A fuel cell deflector

A technology of deflectors and diversion grooves, which is applied in the direction of fuel cells, circuits, electrical components, etc., can solve problems such as battery performance, operating efficiency, and manufacturing cost impact, and achieve uniformity of temperature, increase consistency, and reduce temperature poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

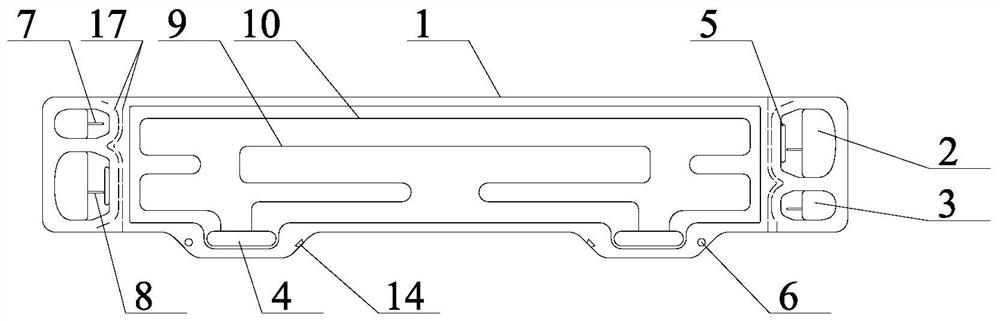

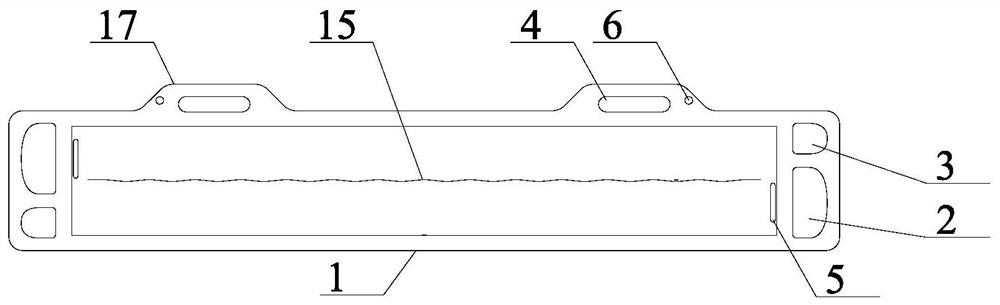

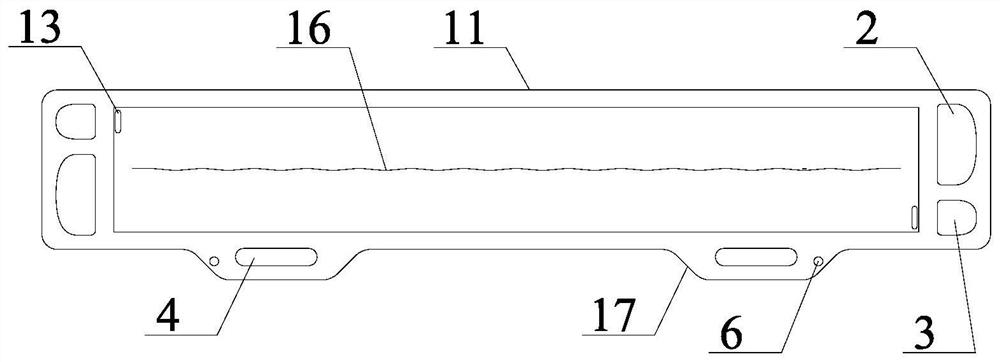

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0026] 1. If Figure 1~4 As shown, it is a fuel cell deflector that is beneficial to improve the consistency of fluid flow rate and temperature distribution. The slot plate 1 and the hydrogen guiding slot plate 11 are composed; the cooling fluid channel 9 is in the interlayer formed by the reverse side of the air guiding slot plate 1 and the reverse side of the hydrogen guiding slot plate 11; The air common channel 2 for air in and out, the hydrogen public channel 3 for hydrogen in and out, the cooling fluid channel 4 for cooling fluid in and out, and the air guide groove 15 for connecting the fluid channel in and out and the fluid channel for connecting in and out The hydrogen diversion groove 16; it is characterized in that, described diversion bipolar plate is generally rectangular, protrudes two protrusions 17 along one side of this cuboi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com