Engine wire harness of V-shaped sixteen-cylinder four-ECU electronic injection machine

A technology of engine and wiring harness, which is applied in the field of V-type sixteen-cylinder four-ECU electronic injection engine wiring harness, can solve the problems that cannot be applied to V-type sixteen-cylinder electronic injection engine, etc., achieve accurate and effective analysis and processing, improve economy, Effect of reducing design cost and cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

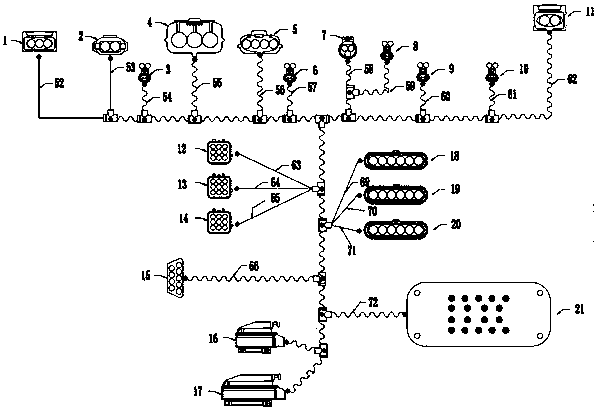

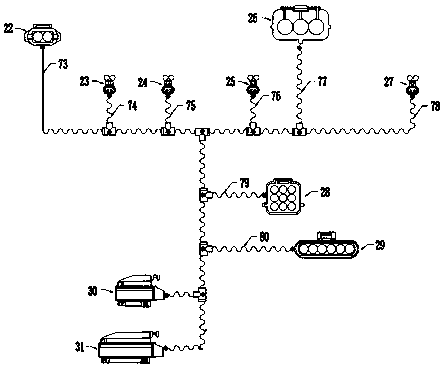

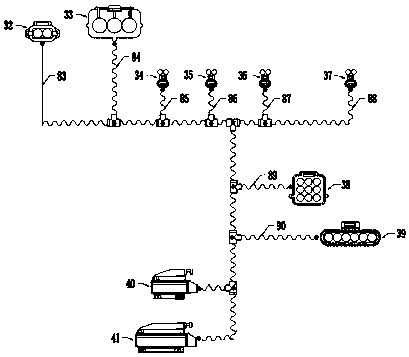

[0085] The present invention will be further described below in conjunction with the accompanying drawings.

[0086] see figure 1 , figure 2 , image 3 and Figure 4 , a V-type sixteen-cylinder four-ECU electric injection engine wiring harness, including a main wiring harness, a first slave wiring harness, a second slave wiring harness and a third slave wiring harness connected to the main wiring harness through an adapter, it is characterized in that the main Harness includes:

[0087] The camshaft position sensor wiring harness 52 connected to the camshaft position sensor joint 1 at one end;

[0088] a first VCV valve wiring harness 53 connected at one end to the first VCV valve joint 2;

[0089] The eight-cylinder fuel injector wiring harness 54 connected to the eight-cylinder fuel injector connector 3 at one end;

[0090] The first rail pressure sensor wiring harness 55 connected to the first rail pressure sensor connector 4 at one end;

[0091] The intake pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com