A method for removing cadmium from whole grain rice

A rice and solution technology, which is applied in food ultrasonic treatment, food science, etc., can solve the problems of not considering environmental pollution, reducing the efficiency of cadmium removal in the final product, negative effects, etc., and achieves the effect of easy implementation, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for removing cadmium from whole-grain rice, comprising the steps of:

[0034] (1) Impurity removal: use air separation, magnetic separation, and screening devices to remove gravel and rice husk impurities contained in rice raw materials (cadmium content is 0.65ppm);

[0035] (2) Rice filling and dissolution of metal cadmium: put the impurity-removed rice into a countercurrent elution column, and soak the rice in an aqueous solution containing a complex acid complexing agent and a complex salt for 30 minutes. At the same time, set the ultrasonic power to 12kw and the ultrasonic temperature to 25°C;

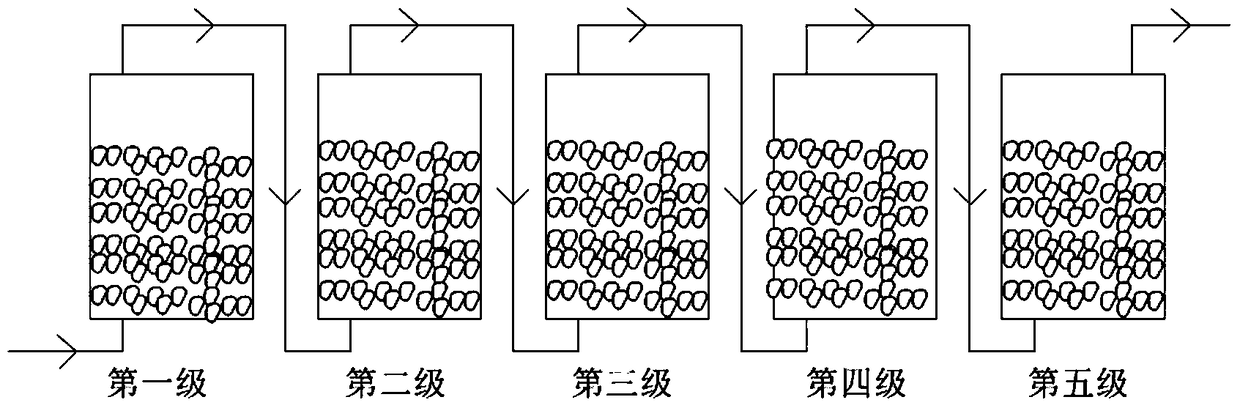

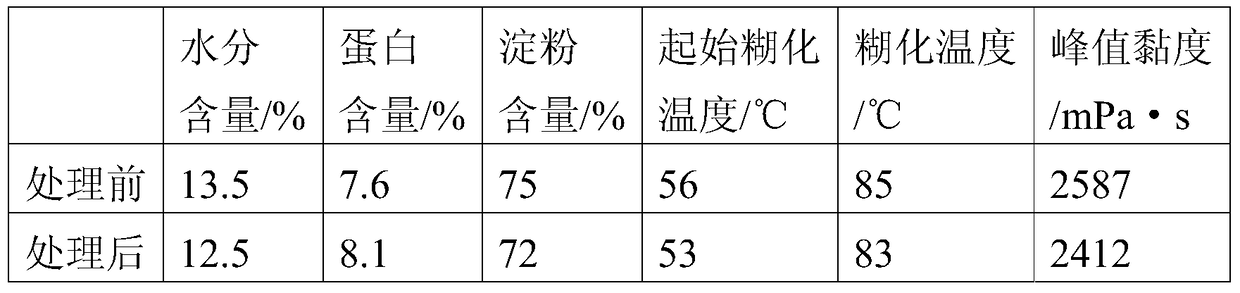

[0036] (3) Separation: adopt the continuous countercurrent washing method, set the five-stage countercurrent elution column, by controlling the flow velocity of the eluting water to be 2mm / s, and monitoring the pH value of the eluting water at the same time to be 6, it will be processed through step (2) The solution containing cadmium in the countercurrent elution ...

Embodiment 2

[0046] A method for removing cadmium from whole-grain rice, comprising the steps of:

[0047] (1) Impurity removal: adopt air separation, magnetic separation, and screening devices to remove gravel and rice husk impurities contained in rice raw materials (cadmium content is 1.8ppm);

[0048] (2) Rice filling and dissolution of metal cadmium: put the impurity-removed rice into a countercurrent elution column, and soak the rice in an aqueous solution containing a complex acid complexing agent and a complex salt for 40 minutes. At the same time, set the ultrasonic power to 14kw and the ultrasonic temperature to 30°C;

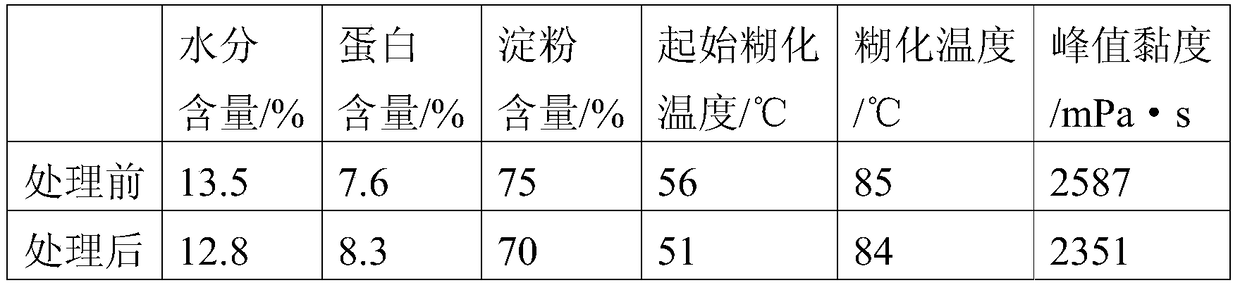

[0049] (3) Separation: adopt continuous countercurrent washing method, set three-stage countercurrent elution column, be 2.5mm / s by controlling the flow rate of eluting water, monitor the pH value of eluting water simultaneously to be 5.5, will go through step (2) The cadmium-containing solution is separated from the rice in the treated countercurrent elution colu...

Embodiment 3

[0059] A method for removing cadmium from whole-grain rice, comprising the steps of:

[0060] (1) Impurity removal: use air separation, magnetic separation, and screening devices to remove gravel and rice husk impurities contained in rice raw materials (cadmium content is 1.2ppm);

[0061] (2) Rice filling and dissolution of metal cadmium: put the impurity-removed rice into a countercurrent elution column, and soak the rice in an aqueous solution containing a complex acid complexing agent and a complex salt for 20 minutes. It is advisable to set the ultrasonic power to 10kw and the ultrasonic temperature to 30°C at the same time;

[0062] (3) Separation: adopt the continuous countercurrent washing method, set the three-stage countercurrent elution column, by controlling the flow rate of the eluting water to be 3mm / s, and monitor the pH value of the eluting water to be 6 at the same time, it will be processed by step (2) The solution containing cadmium in the countercurrent el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com