Portable fruit hardness detecting instrument

A detection instrument and portable technology, which is applied in the field of portable fruit hardness detection instruments, can solve the problems of inedible fruits and inconsistency of measurement results, and achieve the effects of fast measurement speed, maintaining accuracy, and ensuring accuracy

Pending Publication Date: 2019-04-16

ZHEJIANG UNIV

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] The present invention can realize the consistency of each detection process, and can accurately detect the operation and implementation of different people, and solves the technical problem of inconsistency of measurement results caused by different interference press

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

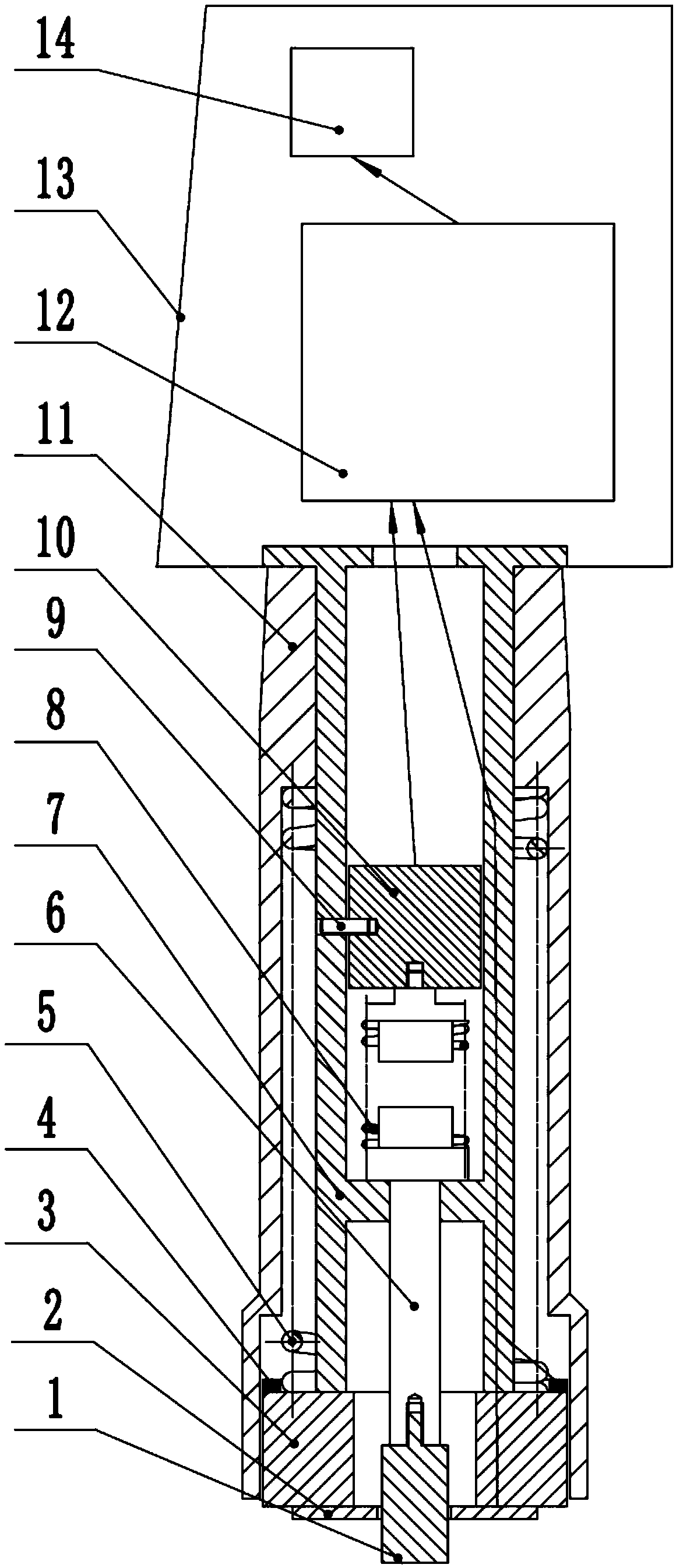

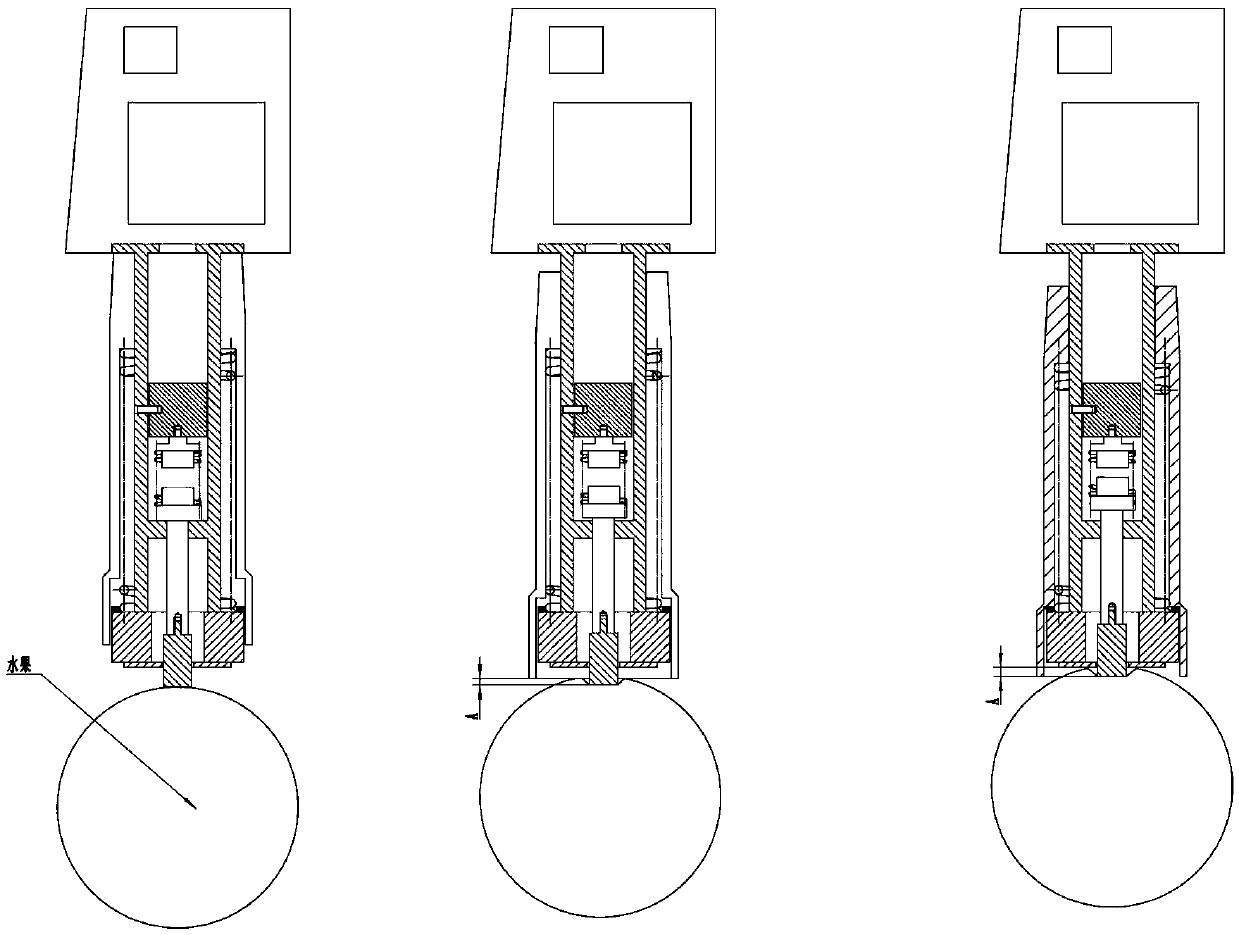

The invention discloses a portable fruit hardness detecting instrument. An outer sleeve is arranged outside an inner sleeve. A spring stop block is fixedly connected to the bottom of the inner sleeve.Two circumferential grooves are formed in the outer sleeve; a first annular step surface and a second annular step surface are formed between the upper circumferential groove and the inner wall of the top of the outer sleeve and between the lower circumferential groove and the inner wall of the top of the outer sleeve respectively. A force applying spring is arranged between the first annular step surface and the spring stop block. When the outer sleeve moves down, the step is stopped and limited by the spring stop block. A pressure sensor is installed in the middle of the inner sleeve and isconnected with a guide rod by an elastic component; and the guide rod is connected with a probe fixedly. A first piezoelectric film is arranged at the spring stop block; and a second piezoelectric film is also arranged on the spring stop block. The portable fruit hardness detecting instrument can be applied to the micro-damage or non-destructive measurement of fruit hardness as well as testing ofthe fruit pulp hardness after peeling. The measurement result is not affected by the manual pressure and loading speed and is accurate. The portable fruit hardness detecting instrument has characteristics of high portability, fast measurement speed, high detection precision, and simple operation and is suitable for the on-site measurement in occasions such as orchards and supermarkets.

Description

technical field [0001] The invention relates to a portable detection instrument, in particular to a portable fruit hardness detection instrument, which is suitable for rapid detection of fruit hardness in orchards, supermarkets and other occasions. Background technique [0002] Fruit is one of the important agricultural products. As a labor-intensive industry, the fruit industry is the third pillar industry after grain and vegetables in the planting industry. The annual output reaches hundreds of millions of tons, and it occupies a very important position in my country's national economy. Every year, 20%-30% of the fruit is wasted due to various reasons, among which the waste caused by improper picking period, long storage time, transportation damage and other reasons accounts for a large proportion. If we can provide portable instruments that can detect the ripeness of fruits in real time in orchards, supermarkets, etc., and help fruit farmers and distributors to reasonably...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/42G01N3/02

CPCG01N3/02G01N3/42G01N2203/0076

Inventor 崔笛王大臣丁城桥冯喆容典

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com