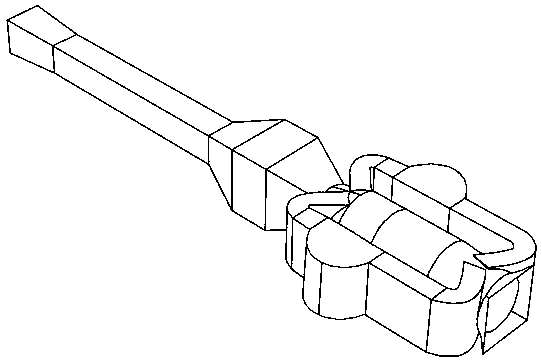

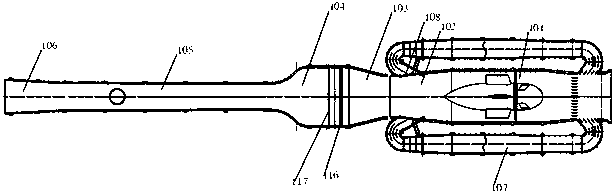

[0039] see figure 1 and figure 2 , the gust wind tunnel of the embodiment of the present invention comprises:

[0040] The power section 101, the diffuser section 103, the stable contraction section 104, the test section 105 and the outlet diffuser section 106 are connected in sequence; specifically, each of the above independent functional sections can be welded or screwed into an integral wind tunnel. Wherein: the power section 101 is communicated with a bypass section 107 , and the bypass section 107 is connected with the power section 101 with a shunt door 108 . One end of the bypass section is connected to the outlet end of the power section (also referred to as the diversion section 102 ) and a diversion door is provided at the communication point. By opening the diversion door, the air flow can be diverted from the main channel to the bypass section. The other end of the bypass section communicates with the inlet end of the power section.

[0041] Optionally, in ord...

Embodiment 2

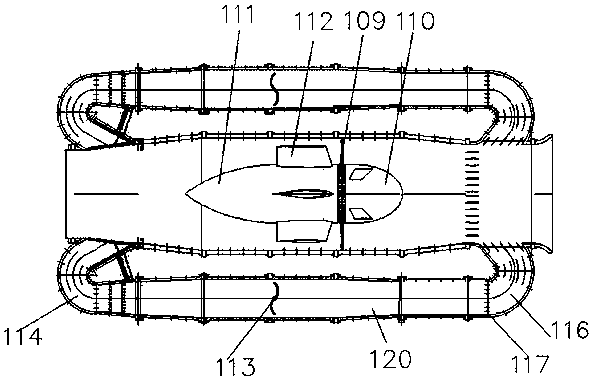

[0051] In this example, if image 3 As shown, optional bypass section 107 includes: corner front section 114 , bypass main section 120 , and corner rear section 116 . Wherein the front corner section 114 and the rear corner section 116 are all used to communicate with the power section 101; Axial. Moreover, the rotary throttle valve 113 is disposed inside the bypass main section 120 .

Embodiment 3

[0053] In this example, if image 3 As shown, the front section 114 of the corner and the rear section 116 of the corner are optionally provided with deflectors, which are used to guide the airflow and reduce the energy loss caused by the sudden change of the airflow direction. When the diverter door 108 is opened, the corner front section 114 smoothly introduces the diverted airflow to the bypass main section 120 to reduce the loss of airflow energy. The main bypass section 120 and the power section 101 are axially parallel to each other, and the rotary cut-off door 113 inside the bypass main section 120 makes the airflow velocity in the main channel change rapidly to generate gusts of wind. Then it flows back into the power section 101 through the corner rear section 116 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com