Memory alloy pipeline valve

A technology for pipeline valves and memory alloys, applied in valve details, multi-way valves, control valves, etc., can solve the problems of inconvenient automatic pressure relief and single use mode, and achieve improved safety, high adjustability, and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0047] Some pipeline valves, usually one-way valves or two-way valves, cannot switch between the two valves under different water temperature conditions. Limit the role of some internal components, and the scope of application is low;

[0048] At the same time, some existing valves are less safe when in use, and cannot automatically relieve pressure when the water pressure is too high, which may easily cause pipeline rupture. To fully clean up, the inventor has proposed a memory alloy pipeline valve to solve the above problems.

[0049] The present invention provides the following preferred embodiments

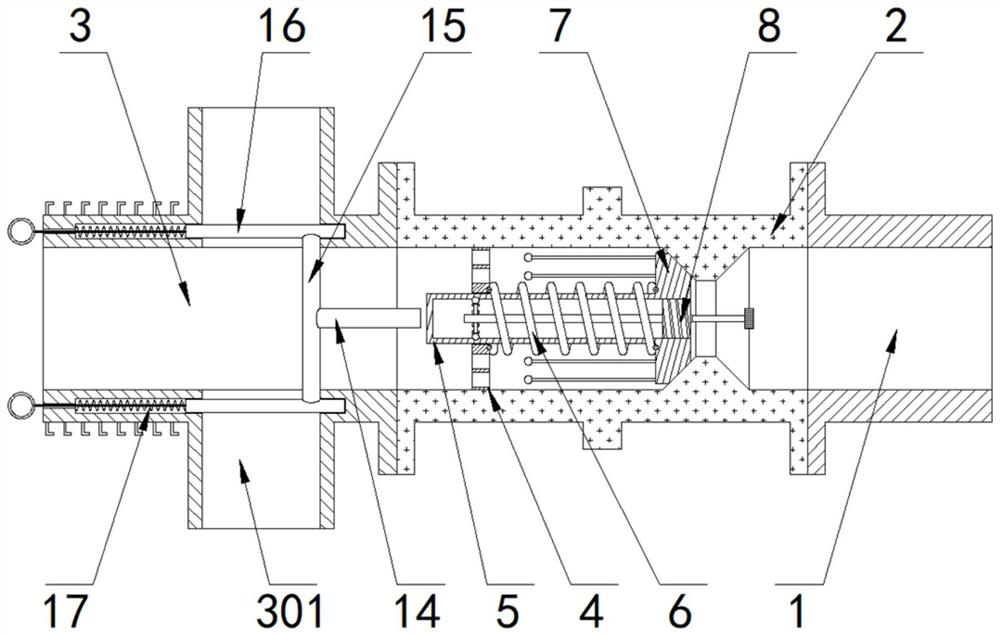

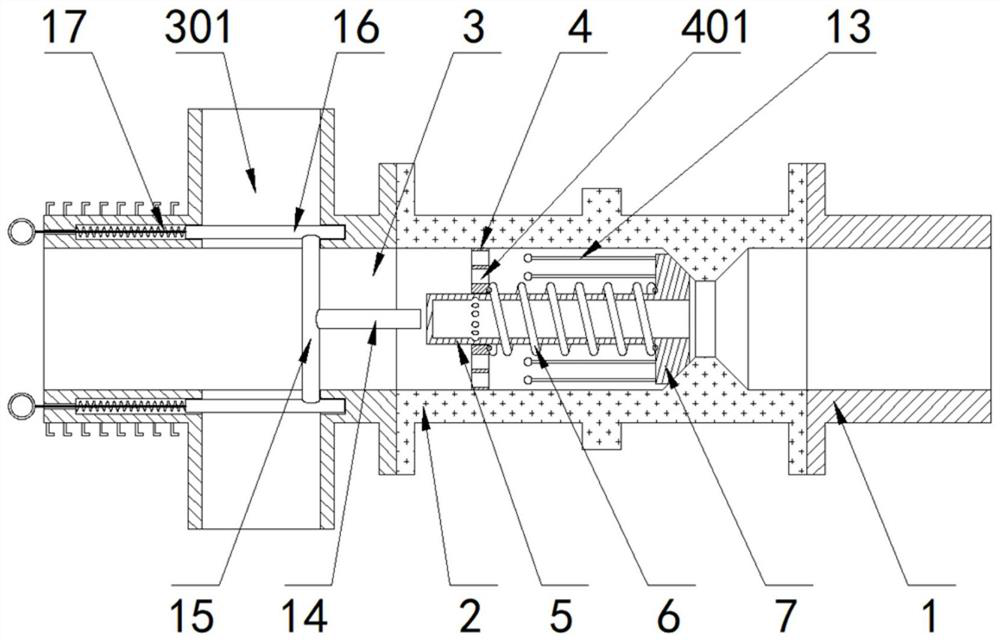

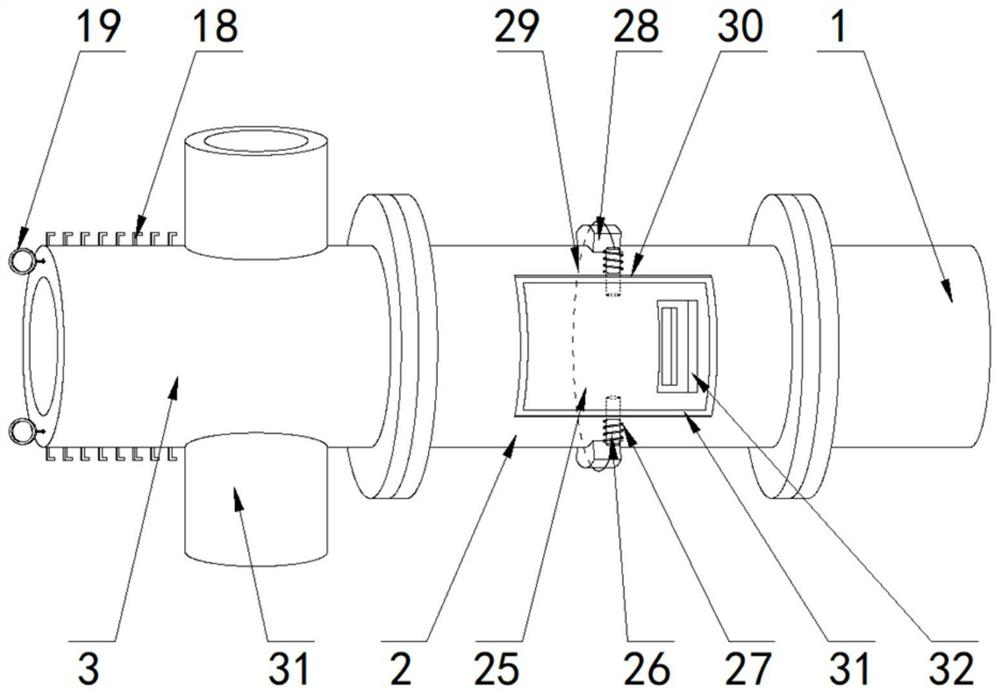

[0050] Such as Figure 1-3 with Figure 8 As shown, a memory alloy pipe valve includes a first pipe 1, a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com