Novel method for producing probiotic fermented functional sugar-free sugar garlic for diabetes patients

A production method and technology of probiotics, applied in the functions of food ingredients, bacteria used in food preparation, applications, etc., can solve the problems of restricting the edible range and consumption of garlic, difficult to eat in large quantities, affecting communication, etc., and improve human immunity. Strength, not easy to catch cold, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

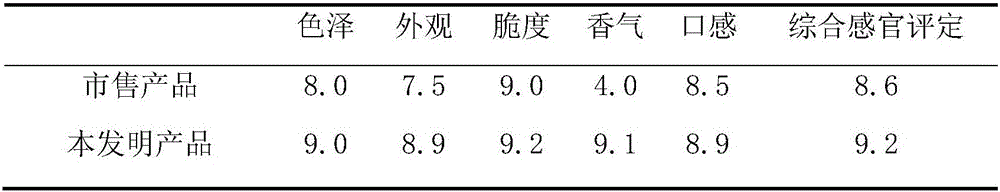

Examples

Embodiment 1

[0030] A production method of novel probiotic fermented functional sugar-free sugar garlic, comprising the following steps:

[0031] Raw material processing: pick the raw garlic, remove the outer skin, wash it with cold boiled water and drain it for later use;

[0032] Preparation of mixed bacteria powder: the mass ratio of Lactobacillus plantarum: Acetobacter is 7:1. The Lactobacillus plantarum is CGMCC NO.9405, and the Gluconacetobacter hansenii is CGMCC NO.1.1811, which are fermented and cultured by a conventional method and freeze-dried to prepare bacterial powder.

[0033] Probiotic fermentation: Weigh 5kg of processed garlic and put it into a container with a cover, add mixed bacteria powder with 0.1% of the mass of garlic, add cold boiled water to submerge the garlic, control the fermentation temperature to 25°C, and ferment for 5 days;

[0034] Pickling: add xylitol and salt for pickling to the container, the mass ratio of garlic: xylitol: salt is 1:0.5:0.002, after f...

Embodiment 2

[0036] A production method of novel probiotic fermented functional sugar-free sugar garlic, comprising the following steps:

[0037] Raw material processing: pick the raw garlic, peel off the outer skin, wash and drain with pure water and set aside;

[0038] Preparation of mixed bacteria powder: the mass ratio of Lactobacillus plantarum: Acetobacter is 6:1. The Lactobacillus plantarum is CGMCC NO.9405, and the Gluconacetobacter hansenii is CGMCC NO.1.1811, which are fermented and cultured by a conventional method and freeze-dried to prepare bacterial powder.

[0039] Probiotic fermentation: Weigh 10kg of processed garlic and put it into a container with a cover, add mixed bacteria powder with 0.05% of the mass of garlic, add pure water to submerge the garlic, control the fermentation temperature to 30°C, and ferment for 3 days;

[0040] Pickling: add xylitol and salt for pickling to the container, the mass ratio of garlic: xylitol: salt is 1:0.41:0.002, after fully dissolving...

Embodiment 3

[0042] A production method of novel probiotic fermented functional sugar-free sugar garlic, comprising the following steps:

[0043] Raw material processing: pick the raw garlic, remove the skin, wash it with sterile water and drain it for later use;

[0044] Preparation of mixed bacteria powder: the mass ratio of Lactobacillus plantarum: Acetobacter is 4:1. The Lactobacillus plantarum is CGMCCNO.9405, which is fermented and cultured by a conventional method and freeze-dried to prepare bacterial powder. Acetobacter is a commercially available active bacterial powder product;

[0045] Probiotic fermentation: Weigh 5 kg of processed garlic and put it into a container with a cover, add 0.2% of garlic mass mixed bacteria powder, add sterile water to submerge the garlic, control the fermentation temperature to 20°C, and ferment for 6 days;

[0046] Pickling: add xylitol and salt for pickling to the container, the mass ratio of garlic: xylitol: salt is 1:0.6:0.005, after fully dissol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com